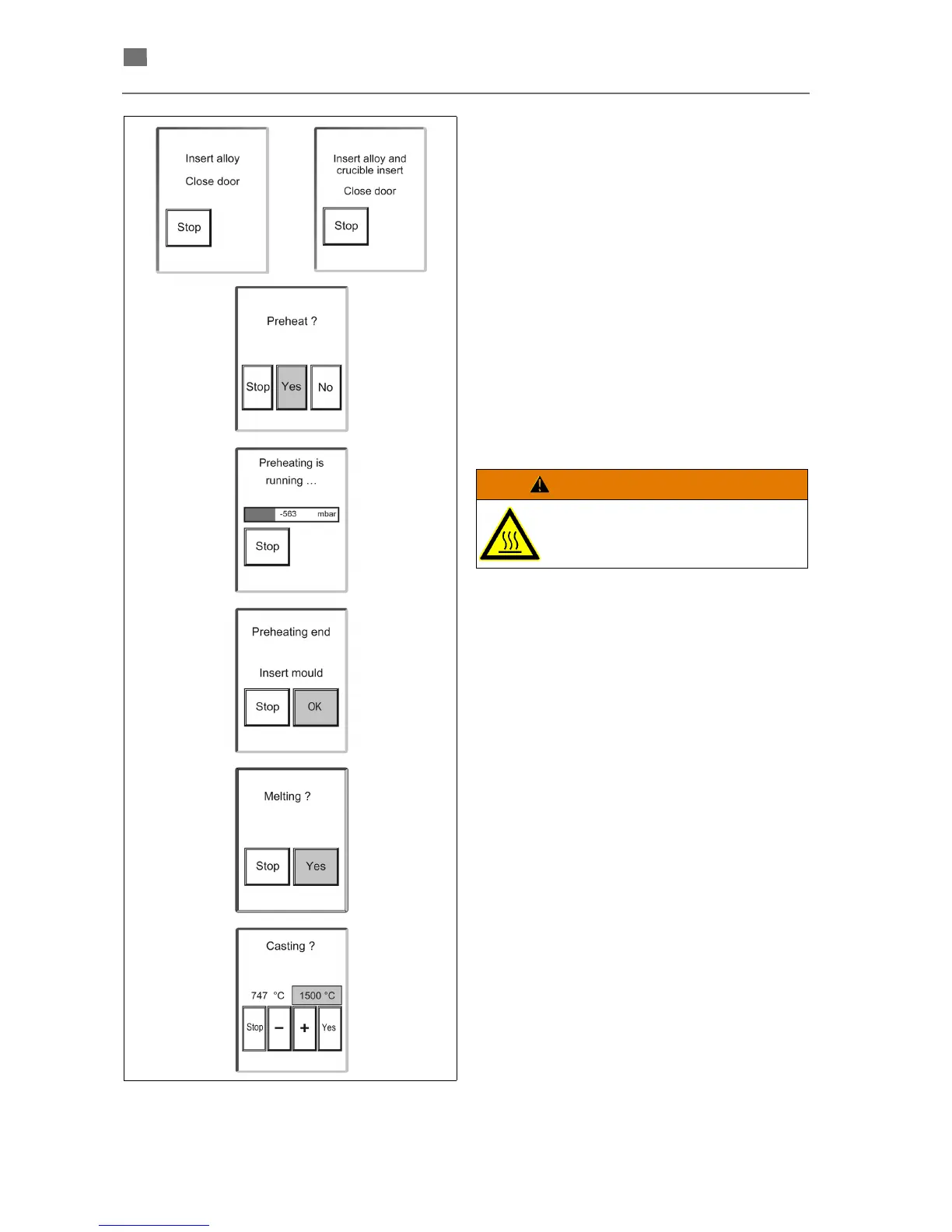

(The display on the right only appears for alloys that

require a crucible insert, see program table.)

When the crucible door is closed, the next display is

shown.

6. Confirm the preheating with „Yes“, or skip with

„No“.

In the case of crucible inserts, preheating must

be carried out:

"No" is missing on the display.

7. The chamber is evacuated during preheating.

8. The preheating may last for up to 60 seconds.

A signal sounds at the end.

9. If desired, it can be ended prematurely.

10. To prevent the alloy from cooling down unnec-

essarily: Get the moulds first, then press „OK“!

The preheating temperature and partial vac-

uum are maintained until then.

11. The next display is shown when the mould

door is closed.

12. The melting must now be confirmed with „Yes“.

The actual temperature and casting tempera-

ture are displayed.

(Only actual temperatures above 700 °C.)

13. Observe the melt and compare with the specifi-

cations on the display:

• If the ideal casting temperature is higher

than the one displayed, it must be

increased: First press the number field, then

the "+" key (10°C steps).

• If the ideal casting temperature is lower than

the one displayed, trigger the casting with

the "Yes" key and manually cast again at a

lower casting temperature (approx. -50 °C).

14. If the melt appears to be ready to cast, press

the "Yes" key to cast after observing the follow-

ing information.

Loading...

Loading...