Important: Always read and follow operating instructions. • 15

Use of bead sealing jets without a tire in place

can cause dirt and debris to be blown into the

air with enough force to injure operator and/

or bystander. Do not use the bead sealing

control position to inflate a tire.

This unit is equipped with a pressure regulator

to assist the operator with proper tire inflation.

The pressure regulator will keep most car and

light truck tires from inflating beyond 60 PSI

(smaller tires may reach higher pressures). It is the

operator’s responsibility to follow all instructions

and to control inflation pressure as specified in

these instructions. Check the function of the pres-

sure regulator regularly and maintain it according

to the instructions provided in this manual for safe

and proper operation. Do not tamper with or

attempt to adjust the pressure regulator. Tires

requiring inflation beyond 60 PSI should be

inflated in a safety cage.

Bead Sealing

1. Remove the valve core from the valve stem to allow

more air flow into the tire to assist with bead seal.

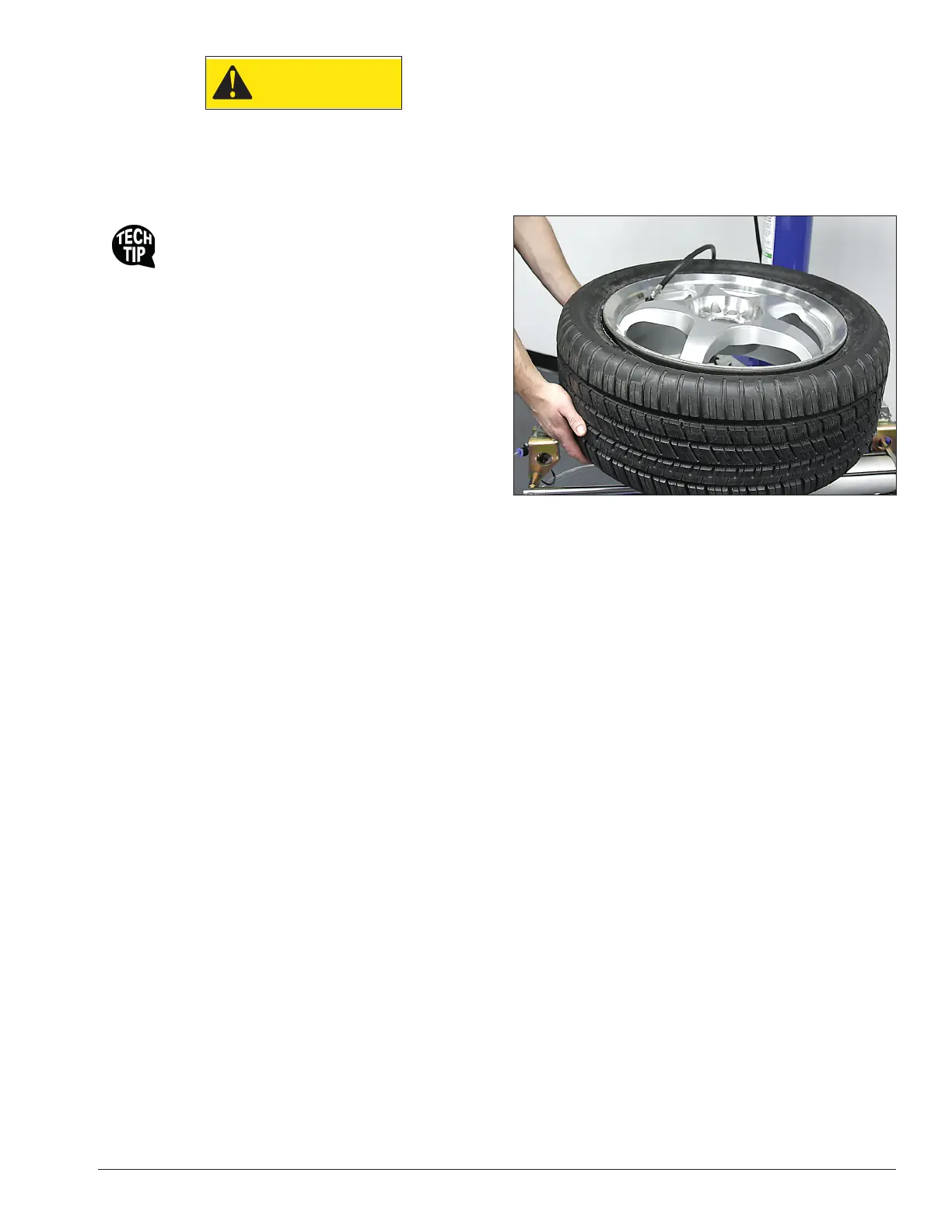

2. Position valve stem in front of operator and con-

nect the inflation hose with the clip-on chuck. Hold

tire up against upper edge of the wheel. Be sure tire’s

top bead does not cover the bottom of the valve stem

(figure 22).

Figure 22 - Lift Tire Upwards for Bead Sealing

3. Depress inflation pedal to position 2 and hold

about one second to begin air flow through tire valve,

then depress pedal to position 3 and hold briefly —

less than one full second. The blast of air from the jets

will expand tire and seal the beads.

4. Release the inflation pedal and allow it to return

to position 1. Verify that both beads are completely

sealed to the wheel. Repeat these steps if beads have

not sealed. It may be necessary to wait a few seconds

for the air storage tank pressure to recover before

attempting again.

5. After bead seal is achieved, remove the clip-on

chuck and reinstall the valve core. Reattach the clip-

on chuck after core is installed.

Loading...

Loading...