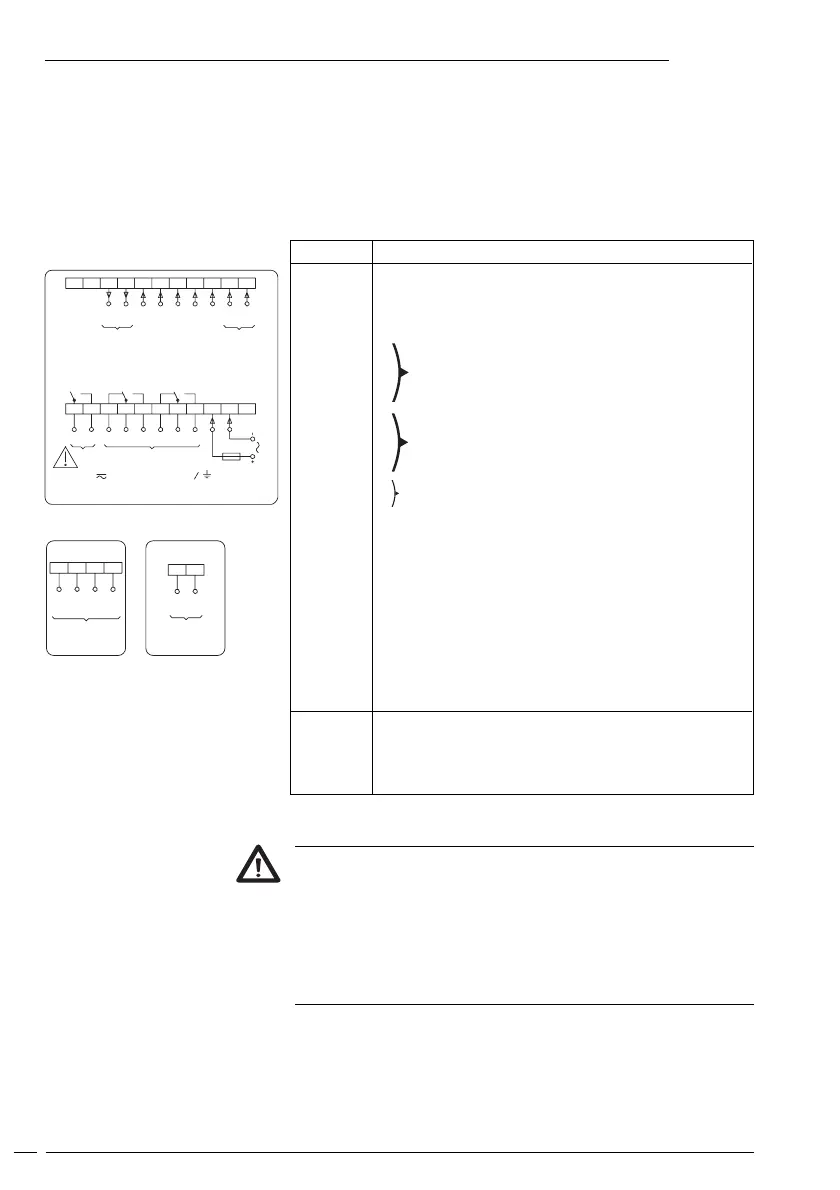

6

NE215

Counter connect

GND

RxD

TxD

RS232

26 25 24 23

22 21

RS485

T, R +

T, R -

1 Relay contact output P1

1 Relay contact output B1

1 Relay contact output P2

3 Counter connect

This chapter will explain how the contacts are assigned.

Under chapters 3.1 to 3.5 you will find actual tips and technical data

for the various connections.

