12 • Important: Always read and follow operating instructions.

Mounting

This information must be read and followed carefully

to prevent accidents and injuries during mounting.

Attempts to force a bead seat on mismatched

tires and wheels can cause the tire to violently

explode, causing serious personal injury or

death to operator and/or bystanders.

Check tire and wheel carefully before mount-

ing. Make sure the tire bead diameter and

wheel diameter match exactly. Consult the

Tire Guide and/or Rubber Manufacturer’s

Association for approved rim widths for tire

sizes.

Never mount a damaged tire. Never mount a

tire on a rusty or damaged wheel. Damaged

tires and/or wheels may explode.

When in doubt do not mount.

Never mount a tire and wheel handed to you

by anyone without checking both tire and

wheel for damage and to be certain the sizes

match. Do not let untrained persons operate

tire changer and keep bystanders out of ser-

vice area.

Forcing the tire onto the rim can cause bead

damage. If you damage the tire bead during

mounting, STOP!, remove tire and mark it as

damaged. Do not mount a damaged tire.

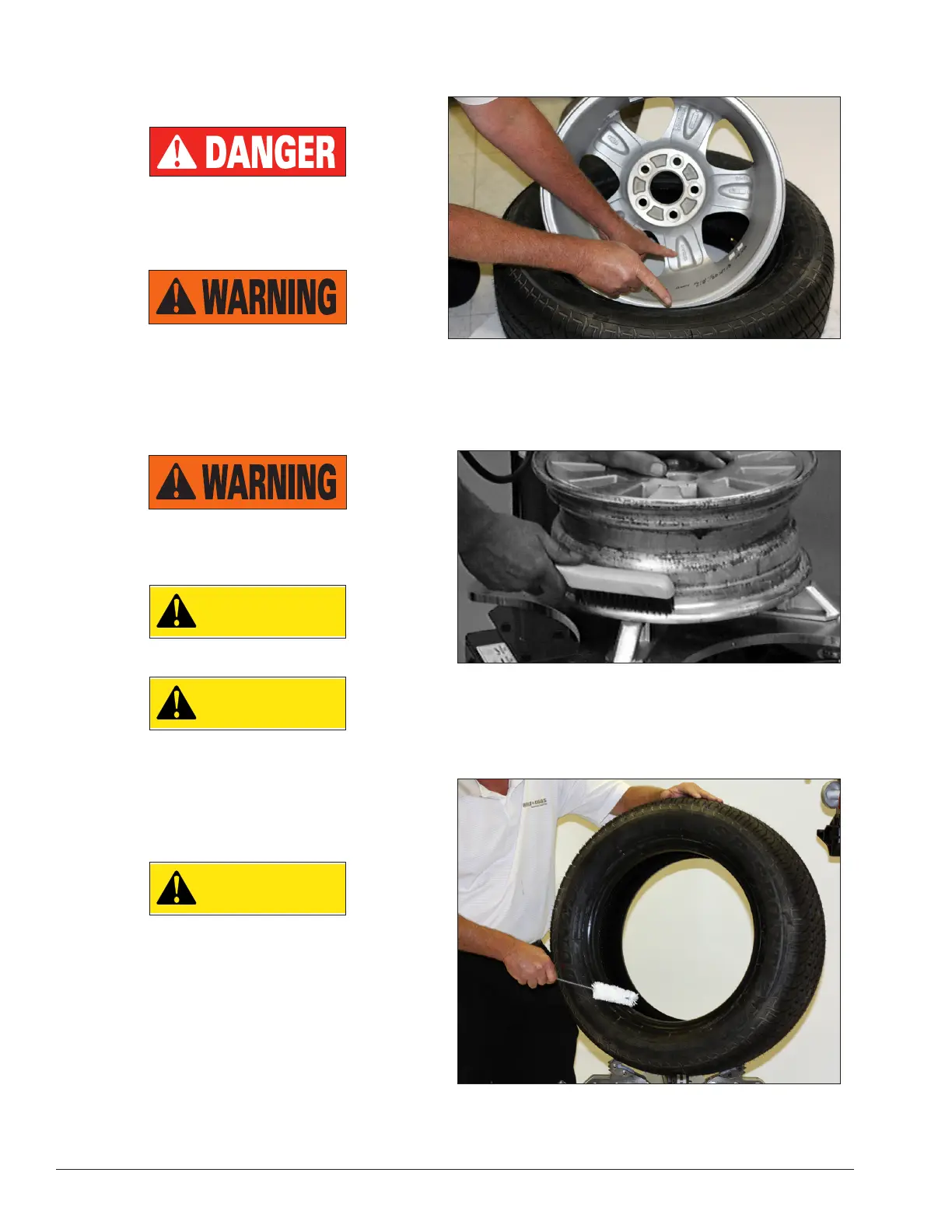

1. Before any mounting, inspect tire for damage and

verify size match between tire and wheel (figure 17).

