1

The Procombi A comprises a range of high-efficiency

combination boilers with outputs to DHW of 28kW, 32kW,

and 36kW respectively. These appliances – by design

– incorporate electronic ignition, circulating pump,

expansion vessel, safety valve, pressure gauge and

automatic by-pass.

The Procombi range is produced as room sealed, category

II2H3P appliances, suitable for internal wall mounting

applications only. Each appliance is provided with a fan

powered flue outlet with an annular co-axial combustion air

intake that can be rotated – horizontally – through 360

degrees for various horizontal or vertical applications.

The Procombi A is approved for use with C13 & C33 type

flue applications.

These appliances are designed for use with a sealed

system only; consequently they are not intended for use

on open vented systems.

This booklet is an integral part of the appliance. It is

therefore necessary to ensure that the booklet is handed

to the person responsible for the property in which the

appliance is located/installed. A replacement copy can

be obtained from customer services.

INTRODUCTION

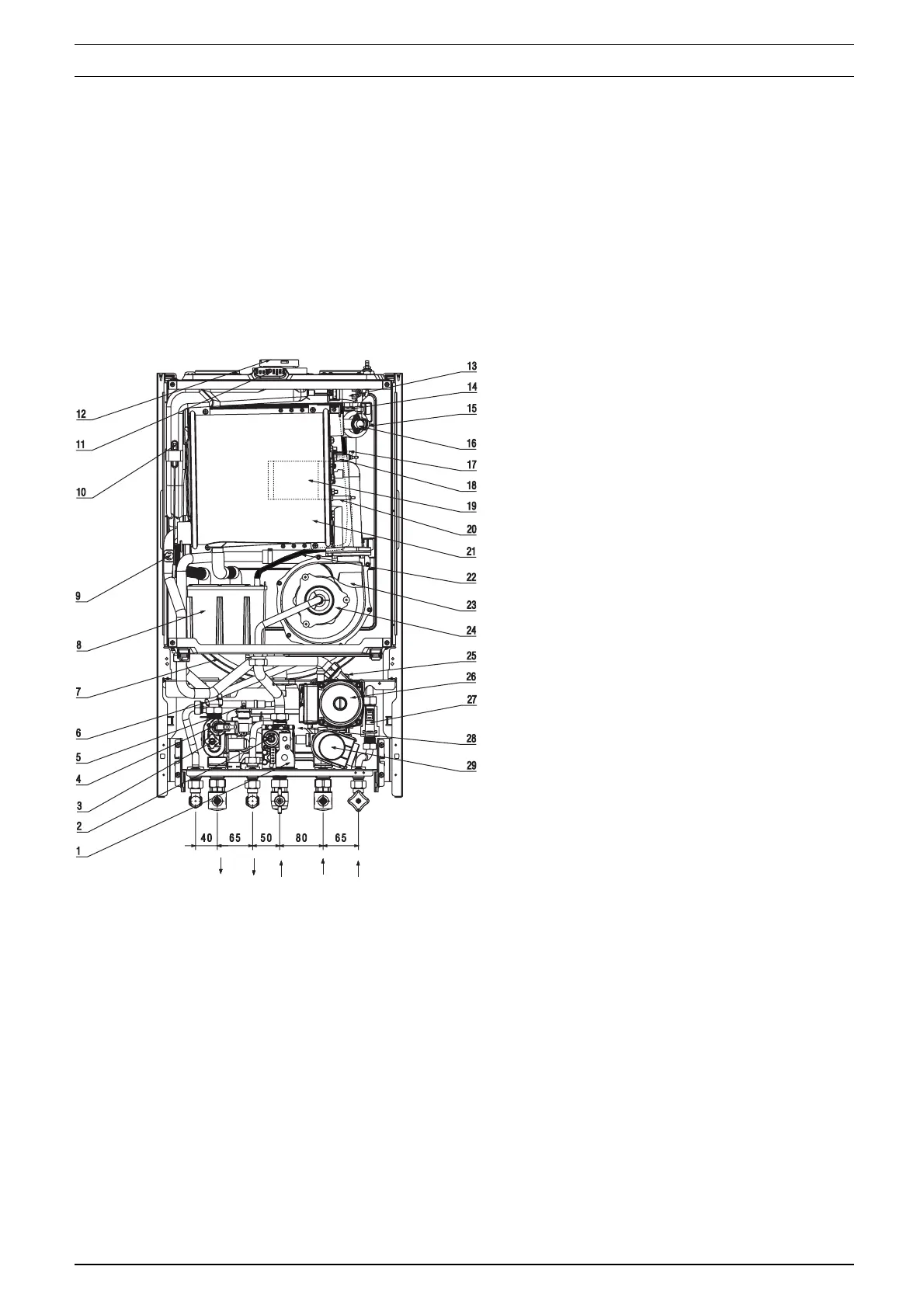

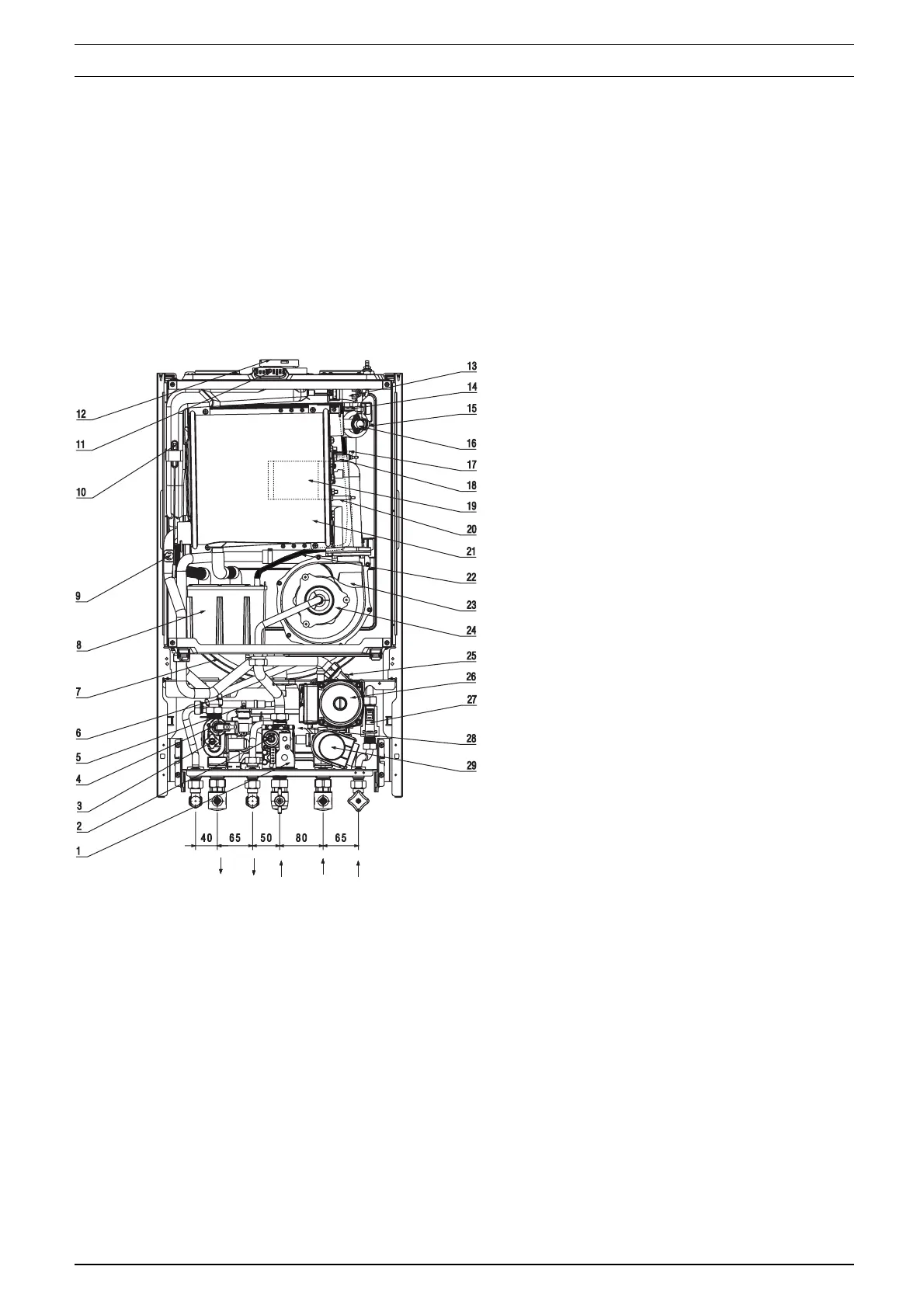

fig. 1

General layout (fig. 1)

1 Gas valve

2 Modulator coil

3 Discharge valve

4 Pressure switch

5 Domestic hot water sensor

6 Safety valve

7 Expansion vessel

8 Condense trap

9 Return sensor

10 Fumes thermostat

11 Flue gas analysis test point

12 Flue outlet & air intake

13 Ignition transformer

14 Top AAV

15 Flow sensor

16 High limit thermostat

17 Sensing Electrode

18 Spark Electrode

19 Cylindric Burner

20 Condensate level sensor

21 Main heat exchanger

22 Top AAV pipe

23 Fan assembly

24 Mixer

25 Bottom auto air vent (AAV)

26 Pump

27 DHW flow switch

28 Domestic hot water heat exchanger

29 Three porte valve actuator

F Heating flow connection

O Hot water outlet

G Gas connection

R Heating return connection

I Cold water inlet

G

O

I

R

F

Loading...

Loading...