Commissioning/application notes

EK110x, EK15xx64 Version: 3.6

3. Grinding and polishing

Any fibers protruding more than 1.5mm from the connector should be shortened with a cutter knife or a pair

of scissors.

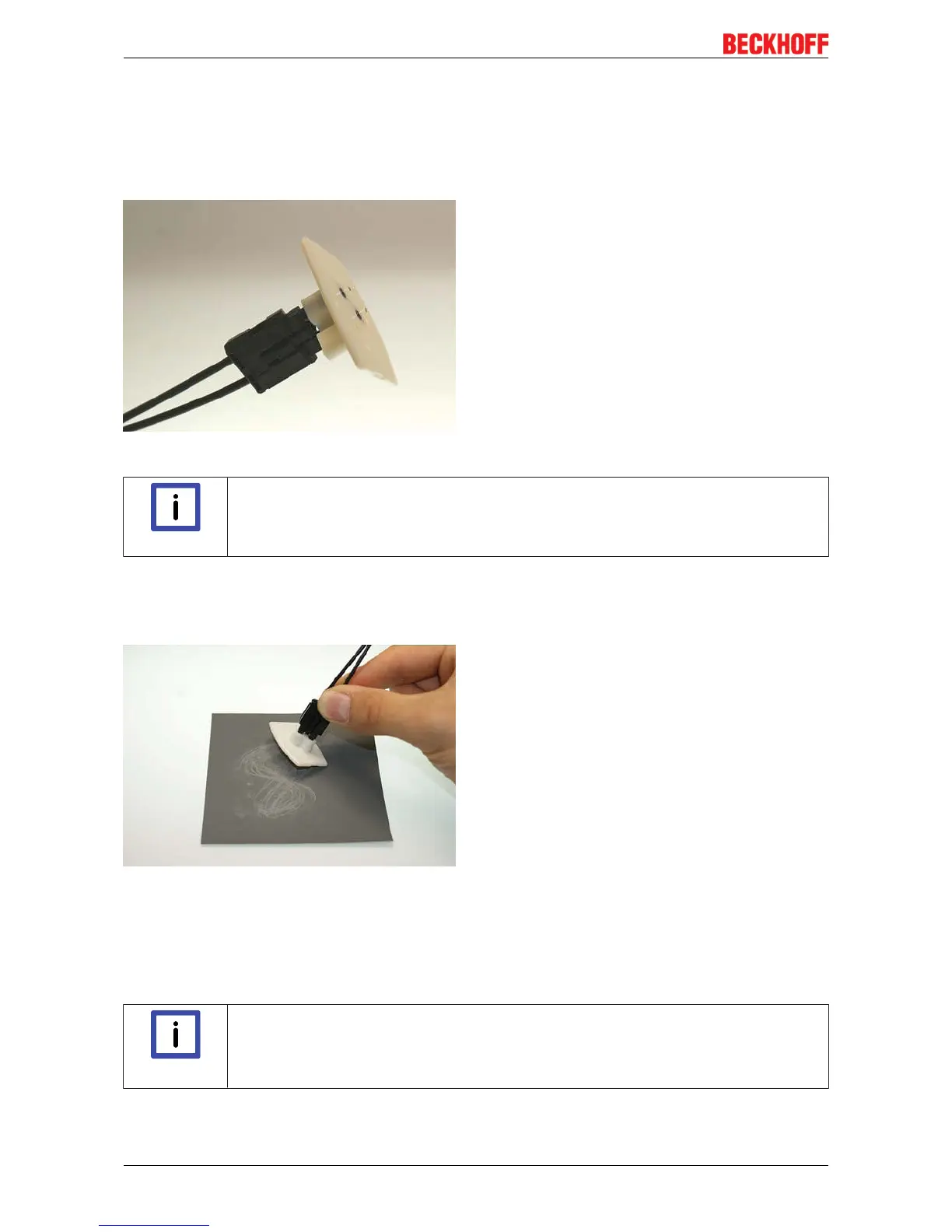

Now push the connector fully into the sanding gauge, so that the ends to be polished protrude from the lower

side. The sanding gauge is suitable for polishing one or two simplex connectors or a duplex connector.

Fig.47: Sanding gauge with protruding fiber ends

Note

Wear indicator

The wear indicator of the sanding gauge consists of four points on the underside. The

sanding gauge should be replaced when one of these points is no longer visible.

