Important: Always read and follow operating instructions. • 25

Pressure Regulator Maintenance

Operating a tire changer with a defective,

improperly adjusted, or by-passed pressure

regulator could cause an operator to acci-

dentally over pressurize a tire, resulting in a

tire explosion with severe injury or death to

the operator or bystanders.

Always be sure that the pressure regulator is

present and is operating properly.

Never inflate tire above manufacturer’s rec-

ommended pressure after bead is seated.

Pressure regulator is set at 60 PSI. Any

required inflation above 60 PSI should be

performed in an inflation chamber/safety

cage or securely mounted on the vehicle if

an inflation chamber is not available. A tire

explosion may cause personal injury or death

to operator or bystanders.

The pressure regulator helps prevent inflation of

standard size or larger tires or tubes beyond 60 PSI to

minimize risk of explosion. This device is for the safety

of the operator and bystanders. Proper operation of

the pressure regulator is essential to safe operation of

the machine.

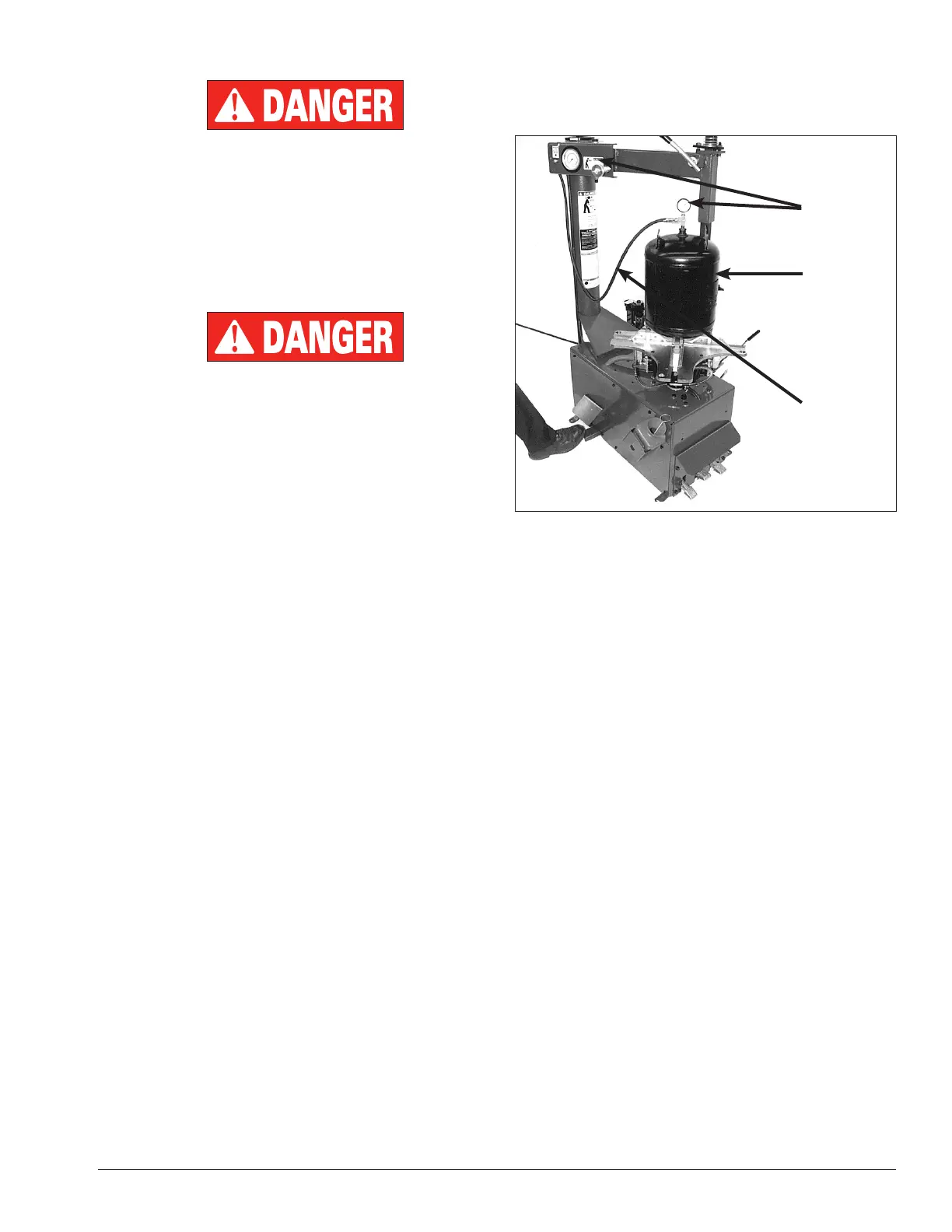

Check operation of the pressure regulator as shown

and described below at least monthly:

1. Remove tires and/or wheels from the machine.

2. Connect the inflation hose to an empty service

tank with a pressure gauge (gauge should read 0).

Use a certified tank with at least 200 PSI pressure

rating.

3. Depress inflation pedal to position 2 to start air-

flow through the hose and into the tank. Maintain a

steady pressure for constant flow.

4. Watch the rising pressure on the tank gauge and

the gauge on the machine. The tank gauge should

rise steadily while inflation pressure is applied. As

tank pressure reaches 60 PSI, the pressure regulator

should stop the airflow automatically. When inflation

pedal is released to position 1, machine gauge and

tank gauge should read 60 PSI ± 5 PSI.

5. Replace pressure regulator if it fails to shut air

supply o at 60 PSI, or if it malfunctions in any other

way. Do not operate machine with a faulty pressure

regulator.

Figure 37 – Pressure Regulator Maintenance

Oil Injector Maintenance

The oil injector typically requires annual service. The

oil level in the oil reservoir tank should be checked

regularly.

Add oil to oil reservoir tank when fluid level is a quar-

ter full or below. Remove cap from the oil reservoir

tank and add Chevron Regal

®

R & O 32 oil to full line

(air tool oil is an acceptable substitute). Replace cap

and clean up any spilled oil.

Important: An air lock will form if the hose between

the reservoir and injector is ever empty of oil. In this

case, after filling the reservoir tank, the line must be

bled of air at the injector connection as follows:

1. Disconnect all power sources, both air and elec-

tricity inputs. Allow any stored air in the reservoir to

escape by depressing the inflate pedal.

2. Remove the side panel and locate the oil injector.

3. Prime the oil injector. Loosen bleeder plug until oil

drips from screw and all air is relieved from the oil line

hose. Retighten the bleeder screw.

4. Reconnect air/electric sources and cycle the

clamp control pedal a few times checking for oil and

air leaks.

5. Test the machine for full function before returning

the machine to operation.

6. Monitor oil consumption to ensure oil is being used

in system.

Watch

Pressure on

Both Gauges

200 PSI Tank

with Gauge

Tire Changer

Inflation

Hose

Connected to

Tank

Loading...

Loading...