Figure 17 - Verify Size Match Between Tire and Wheel

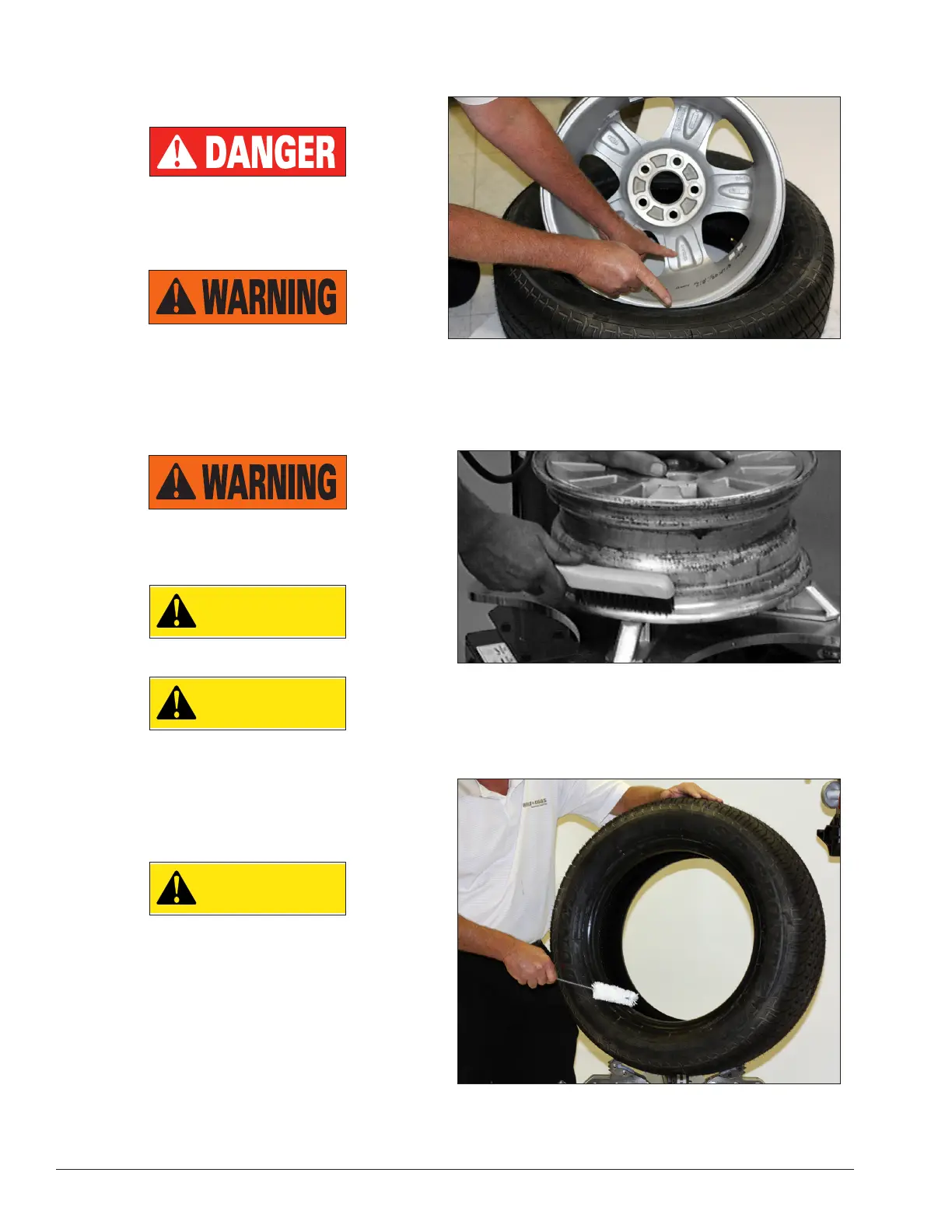

2. Inspect wheel closely for damage. Clean the

wheel and remove any light corrosion or rubber resi-

due (figure 18). Do not attempt to service a heavily

corroded wheel, damaged wheel, or bent wheel.

Figure 18 - Inspect and Clean the Wheel

3. Inspect valve stem and replace if necessary. Next

lubricate tire beads liberally with tire manufacturer’s

approved rubber lubricant (figure 19).

Figure 19 - Lubricate Tire Beads Liberally

Loading...

Loading...