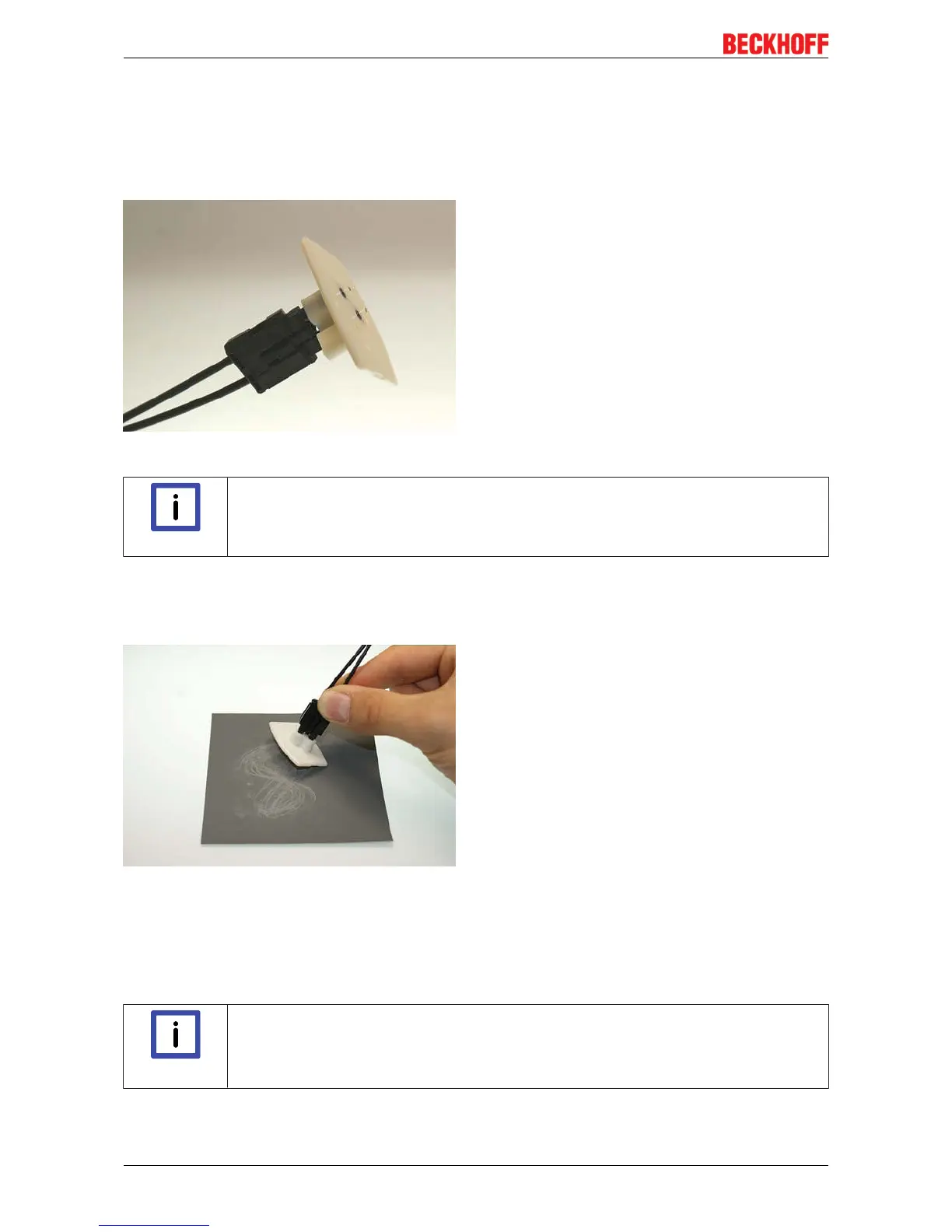

Now press the sanding gauge onto the abrasive paper with uniform pressure and as perpendicular as

possible. In order to achieve a uniform result, use the abrasive paper in the form of a figure of 8, until the

fibers are flush with the sanding gauge. Then clean the sanding gauge and the connector from below with a

soft, dry cloth.

Fig.48: Polishing in the form of a figure of 8

4. Fine polishing

Now use the pink polishing sheet for fine polishing in the same manner. Apply the connector with the

sanding gauge to the matt side of the polishing sheet with slight pressure and polish in the form of a figure of

8 up to 25 times. After the procedure the fiber end should be flat, smooth and clean.

Note

Improving the transfer performance by fine polishing

Fine polishing with a polishing sheet can improve the transfer performance between the

transmitter and the receiver or in the cable joint by up to 0.5 dB compared with to treatment

with abrasive paper alone. For short transfer distances the polishing step can be omitted.

Loading...

Loading...