4 • Important: Always read and follow operating instructions.

Set Up Instructions

Proper unit installation is necessary for safe

use and ecient operation. Proper instal-

lation also helps protect the unit from dam-

age and makes service easier. Always place

safety poster and instructions near the unit.

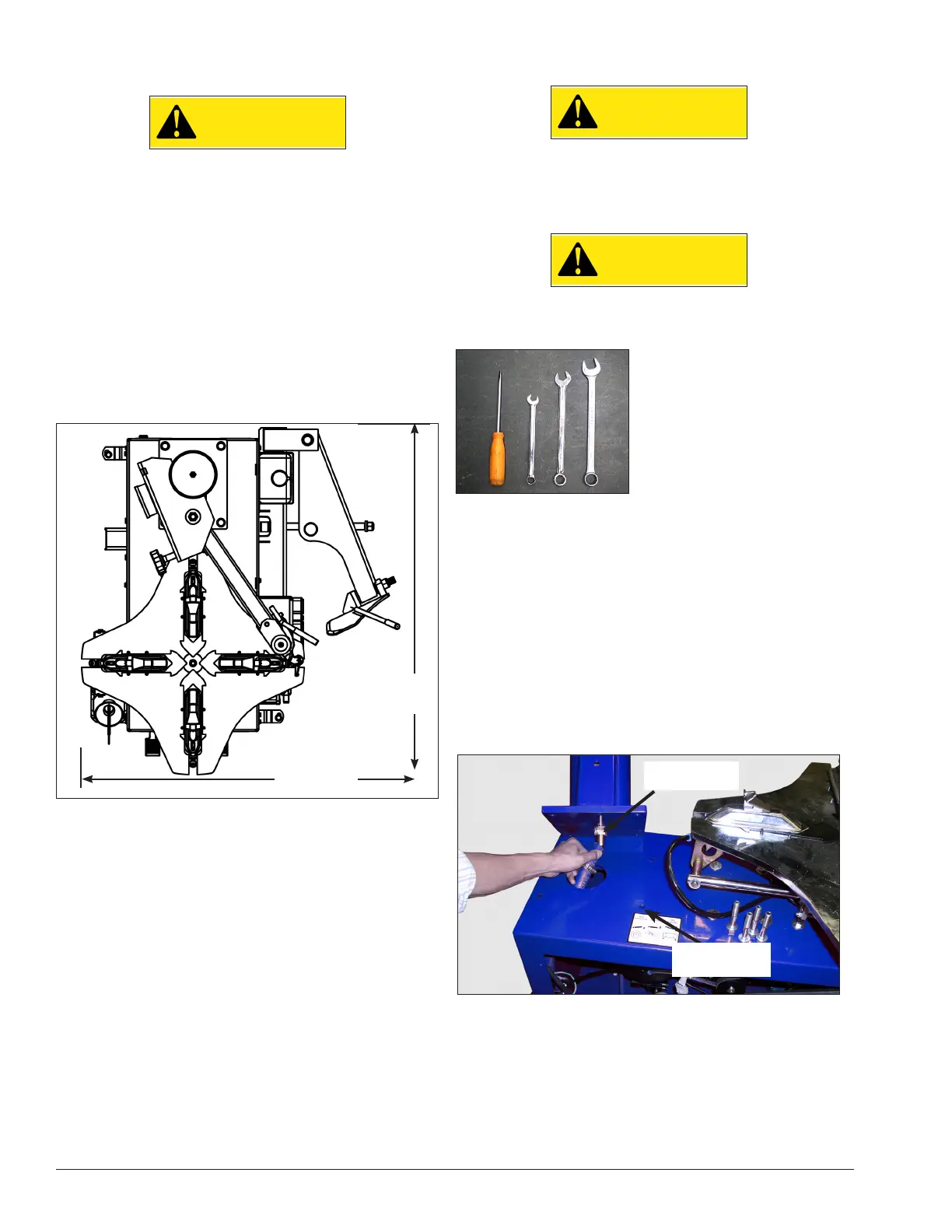

Location

Select a location using the drawings below. The area

should provide the operator with enough space to use

the equipment in a safe manner. The area selected

should be well lit, easy to clean and should be away

from oil, grease, brake lathe chips, etc. Avoid areas

where bystanders and customers may be present.

Workspace Requirements

Figure 1 –Work Space Requirements

Tower Installation

STAY CLEAR OF MOVING PARTS when recon-

necting the unit to the air supply. The position

of control valves may have changed during

the servicing of the machine.

Be careful of pinch point at swing arm spring.

