18 • Important: Always read and follow operating instructions.

Stages of Ination on a

Conventional Tire and Rim

Review these descriptions and diagrams carefully. Refer to them as

necessary during bead sealing, bead seating, and inflation to verify that

you are proceeding properly and safely.

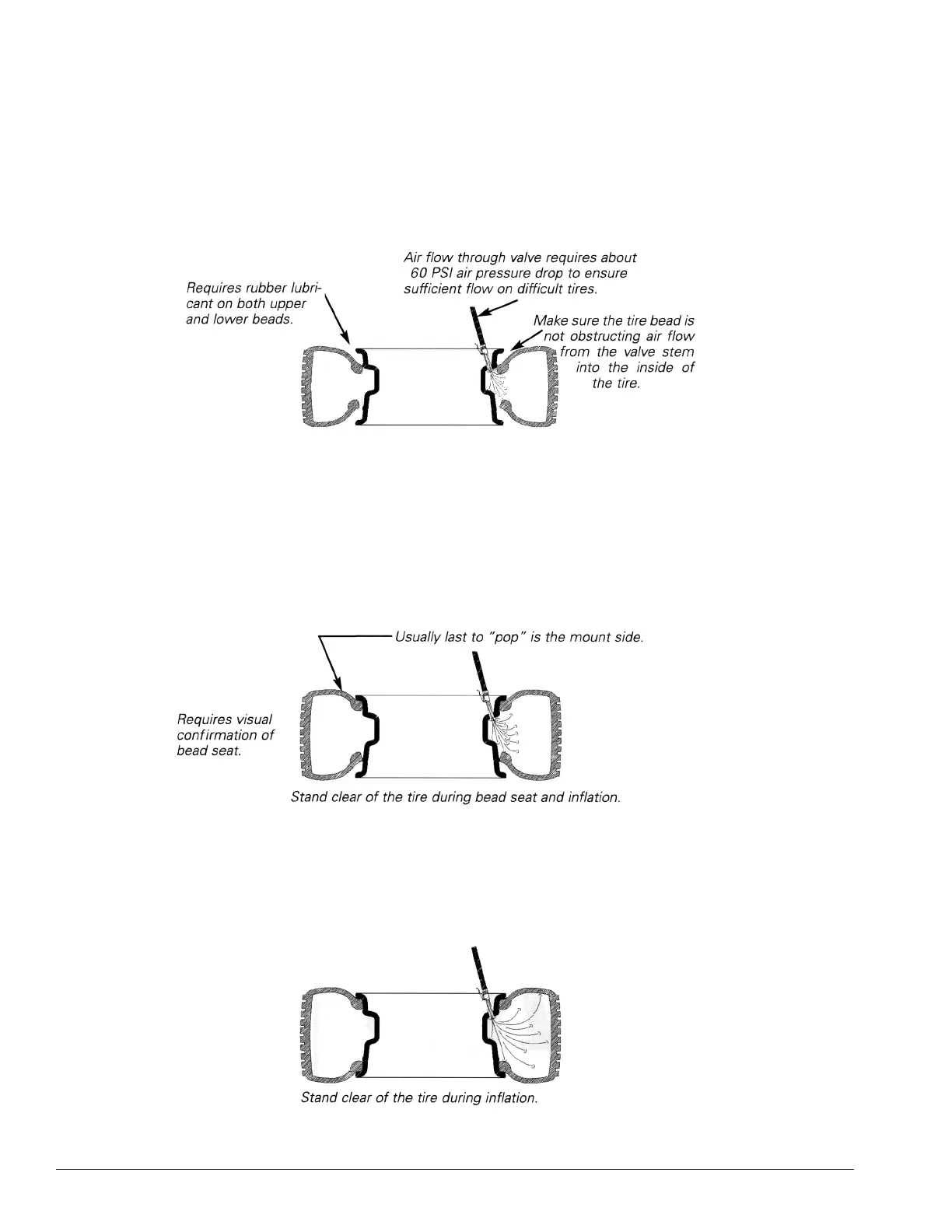

Bead Sealing

Bead sealing is the process of capturing air pressure between the tire

and the rim. The tire will usually contain about 1/2 to 2 PSI at initial bead

seal.

