36

o If the cooker has been converted for use with LPG, then it should

be connected to the gas supply using an appropriate bayonet

type hose. The hose MUST be suitable for use with LPG gas,

these are identifiable by a red band or stripe.

o A hose length of 0.9m to 1.25m is recommended. The length of

hose chosen should be such that when the cooker is in situ, the

hose does not touch the floor.

o Care should be taken to ensure that the temperature rise of

areas at the rear of the cooker that are likely to come in contact

with the flexible hose do not exceed 70°C.

o IMPORTANT: On completion carry out a gas tightness test.

Gas adjustment (Conversion to LPG and gas adjustment)

IMPORTANT: Your appliance must be disconnected from the

electric and gas supply before completing this process.

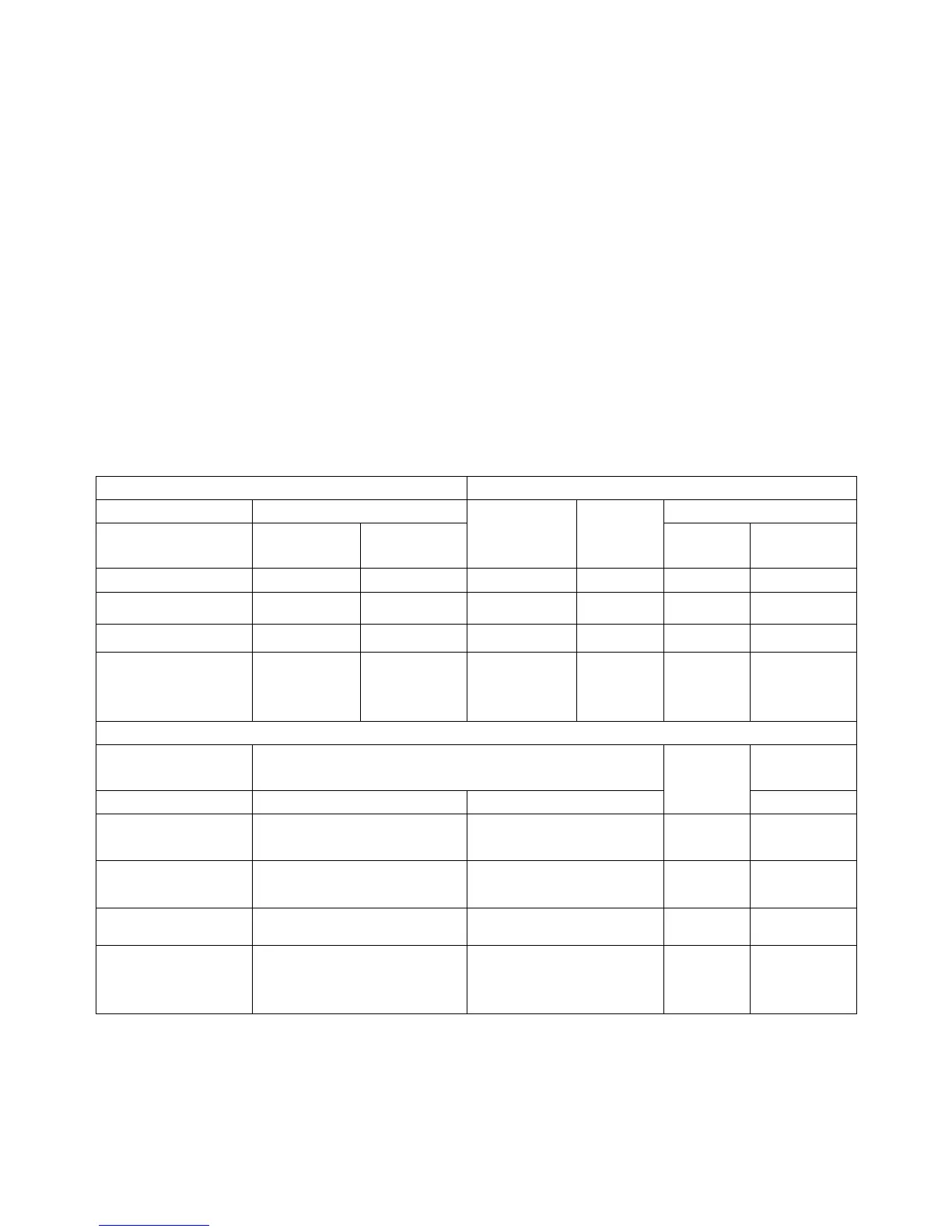

Liquid gas

Burner Thermal power Capacity (g/h)

