5.3.3 Periodic inspection of motor

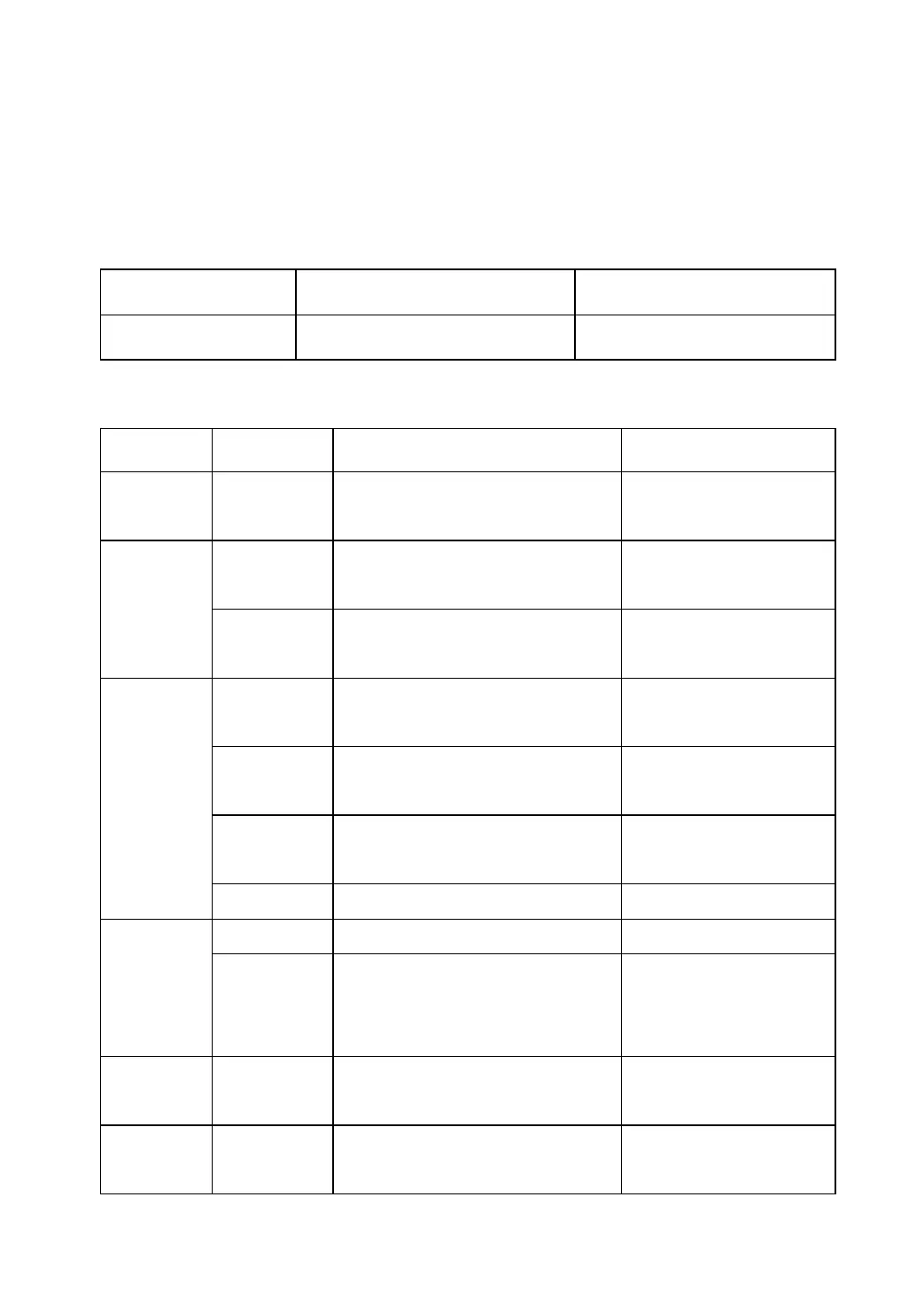

1. Inspecting judgment

Inspection frequency of the motor is related with operation time every day. But at thick

dust or high humidity place, it is necessary to add inspection frequency.

