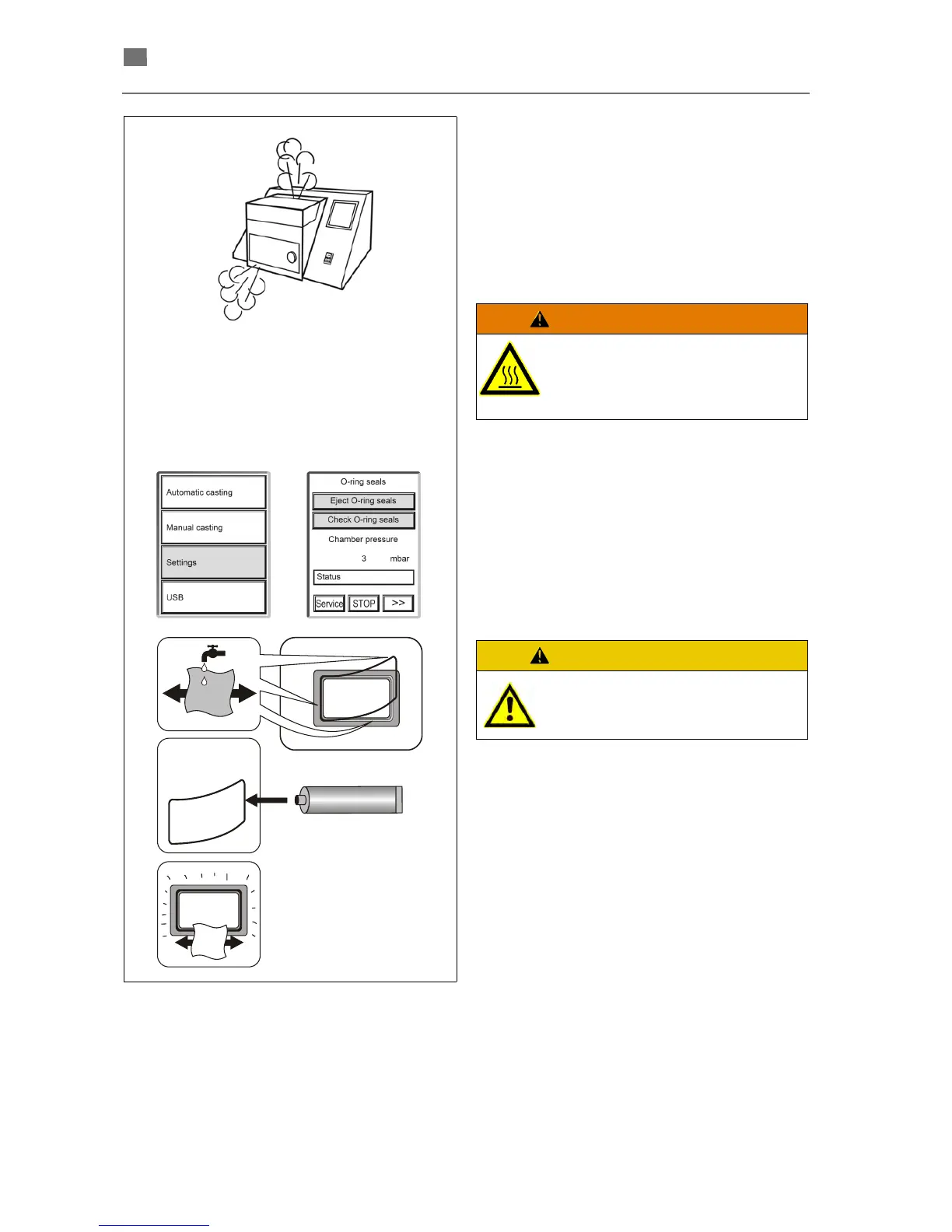

Clean seals (O-ring seals)

Leaks with noise generation may occur due to

contamination of the O-rings on the openings to the

casting chamber (for example, due to investment

material residues). Furthermore, vacuum and

pressure values may distort and thus cause the

casting result to be unsuccessful. To remove the O-

ring seals, they can be "ejected" with compressed

air.

1. Open crucible or mould door.

2. Select menu Settings / O-ring seals / Eject O-

ring seals: The O-ring seal is detached with

compressed air.

3. Remove the gasket.

4. O-Ring, Nuten und Dichtflächen mit einem

feuchten Tuch reinigen.

O-Ring sparsam mit Pflegefett (REF 16232)

einfetten.

5. Remove surplus grease with a dry cloth!

6. Do not overstretch the gasket when cleaning

and inserting!

7. Do not interchange the seals, they have differ-

ent sizes! A gasket with a poor fit leads to leak-

age.

8. Repeat the procedure on the second door (cru-

cible or mould door).

Risk of burns due to hot parts!

Carry out maintenance and cleaning

work before casting or only after the

machine has cooled down.

Loading...

Loading...