7

5. INSTALLATION

5.1 Location

BA304G and BA324G indicators have a GRP

enclosure and BA304G-SS and BA324G-SS

indicators have a 316 stainless steel enclosure.

Both provide IP66 ingress protection after a 7J

impact and have a thick armoured window which

will withstand a 4J impact. They are suitable for

exterior mounting in most industrial on-shore and

off-shore installations.

The indicators should be positioned where the

display is not in continuous direct sunlight. Special

conditions apply for Zone 0 installations, see

section 3.2.

Field wiring terminals are located on the rear of the

indicator assembly as shown in Fig 5c. Indicator

terminals 2 and 4 are internally joined and may be

used for linking the return 4/20mA wire - see

Fig 5c.

The indicators are surface mounting, but may be

pipe mounted using one of the accessory kits

described in section 9.4 or panel mounted as

described in section 9.5.

5.2 GRP models

BA304G and BA324G

The GRP models are fitted with a bonding plate to

ensure electrical continuity between the two

conduit or cable entries. The bonding plate may be

mounted on the inside or outside of the enclosure

and includes an M4 earth stud. If the carbon

loaded GRP enclosure is not bolted to an earthed

post or structure, this earth stud should be

connected to the plant potential equalising

conductor.

An insulated M4 stud is provided in the bottom

right hand corner of the GRP back-box for

interconnecting cable screens.

If field wiring is to be terminated prior to the

installation of the indicator assembly, the GRP

models, BA304G and BA324G, can be supplied

with an optional back-box terminal assembly,

which includes a 4/20mA continuity diode. See

section 9.6 of this manual. This option is not

available for the stainless steel models,

5.3 Stainless steel models

BA304G-SS and BA324G-SS

The stainless steel models have an earthing

terminal in the lower left had side of the back-box.

If the stainless steel enclosure is not bolted to an

earthed post or structure, this earth terminal should

be connected to the plant potential equalising

conductor.

An insulated M4 stud is provided in the bottom

right hand corner of the stainless steel back-box

for interconnecting cable screens.