Nominal Reduced

By-pass

1/100

(mm)

Nozzle

1/100

(mm)

G30 G31

Main oven 1.80 0.50 36 65 (M)

131 129

Grill 2.90 2.00 90 78 (X) 211 207

Maximum 4.70 342 336

Supply

pressure

Nominal

Minimal

Maximum

28-30

20

35

37

25

45

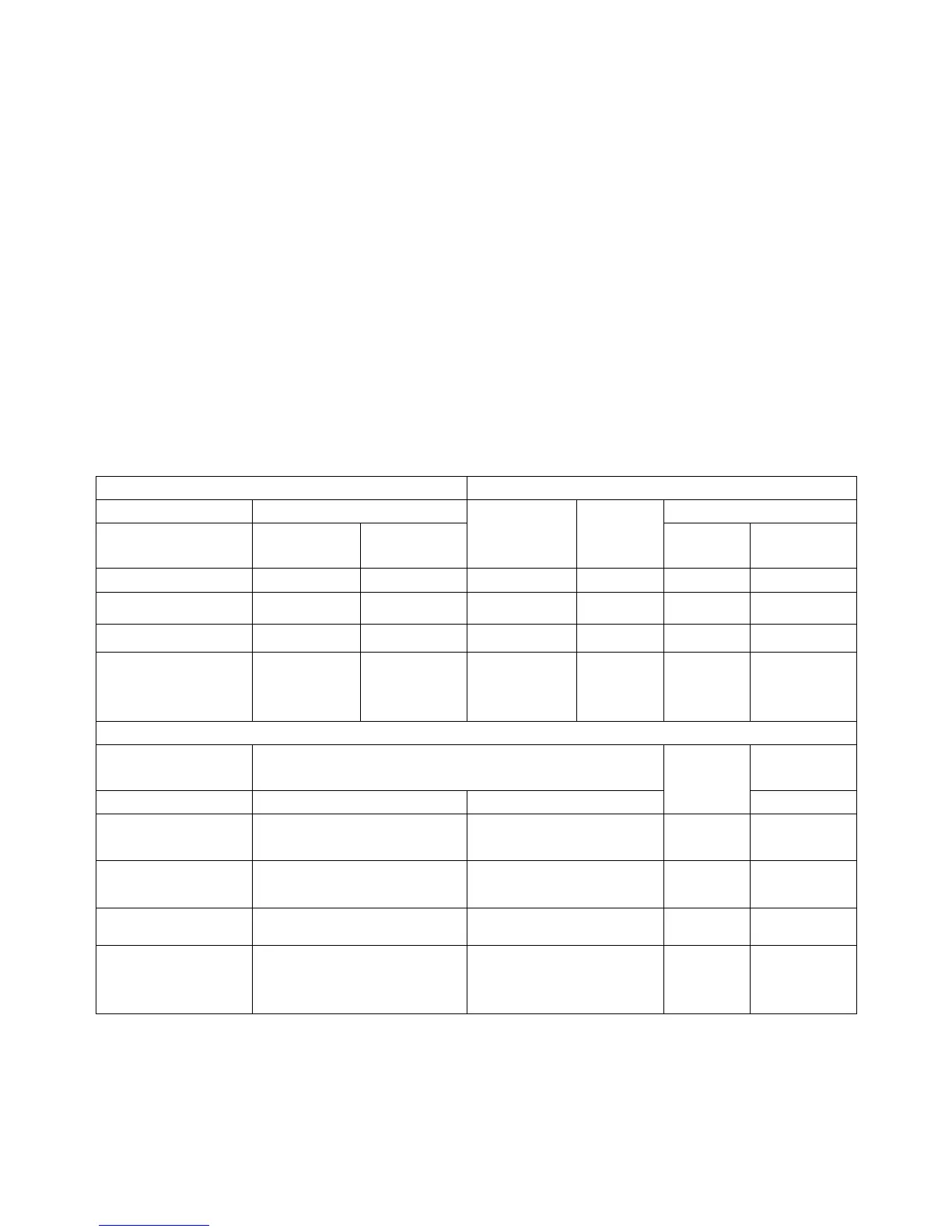

Natural gas

Burner Thermal power Capacity

(LH)

Nominal Reduced

Nozzle

1/100

(mm)

G20

Main oven 1.80 0.50 95

(F2)

172

Grill 2.90 2.00 122

(F2)

276

Maximum 4.70 448

Supply

pressure

Nominal

Minimum

Maximum

20

17

25

IMPORTANT: The letters shown in the nozzle columns indicate the

type of hole that is drilled inside of the gas jet.

Loading...

Loading...