Tools Required:

Screw Driver

14 mm Open-ended Wrench

19 mm Open-ended Wrench

24 mm Open-ended Wrench

1. Carefully remove carton and packaging from unit.

2. Using a 14 mm wrench, remove shipping bolts

holding tower, swing arm and chassis to the pallet.

3. Using a 19 mm wrench, remove the four bolts and

washers from the chassis; reserving the bolts and

washers.

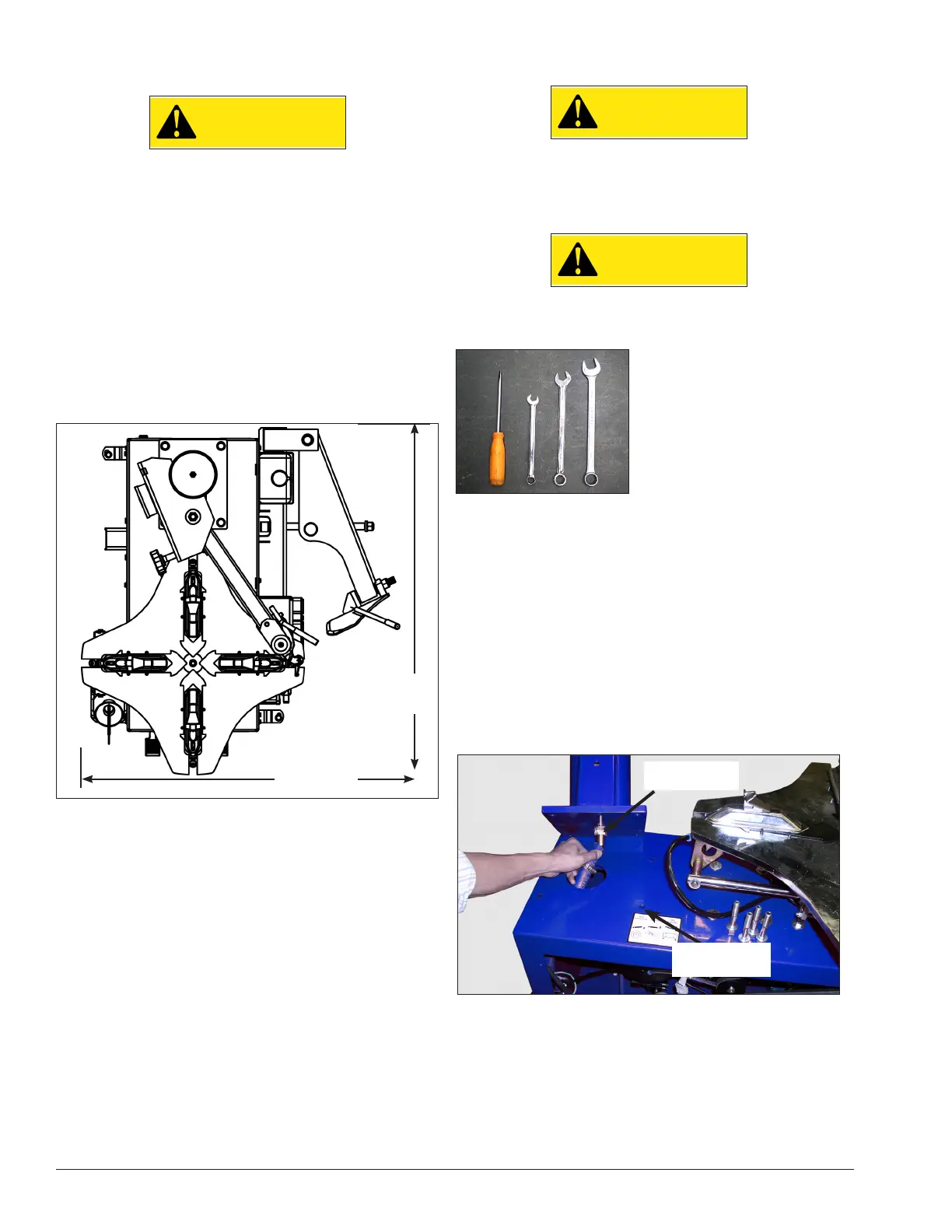

4. With the aid of a helper holding the tower, connect

hose from chassis to tower barb fitting (figure 2). Posi-

tion and tighten hose clamp.

5. Use reserved bolts and washers to attach tower to

chassis (figure 2). Torque to 15 - 20 ft. lbs.

Figure 2 - Assemble tower onto chassis.

50"

(1270 mm)

41.5"

(1054 mm)

Use Reserved

Bolts & Washers

Connect Hose To

Tower Fitting

Loading...

Loading...