OPERATION

OPERATING INSTRUCTIONS

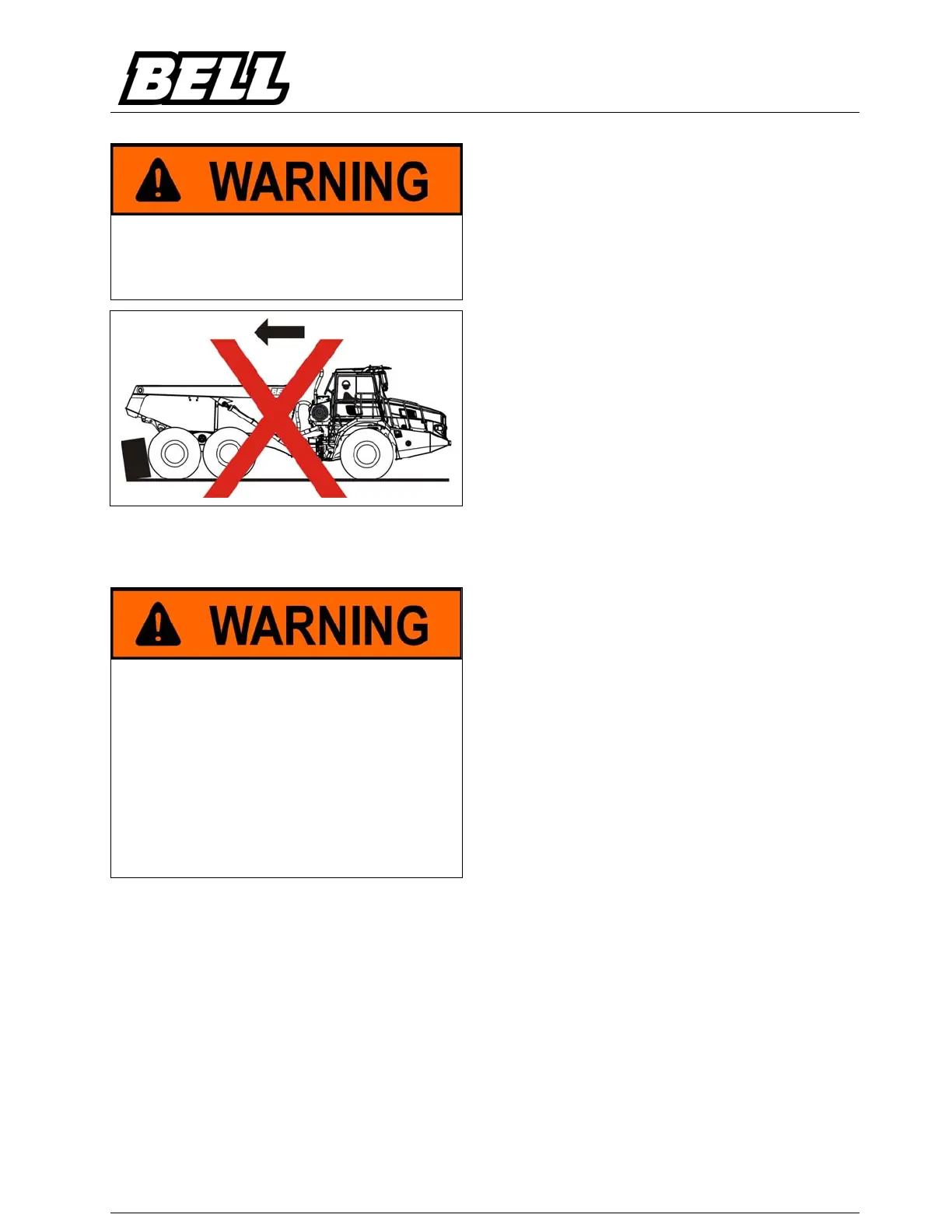

When reversing the machine to tip or load, be sure to

bring the machine to a complete stop using the brakes.

Do not let the wheels run into any bund walls or solid

structures, as this may lead to structural damage of the

machine.

Tipping

Be careful when tipping the bin. It is possible that the ma-

terial may stick to the bin and when the bin reaches a cer-

tain point, the front chassis may lift from the ground.

Also see Chapter SAFETY “ Avoid Tipping Over”

Do not operate the bin tip unless the transmission is

in Neutral (or dumping in 1st or Reverse). This practice

can over-ride the safety functions and could cause da-

mage to the machine and/or personal injury.

There is a risk that the ADT will “tip” over if the strut

fails and the tailgate does not open while tipping.

Clean out any blockage on the bin especially the area

that the tailgate rests on. This will insure that the tail-

gate closes fully and that no stress is put onto the leaf

struts.

• If the bin position is greater than 70% and the

transmission is in reverse, the engine torque will

be limited to 20% to avoid that the operator use

the bin as a scraper when fully tipped or drives in-

to a pile.

• When tipping a load from the bin, the centre of

gravity will continuously change and the condition

of the ground will determine the stability of the

machine.

• Special care must be taken when tipping sticky

material eg. wet clay or freezing material. Mate-

rial sticking to the bin will influence the stability of

the machine.

• Ensure there is sufficient space for the machine

before entering confined areas.

• Ensure that the bin tipping path is free of obstruc-

tion, such as overheard structures, Bund walls or

material stock piles. Tipping against such ob-

structions may restrict the bin movement resul-

ting in the tip cylinders being over pressurised

while try to force the bin, this could cause dama-

ge to the tip cylinders or their parts and may ren-

der them inoperable.

• Do not operate or stop too close to quarry edges,

ramp edges, quay edges and soft edges that may

collapse under the machine mass. The use of

stopping chocks or other safety devices is recom-

mended. Take special care during loading and

tipping as the machine mass changes during the-

se operations.

• Reverse up to the unloading site in a single,

straight manoeuvre so that you can maintain eye

contact at all times with the spotter and have all-

round vision from the machine.

• If a spotter is present follow only his instructions.

• Steer the machine so that it is straight and on le-

vel ground. The operator must have clear and

unobstructed vision through his rear view mirrors.

If the machine is articulated and not in the straight

ahead position the operator may find it difficult to

observe the spotter and the dumping action.

• The front and rear of the machine must be alig-

ned (no articulation) while tipping and loading, in

order to ensure maximum machine stability.

• When raising the bin ensure that when the bin is

fully raised it is no less than 3 metres (10’) away

from any power lines.

• Ensure that no personnel are near the machine

or dumping area.

• Ensure that there are no debris or obstructions

between the bin and chassis before lowering the

bin.

• Be aware of other machines and personnel when

entering or leaving the dumping area.

• Refer to machine's ability to signal warning for tip-

ping angle through the inclinometer. The roll per-

centage warning limit can be set between 5%

and 20% (default of 10%).

Operating Indoors

Machines may only be operated in buildings

approved by site management.

When operating the machine indoors ensure that

there is sufficient ventilation for the exhaust fumes

to escape.

Loading...

Loading...