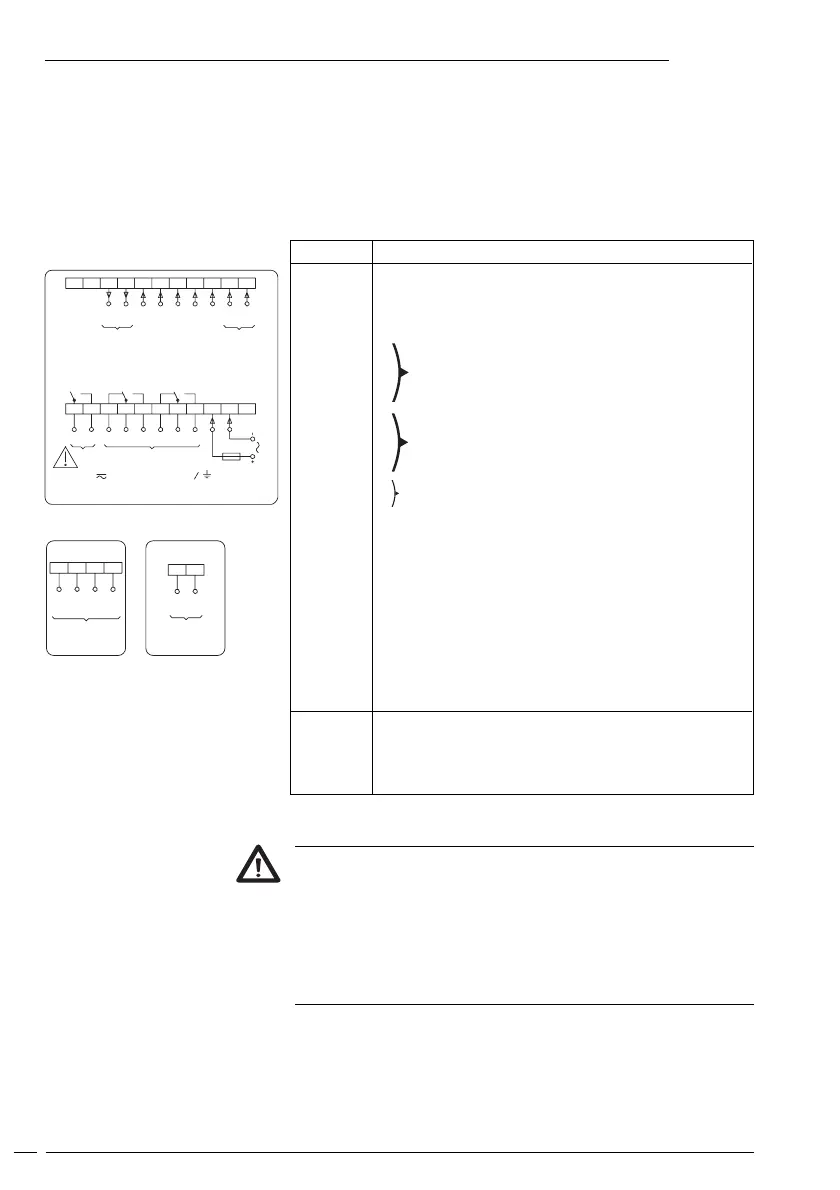

The electrical inputs and outputs are assigned to two 12-pole plug-in

screw terminals, coded to prevent reversed polarity.

Assignment

Contact Function

1 Not assigned

2 Supply voltage

3 Supply voltage

4

5

6

7

8

9

10

11

12 Signal input, track A

13 Signal input, track B

14 Reset XP

15 Time meter

16 Signal input, track B1

17 Reset B1

18 Coding input for input logic

19 Encoder supply 0 Volt

20 Encoder supply +24 Volt

21 Option RS485 T,R-

22 Option RS485 T,R+

23 Option RS232 TXD

24 -

25 Option RS232 RXD

26 Option RS232 GND

Litz contact only by means of connector sleeves with insulating

enclosures for reasons of shock protection according to VDE 0411

part 100. Do not otherwise assign contacts that have been left

unassigned ex factory. We recommend to screen all encoder

terminal leads and to ground the shield on one side. Shields on

both sides are recommended in case of RF interference or in case

of equipotential bonding over long distances. The encoder leads

should not be in the same phase winding as the MAINS supply and

the output contact leads.

max. 250 V Terminal - Terminal - Terminal

Output

B1 P2 P1

BA

Count

+24V 0V

Sensor

supply

NPN Br. 18-20

PNP Br. 18-19

B1 reset

B1 counter

(Scaling on)*

XP reset

Supply

22 21 20 19 18 17 16 15 14 13 12

11 10 9 8 7 6 5 4 3 2 1

h counter

* Models with scaling

Loading...

Loading...