BTL5-A11-M/U_ _ _ _-P-SA167-S 32

Micropulse Linear Transducer in Profile Housing

5

english

3 Installation (cont.)

3.3 Captive magnets

Lateral forces are to be avoided

when using captive magnets

(

➥➥

➥➥

➥ Figs. 3-6 and 3-7). Connections

are required here which permit the

corresponding degree of freedom

with respect to the direction of

movement of the magnet along the

stroke range. It is assumed that the

BTL5-F-2814-1S magnet is con-

nected to the machine member

using a connecting rod. The

BTL2-GS10...A connecting rod

(

➥➥

➥➥

➥ Fig. 3-8) is available as an ac-

cessory (please indicate length LG

when ordering).

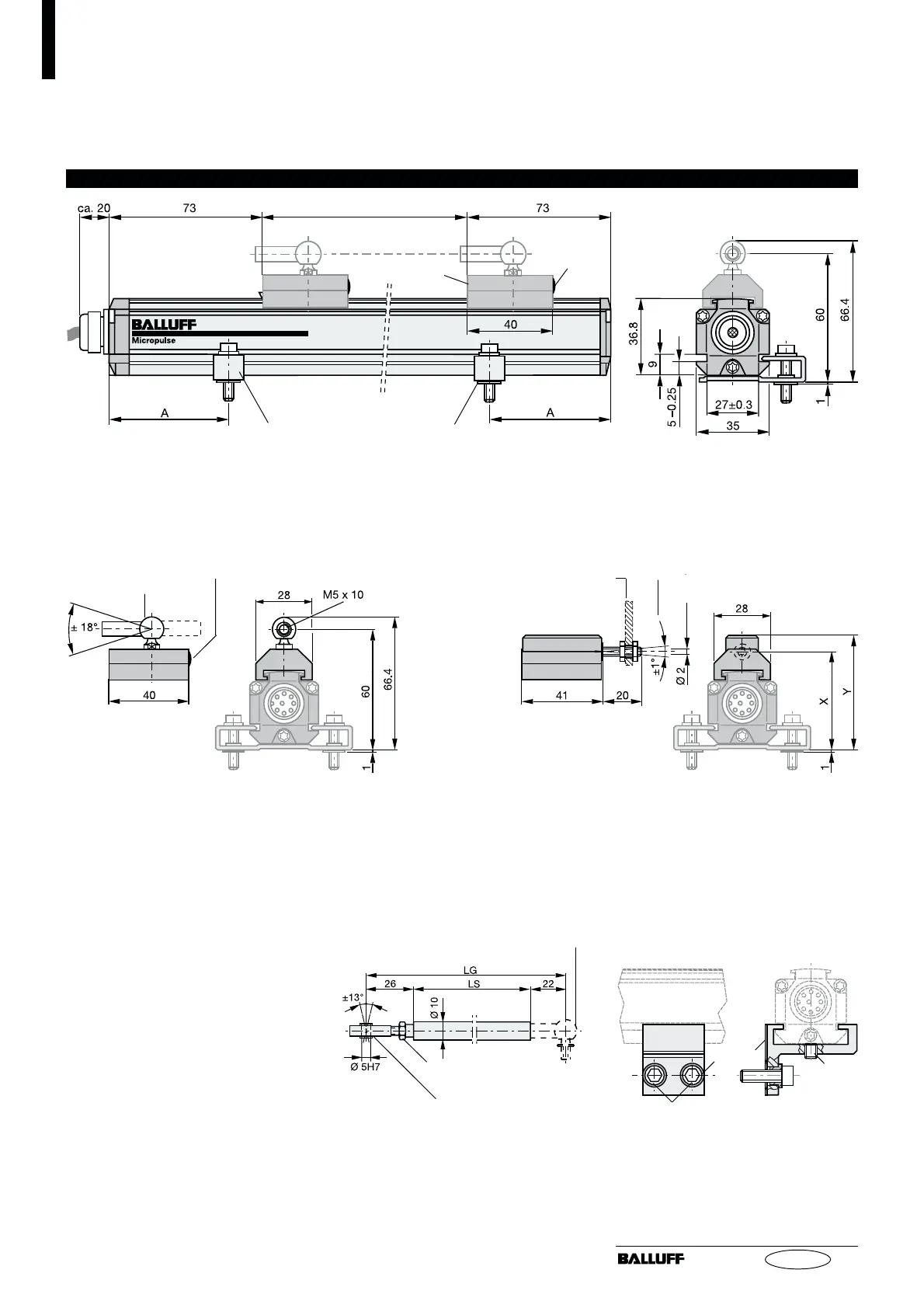

Fig. 3-5: Dimensional drawing (BTL5...P-KA transducer with captive magnet BTL5-F-2814-1S)

