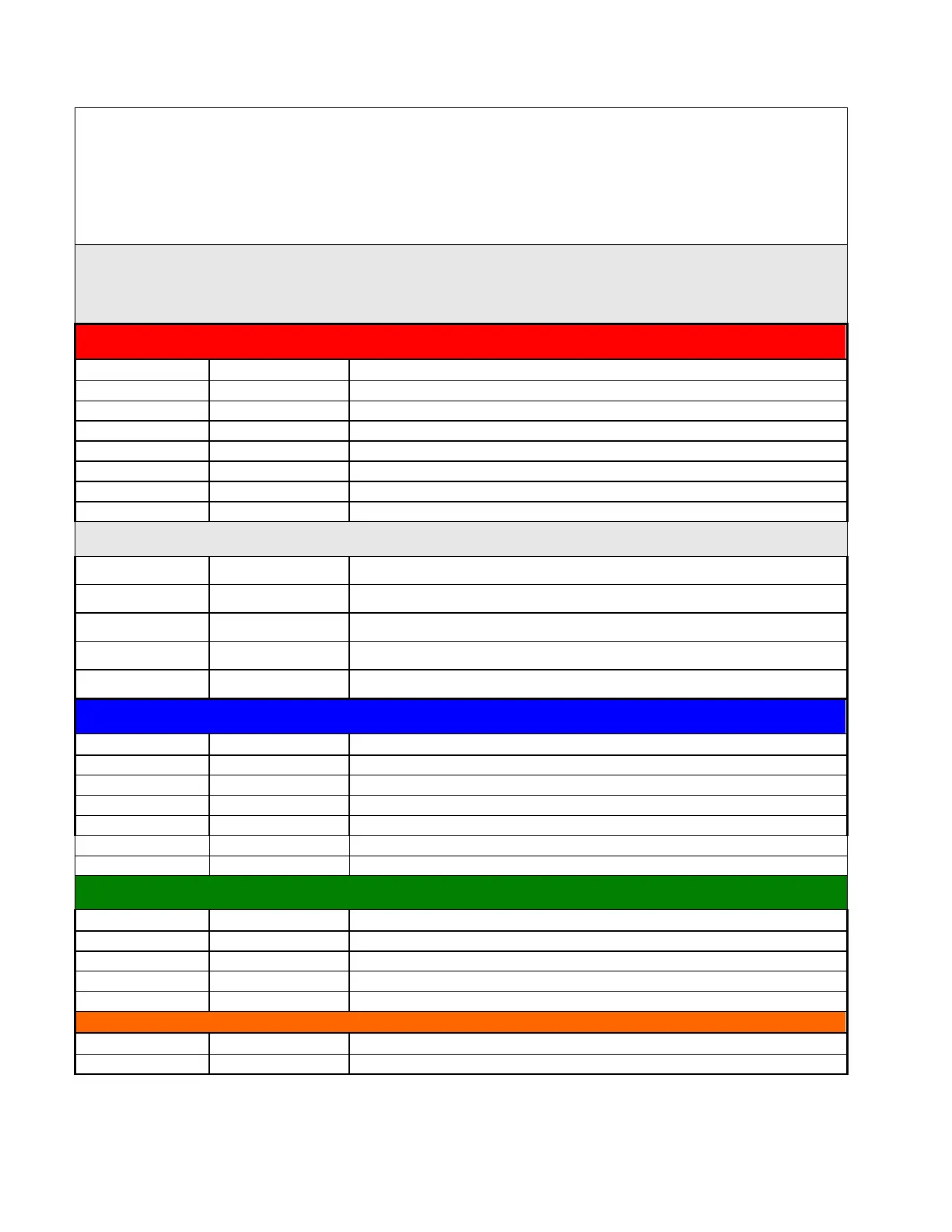

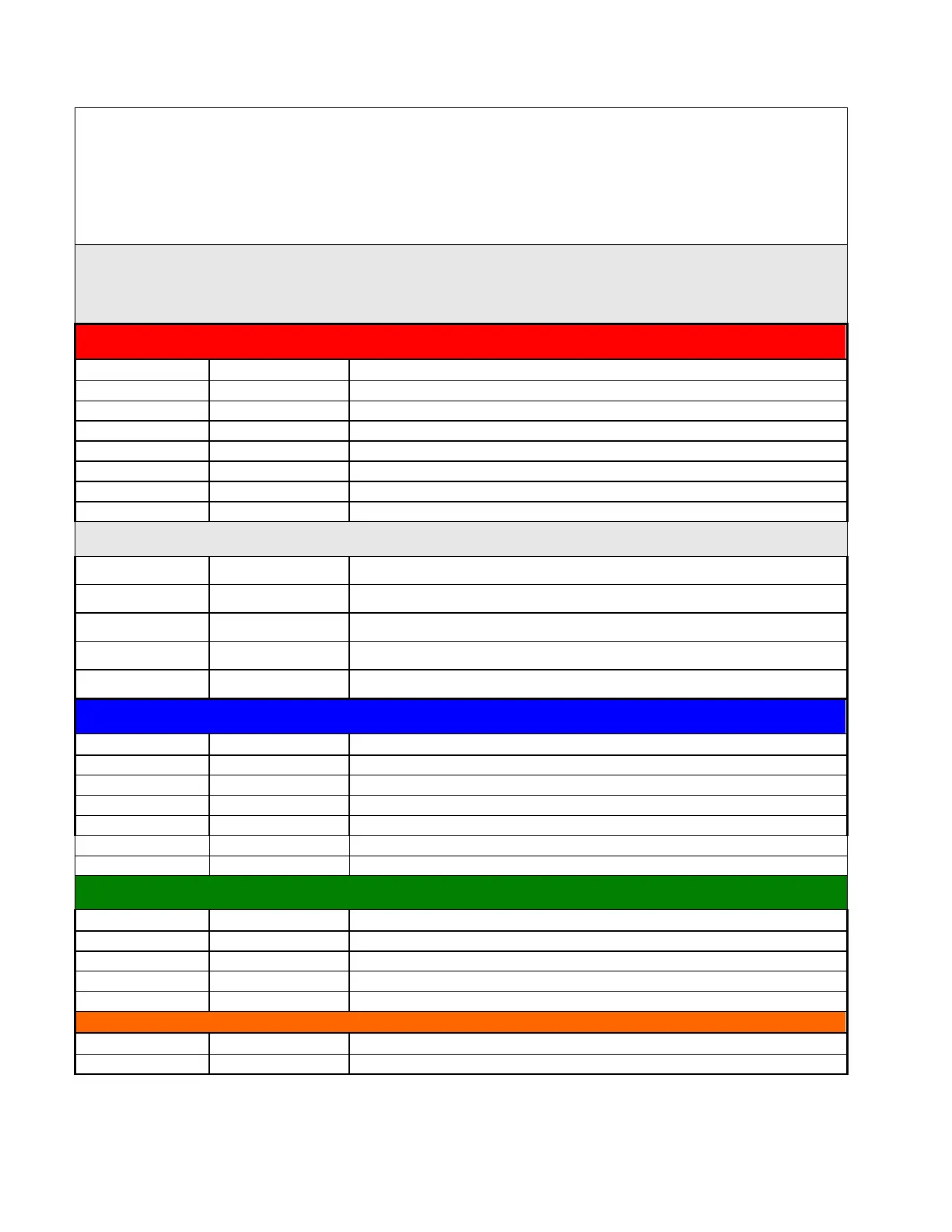

4780 0318

Barber SURF RAKE

®

Model 400

Maintenance & Lubrication Schedule

Every 8 Hours or Every Day:

· Wash Machine After Use

Every 40 Hours or Every Week: Lubricate the following:

Chart Ref. # Barber Part # Description (Quantity)

1 549AS08 8” Roller Assemblies (4)

2 403T Main Shaft Bearings (2)

3 503VV Upper Shaft Bearings (2)

4 527GF-4 Wheel Bearings (2)

5 545NN Cylinder Pins (2)

508RA Caster Arm Sleeve Bearings (2) (Optional Equipment)

530 Finisher Assembly Pins (6) (Optional Equipment)

Every 40 Hours or Every Week Inspect and/or Adjust:

Chart Ref. # Barber Part # Description (Quantity)

6 504FH Replace Broken Tines / Clear Obstructions on tines

7 404AS04 Inspect Conveyor Belt Tension (Both Sides)

8 540G Adjust Conveyor Belt Tension If Needed (Both Sides)

9 527KC Tire Pressure 18 PSI (2)

Every 200 Hours or Every 2 Months:

Chart Ref. # Barber Part # Description (Quantity)

10 522JT1 Spot Lubricate Moldboard Turnbuckle Pins (4)

11 545MM Clean Breather / Filter on Hydraulic Tank

12 545C Change Hydraulic Filter

13 503MMC Inspect and Adjust, if necessary, Main Shaft Drive Chain

14 645HYOIL Check Hydraulic Tank Fluid Level

20 442F Push flap down so it touches chain

Every 500 Hours or Once a Year:

Chart Ref. # Barber Part # Description (Quantity)

15 504G Check / Torque End Bolts on Conveyor to 40psi (40)

16 527GF-4 Adjust / Repack / Replace (if needed) Wheel Bearings

18 645HM Clean Hydraulic Tank Strainer

19 522JT Clean and Grease Moldboard Turnbuckle Assembly (2)

Every 1000 Hours or Once Every 3 Years:

Chart Ref. # Barber Part # Description (Quantity)

17 645HYOIL Change Hydraulic Fluid 10 Gal (ISO-32 Grade or Equivalent)

Loading...

Loading...