PLC API

TS505536 Version: 1.3

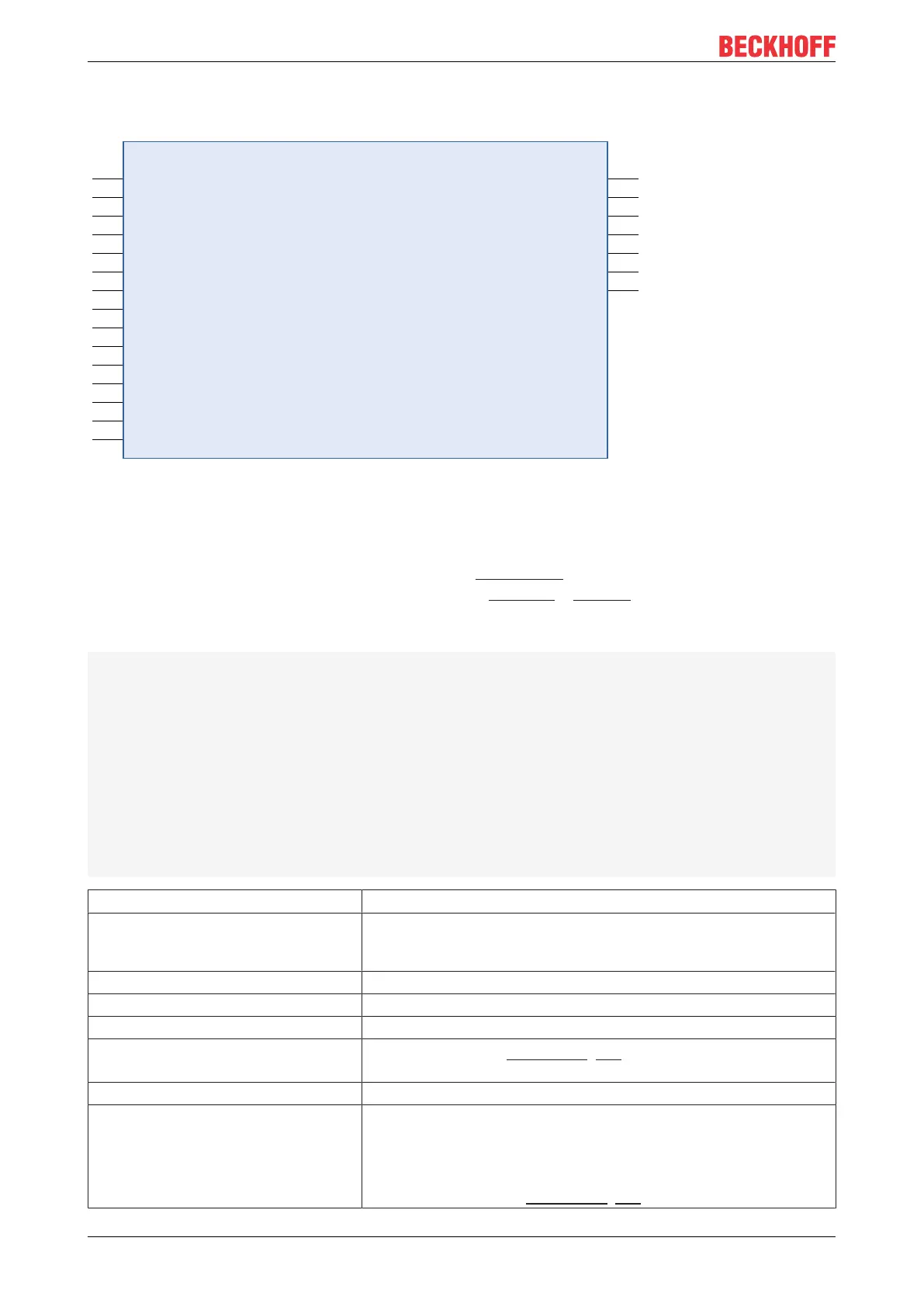

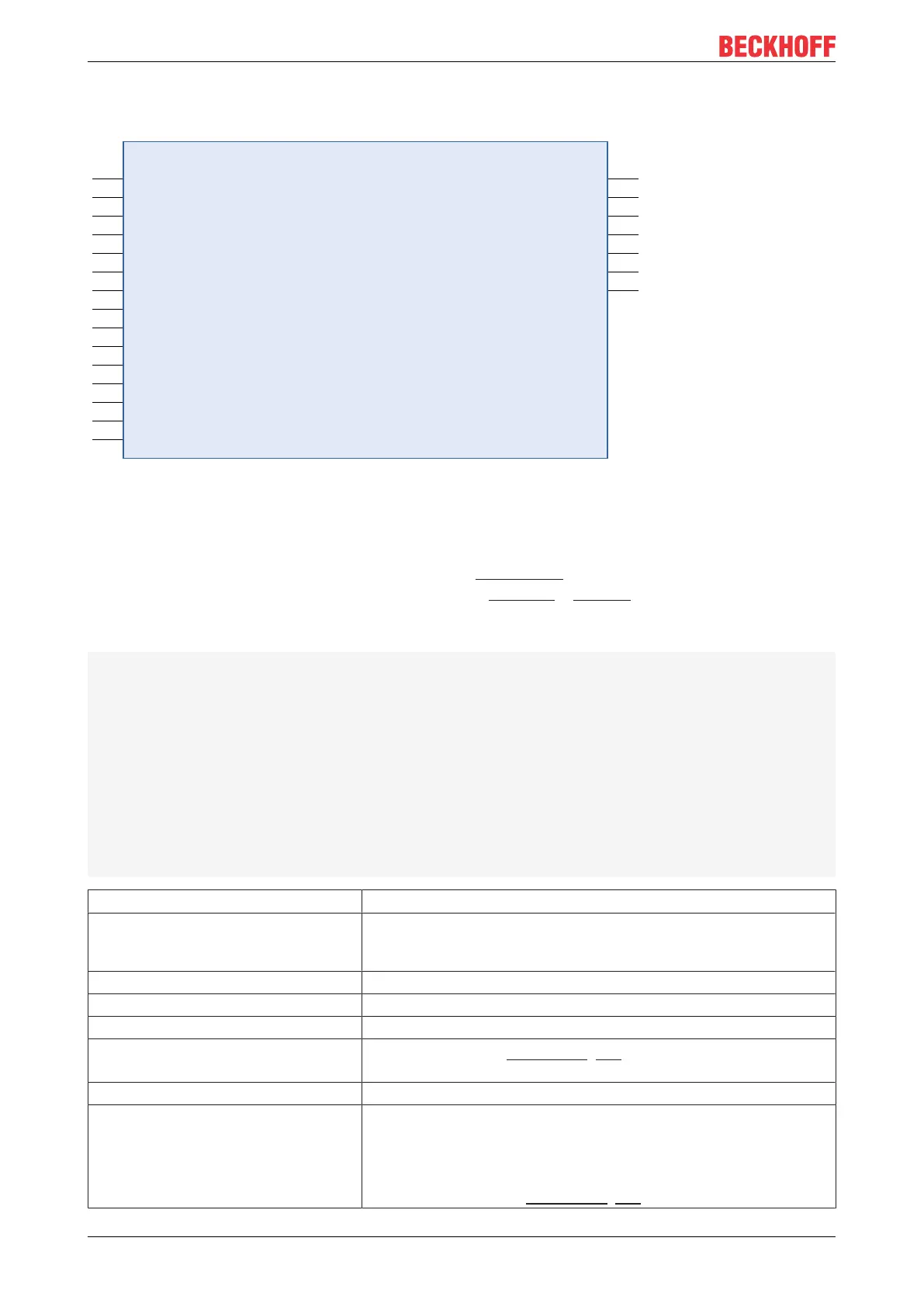

12.1.2 MC_GearInPos

MC_GearInPos

ExecuteBOOL

RatioNumeratorLREAL

RatioDenominatorUINT

MasterSyncPositionLREAL

SlaveSyncPositionLREAL

SyncModeST_SyncMode

MasterStartDistanceLREAL

VelocityLREAL

AccelerationLREAL

DecelerationLREAL

JerkLREAL

BufferModeMC_BufferMode

OptionsST_GearInPosOptions

↔

MasterReference To AXIS_REF

↔

SlaveReference To AXIS_REF

BOOLStartSync

BOOLInSync

BOOLBusy

BOOLActive

BOOLCommandAborted

BOOLError

UDINTErrorID

The function block MC_GearInPos synchronizes a slave axis precisely with a master axis (flying saw). The

synchronization velocity is achieved exactly at the synchronous position of the master and slave.

The master axis must already be moving, otherwise synchronization is not possible.

The slave axis can be uncoupled with the function block MC_GearOut. If the slave is decoupled while it is

moving, then it retains its velocity and can be halted using MC_Stop or MC_Halt.

Inputs

VAR_INPUT

Execute:BOOL;

RatioNumerator:LREAL;

RatioDenominator:UINT;

MasterSyncPosition:LREAL;

SlaveSyncPosition:LREAL;

SyncMode:ST_SyncMode;

MasterStartDistance:LREAL;

Velocity:LREAL;

Acceleration:LREAL;

Deceleration:LREAL;

Jerk:LREAL;

BufferMode:MC_BufferMode;

Options:ST_GearInPosOptions;

END_VAR

Execute The command is executed with a rising edge at Execute input.

RatioNumerator Gear ratio numerator.

Alternatively, the gear ratio can be specified as a floating point

value, if the denominator is 1.

RatioDenominator Gear ratio denominator

MasterSyncPosition The master's synchronous position

SlaveSyncPosition The slave's synchronous position

SyncMode

In the data structure SyncMode [}41] boundary conditions for the

synchronization process are specified via individual flags.

MasterStartDistance Currently not implemented

Velocity Maximum slave velocity in the synchronization phase. If a velocity is

not specified, the maximum velocity of the axis from the System

Manager data is used.

The velocity given here is only checked if this checking is

activated through the SyncMode [}41] variable.

Loading...

Loading...