Mounting brackets with isolation bushings

and M5 x 22 cylinder head screws, DIN 912,

max. tightening torque 2 Nm

Nominal stroke

Black,

round

marking

Magnet

NL

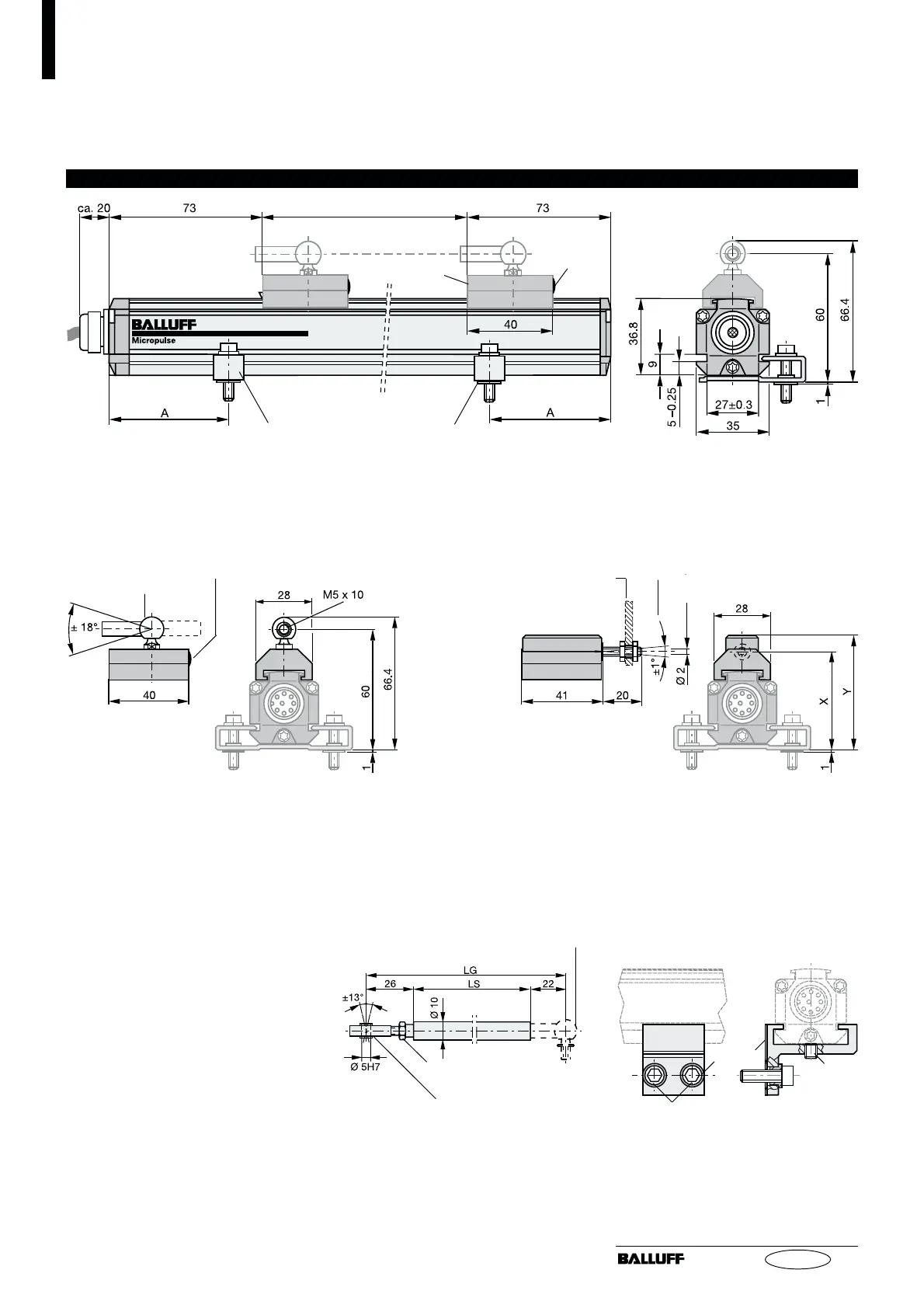

Fig. 3-8: BTL2-GS10-_ _ _ _-A

connecting rod

Jam nut DIN 934 M5

Swivel eye DIN 648

Ball joint "B" DIN 71805, rotates hori-

zontally (part of BTL5-F-2814-1S)

Ball joint "B"

DIN 71805,

rotates horizontally

Black, round

marking

Fig. 3-6: BTL5-F-2814-1S magnet

Fig. 3-7: BTL5-M/N-2814-1S magnet

Mechanically joined to M5

stud using 2 nuts

Max. angle offset

Max. parallel offset

BTL5-M-2814-1S: X = 48.5 Y = 57

BTL5-N-2814-1S: X = 51 Y = 59.5

Fig. 3-9: Mounting angle (optional)

Insula-

tion

Set-

screw

DIN 916

M6 x 10

Screw ISO 4762 M6 x 20

max. torque 2 Nm

3.4 Mounting angle for SA167

Loading...

Loading...