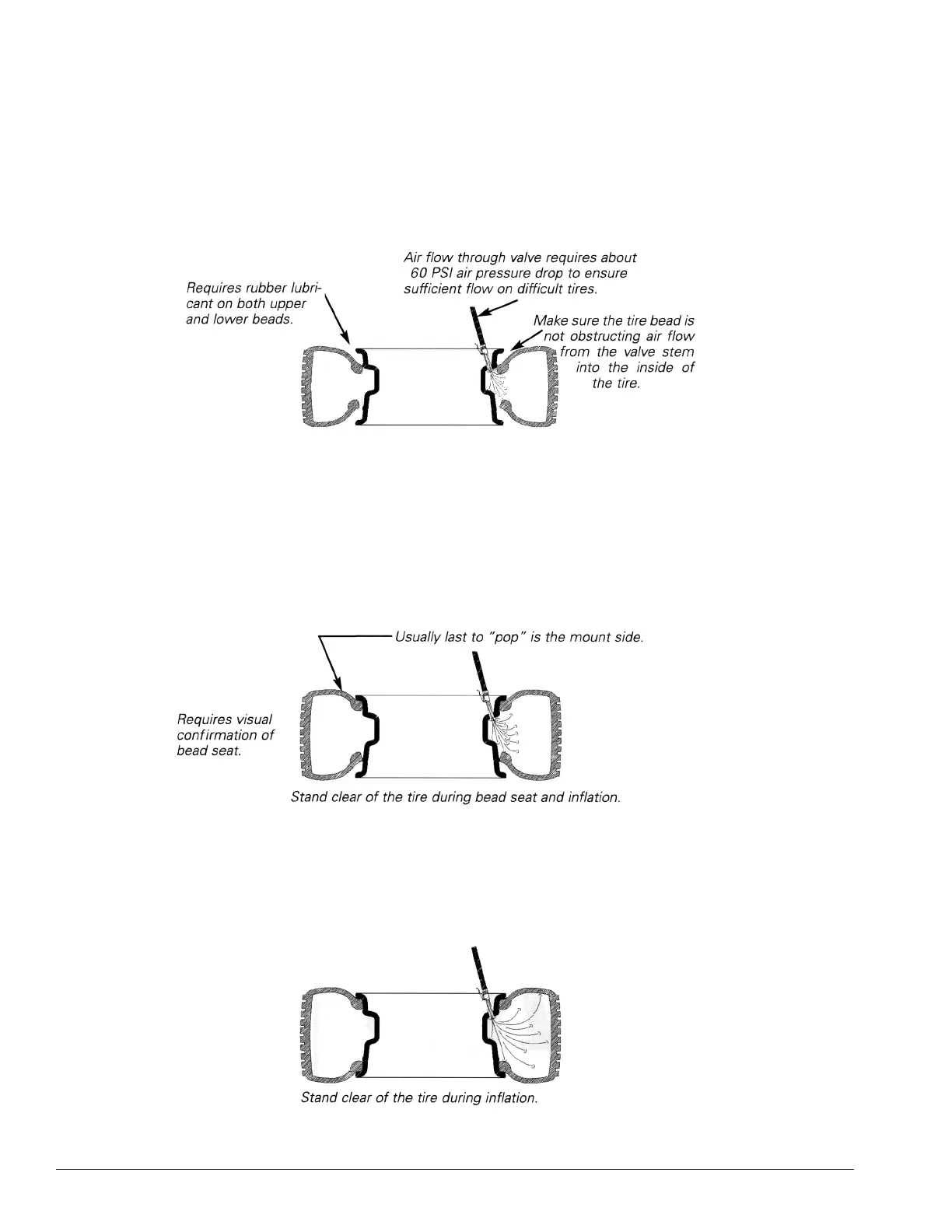

Bead Seating

Bead seating usually occurs on the long tapered side of the wheel first

and the shorter side last. Bead seating will usually require at least 7 PSI

in the tire. 40 PSI is the maximum safe pressure at this stage regardless

of tire operating pressure.

Most European import cars and many aftermarket alloy wheels are

very tight and can be dicult to bead seat. Also note that asymmetrical

hump and run-flat tires are extremely dicult to bead seat. Follow tire

manufacturer’s recommended procedure for bead seating.

Inflation

After the beads are seated, the tire is ready to be inflated. Do not

inflate the tire above the manufacturer’s recommended pressure as

stamped on the tire sidewall. The typical inflation pressure for automo-

bile tires is between 24 and 45 PSI. Light truck inflation pressure typi-

cally covers a wider range.

Loading...

Loading...