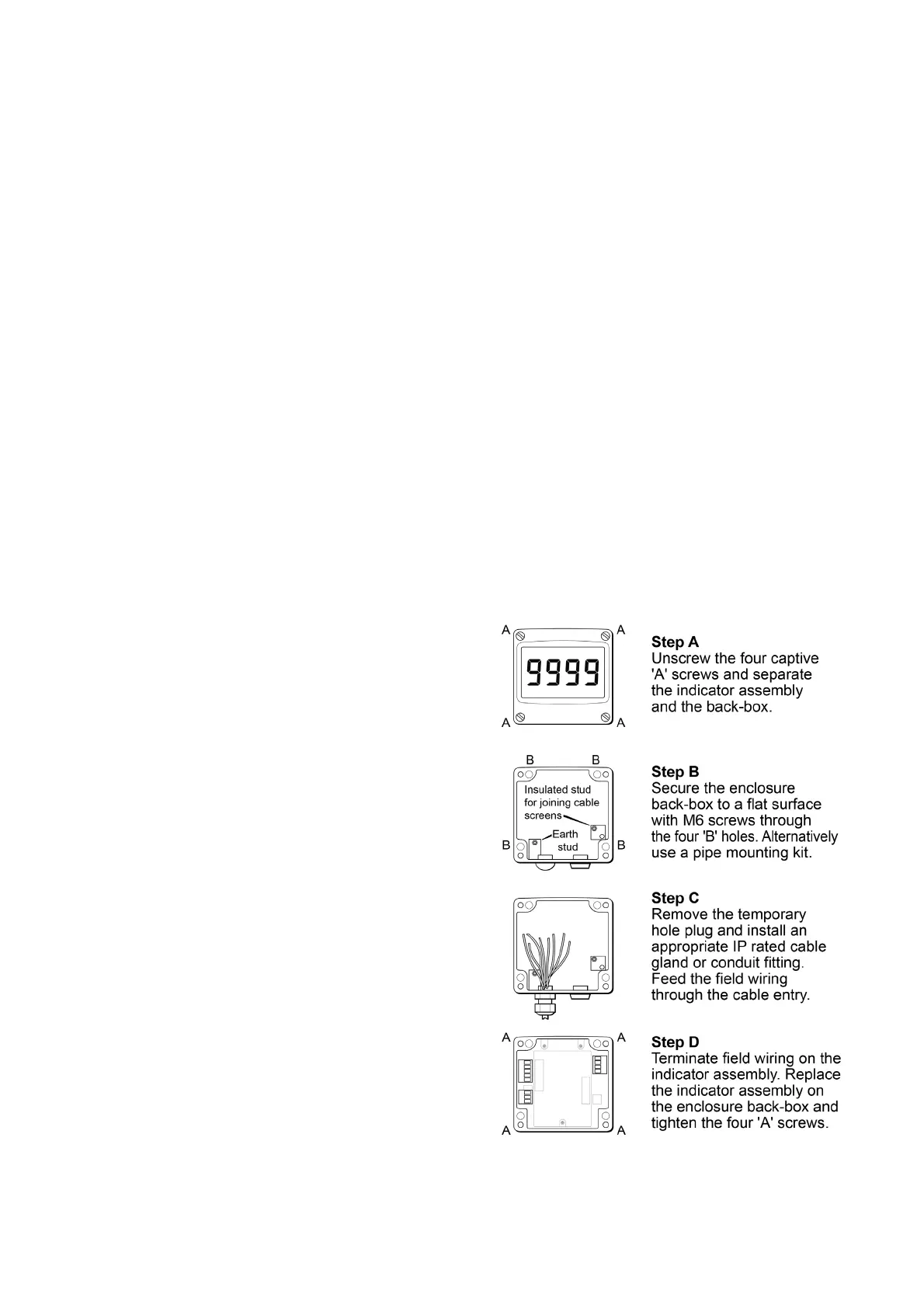

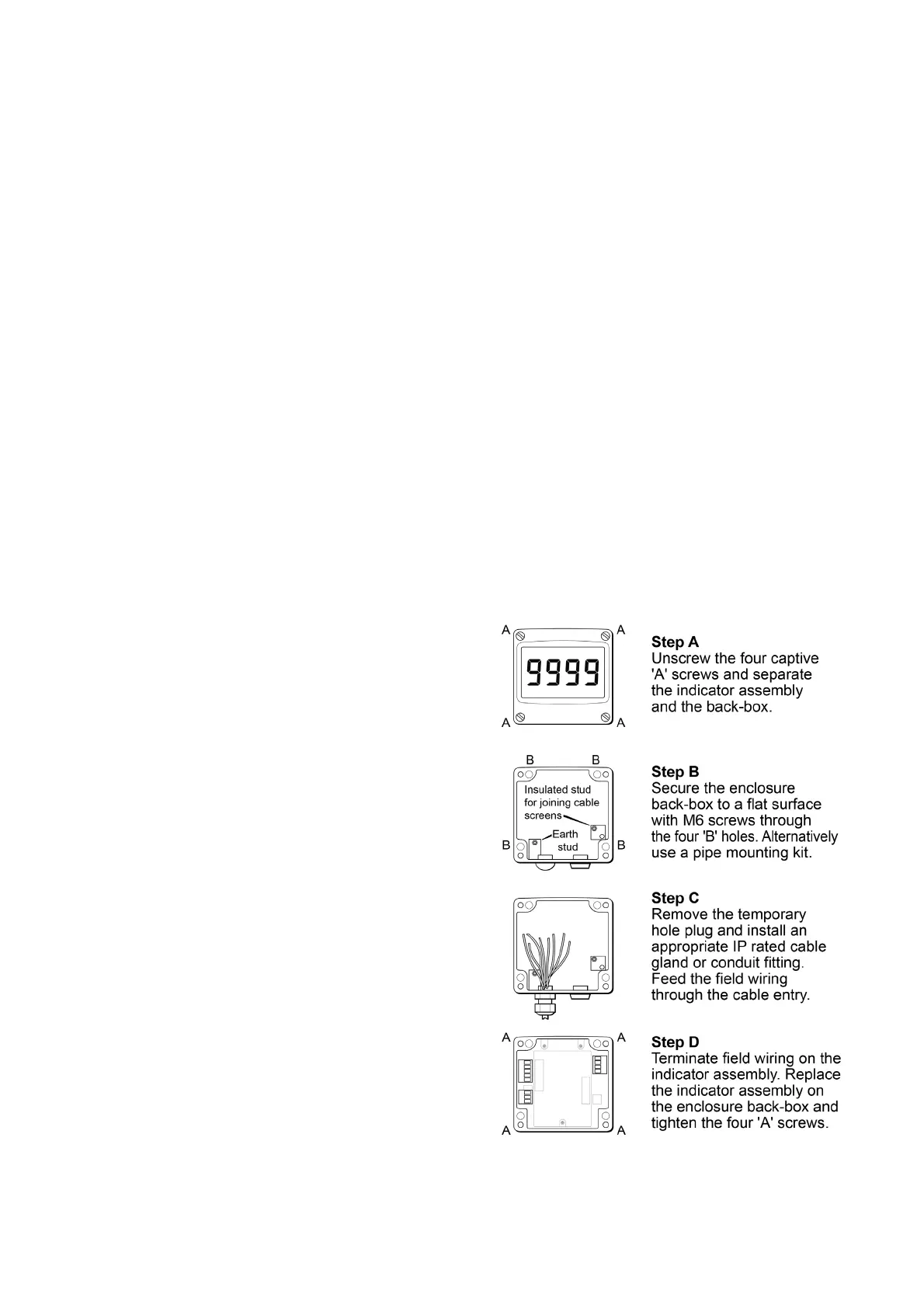

5.4 Installation Procedure

Fig 4 illustrates the instrument installation

procedure for all models.

A. Remove the indicator assembly by

unscrewing the four captive 'A' screws.

B. Mount the enclosure back-box on a flat

surface and secure with screws or bolts

through the four 'B' holes. Alternatively use

one of the pipe or panel mounting kits

described in sections 9.4 and 9.5.

C. Remove the temporary hole plug and install

an appropriate IP and temperature rated

cable gland or conduit fitting. If two entries

are required, the IP66 stopping plug should

be replaced with an appropriate IP and

temperature rated cable gland or conduit

fitting.

D. Connect the field wiring to the terminals as

shown in Fig 5c. Replace the instrument

assembly on the back-box and evenly tighten

the four 'A' screws.

Fig 4 BA304G, BA304G-SS, BA324G and

BA324G-SS installation procedure

Loading...

Loading...