V4. 12. 2010

.

Subject to modification

61

Starting point: Actuator in safe position

Procedure

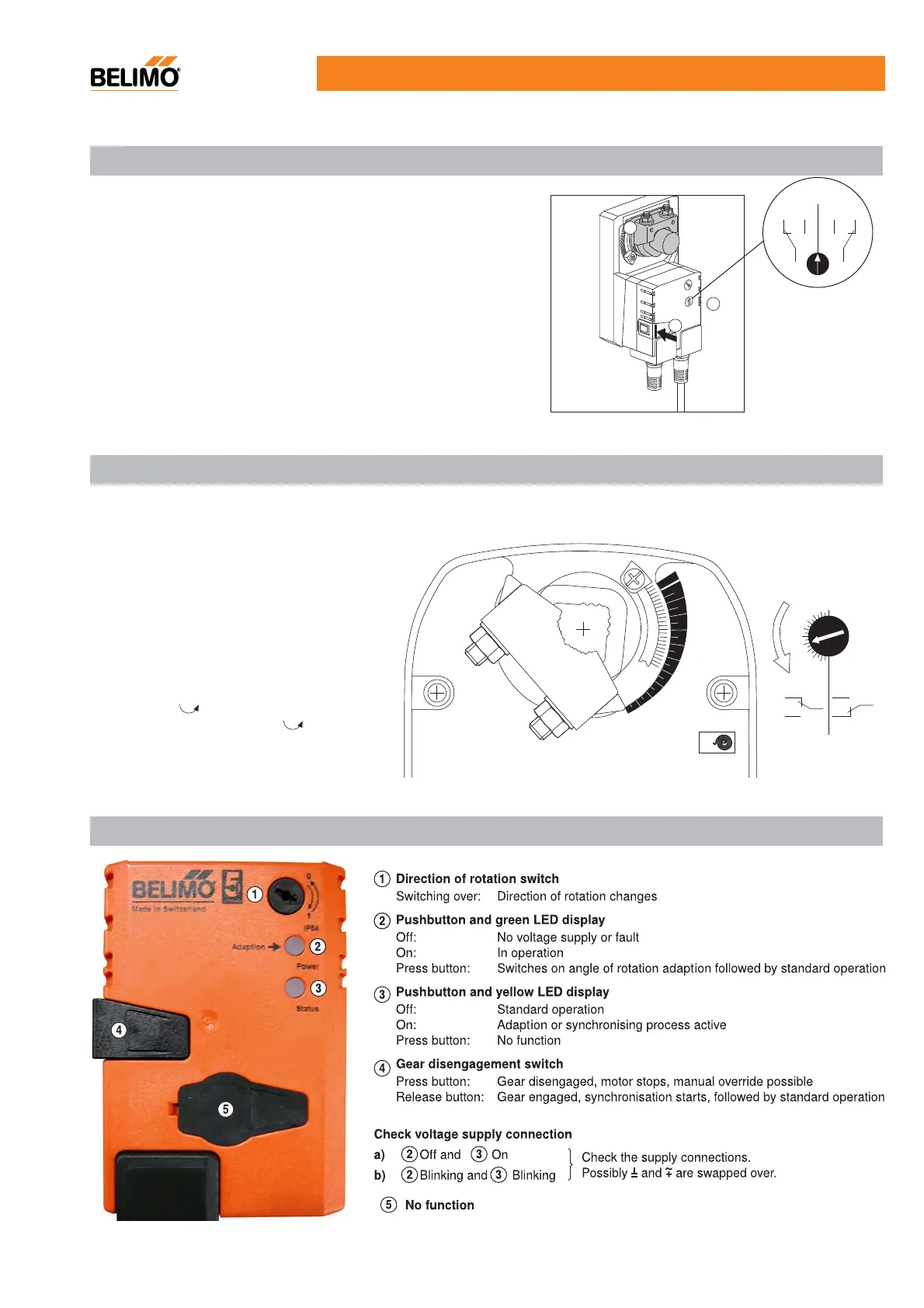

Turn the knob of the auxiliary switch until the

tip of the arrow is pointing to the required

switching position (see right). Example:

Switching point setting = 4 corresponds to

40% angle of rotation.

When the actuator runs to the operating

position (ccw ), the switch knob will also

rotate counter-clockwise (ccw ) and the

auxiliary switch will operate as the tip of the

arrow passes the scale zero (S1–S3 linked).

Auxiliary switch adjustment

Auxiliary switch adjustment for General Damper Actuators

1

1

2

S1

S2 S3

S1

S2 S3

1

0

.2

.4

.6

.8

S1

S2

S3

S1

S2

S3

0

.2

.4

.6

.8

1

R

Auxiliary switch adjustment for Mechanical Fail-Safe Damper Actuators

1. Press the pushbutton, manually operate the universal clamp to

desired switch position.

