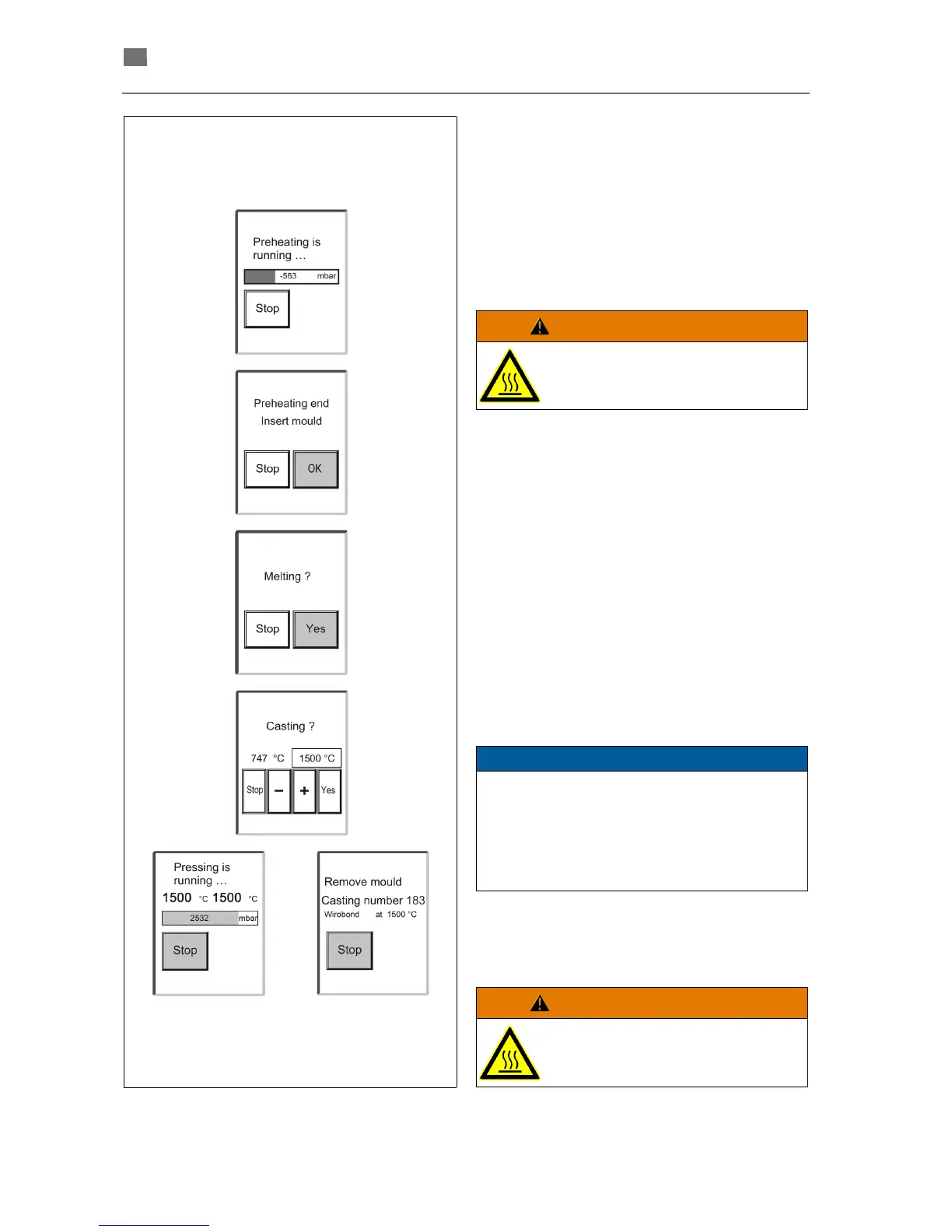

The chamber is evacuated during preheating.

The preheating may last for up to 60 seconds. A

signal sounds at the end.

10. To prevent the alloy from cooling down unnec-

essarily: Get the moulds first, then press „OK“!

11. The preheating temperature and partial vac-

uum are maintained until then.

12. The next display is shown when the mould

door is closed.

13. The melting must now be confirmed with

„Yes“!

The rest of the processing runs automatically

although manual intervention is also possible

(see note).

The actual temperature and casting temperature

are displayed.

(Only actual temperatures above 700 °C.)

Casting takes place automatically after the casting

temperature is reached. For crucible inserts, only

after the "holding time" has expired so the melt is

completely heated (exception: Program 131).

The casting is carried out with overpressure.

Finally, the casting number, spilt alloy and casting

temperature are displayed.

If desired, manual intervention is possible.

• As soon as the actual temperature is 50 °C

below the casting temperature, the casting can

be triggered by pressing the "Yes" key.

• The casting temperature can be changed by

pressing the "-" and "+" keys.

Loading...

Loading...