More than 12 hours everyday

Less than 12 hours everyday

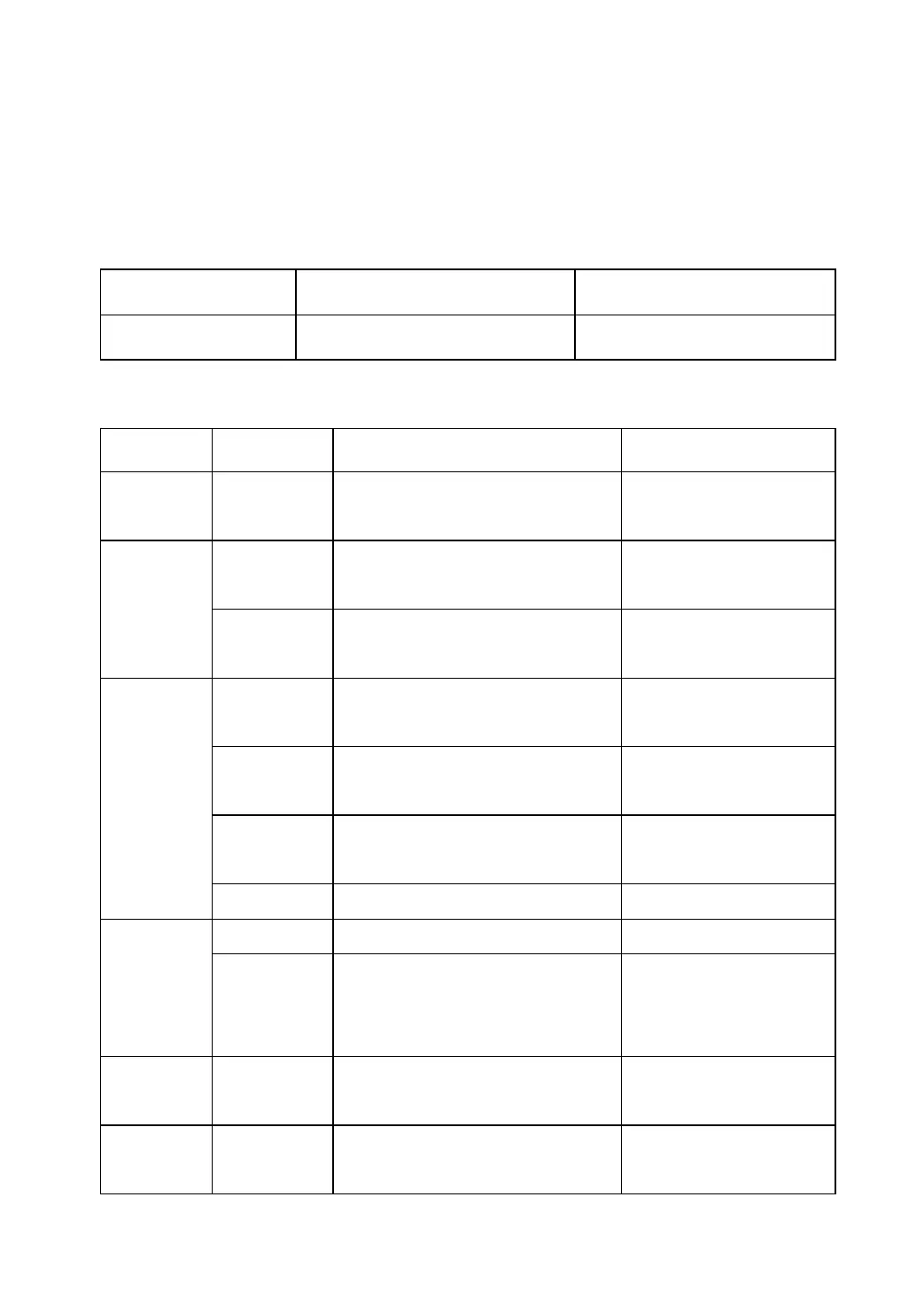

Periodic inspection must be done according to the following list.

Visualization, hearing: grease

leakage, noise and dust

Visualization: high roughness

because of damage, rustiness.

Visualization: looseness,

rustiness and dust

Tighten,

antirust, replace.

Visualization: high roughness

because of damage, rustiness

Visualization: connection,

looseness, insulating treatment.

Visualization: damage of

covering protection.

Insulating resistance higher than

1MΩ (measured with 500V

ohmmeter).

Clean, heat,

treat with varnish

Visualization: damage, discolor,

peeling and rustiness.

Visualization: dirty, dust, and

rustiness.

Clean, antirust

and paint

Loading...

Loading...