2. Turn switch pointer to the middle line.

3. When actuator moves clockwise (counter clockwise) to switch

position, switch indicator passes the middle line counter clockwise

(clockwise), the contact between S1 and S3 is disconnected

(connected) and the contact between S1 and S2 is connected

(disconnected).

Note: The switching point should be about 5° from the mechanical

end stops (1 short step on the scale).

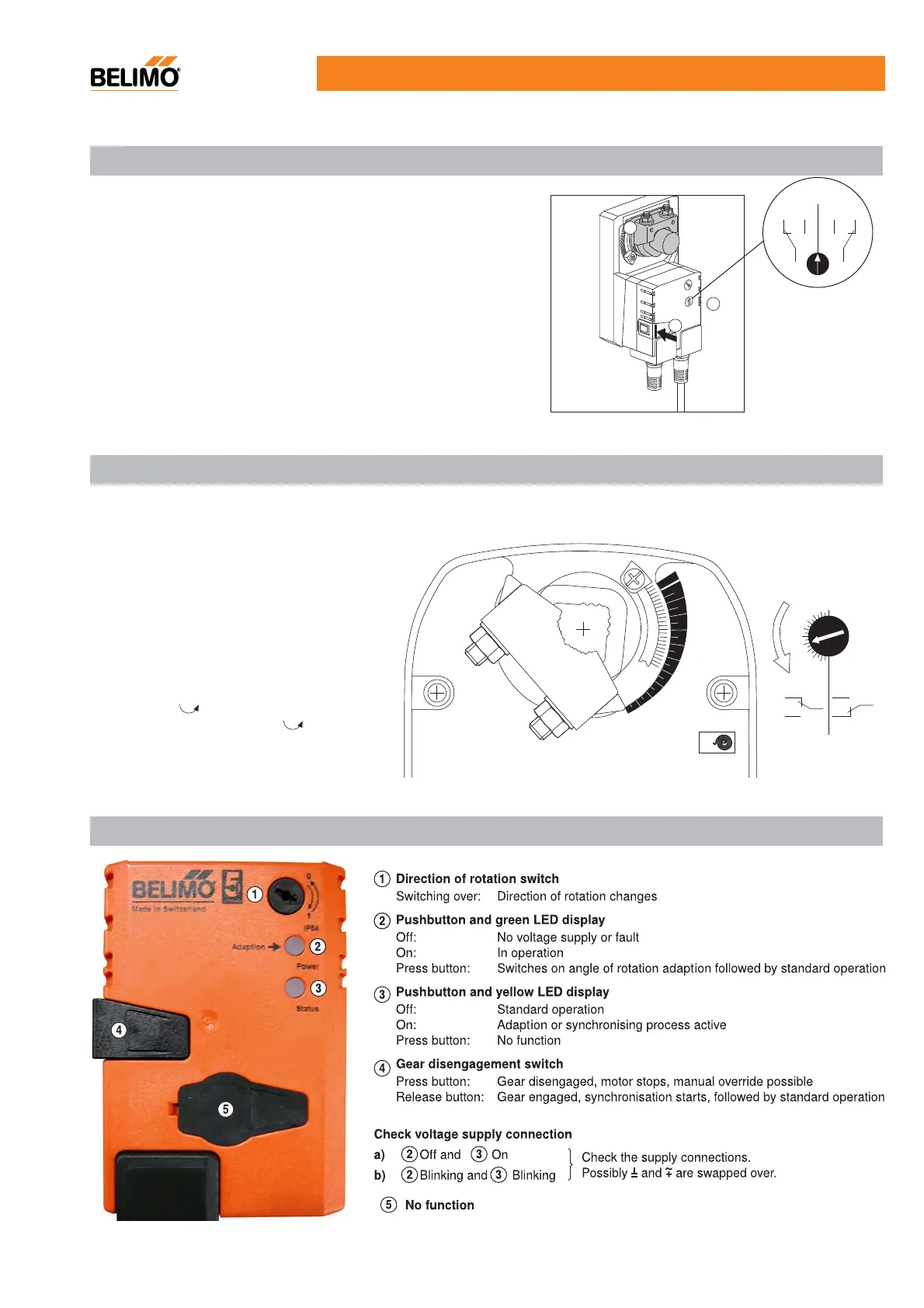

Fast Running Q.. Actuators operating controls and indicators

LF..-S (Mounting side R); NFU-S2, SFU-S2 (Mounting side L)

Loading...

Loading...