4

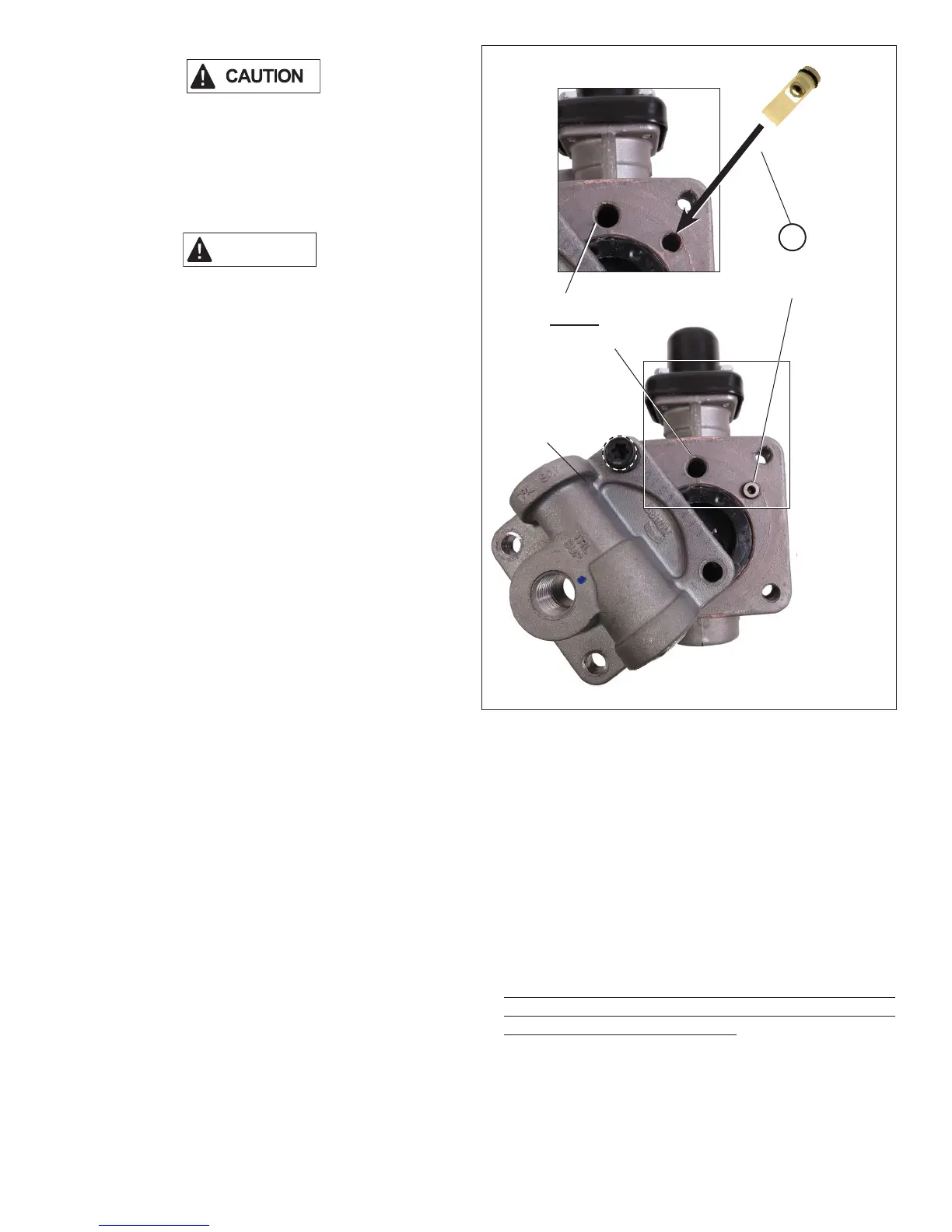

Figure 8 – Check Valve Cartridge Installation

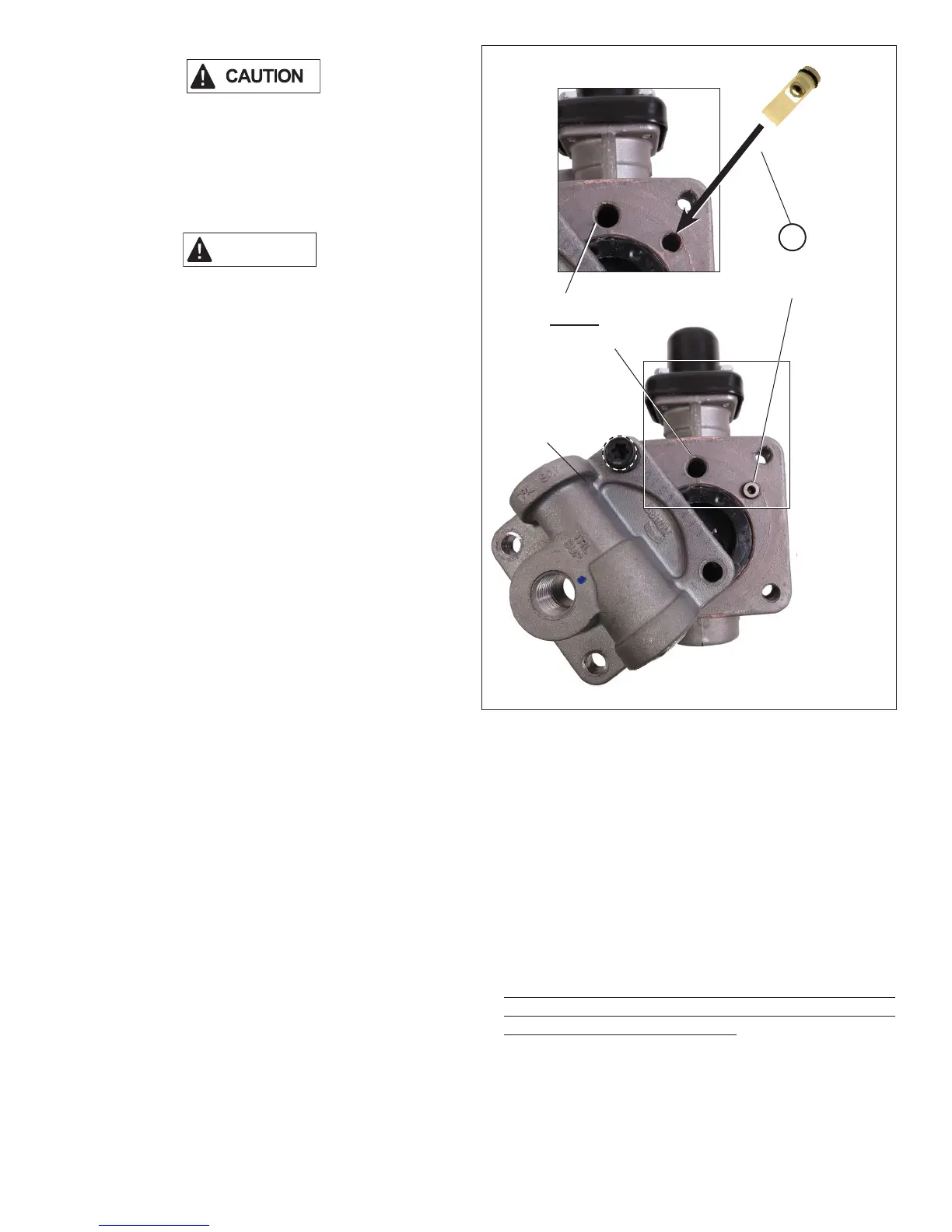

A

Control

Piston

Cover

ASSEMBLY

1. Ensure that the check valve cartridge (1) is intact as shown

in Figure 8.

2. Holding the larger diameter (o-ring end) of the check valve

cartridge (1), insert the pointed end into the air passage.

Push the check valve cartridge (1) in lightly with your nger

until it is ush with the body housing. (Refer to Figure 8.)

AT TENTION

THE CHECK VALVE CARTRIDGE (1) WILL FIT SNUGLY

INTO THE CORRECT AIR PASSAGE. DO NOT INSERT

THE CHECK VALVE CARTRIDGE (1) INTO THE LARGER

AIR PASSAGE.

3. Rotate the cover back into position and install the three

screws. Torque all four screws in a crossing pattern to

100 in-lbs. (A, C, D then B). (Refer to Figure 3.)

4. Reposition any ttings that may have been moved and

reconnect the air lines.

5. Perform the OPERATIONAL AND LEAKAGE TESTS

detailed below before placing the vehicle back into service.

OPERATIONAL AND LEAKAGE TESTS

This test can be performed by connecting the red trailer

gladhand to a tractor or an external air source. Check the air

source gauge against a gauge known to be accurate before

performing these tests.

1. Block all wheels or hold the vehicle by means other than

the air brakes: drain all pressure from the trailer reservoir.

2. Install a gauge in the trailer reservoir(s). Connect the air

source to the red supply gladhand of the trailer on which

the Bendix

®

SR-5

™

trailer spring brake valve is to be tested.

Build the trailer to full system pressure by placing the tractor

park control valve in the charge position, or by applying

an external air source. Make sure that the spring brake

chambers release before the reservoir starts to ll.

3. When full system pressure is reached – and the spring

brakes are fully released – apply a soap solution to the

control piston cover and ttings that were removed during

the repair. A one inch bubble in ve seconds is permissible.

4. Place the trailer air supply valve in the exhaust position,

or disconnect the external air source. The spring brakes

should apply. This will be evident by a full exhausting of

chamber pressure at the SR-5 valve exhaust port.

If the repair was completed correctly, the park brakes should

be set, and the reservoir pressure should hold steady with

no decay. If the valve does not perform properly, repeat the

installation procedure and retest.

5. Drain the reservoirs and remove the gauge that was

installed in the trailer reservoir(s) for testing purposes.

Reinstall the tting that was removed. Recharge the trailer

air system and check for leaks using a soap solution. A one

inch bubble in ve seconds is permissible.

6. For identication purposes, secure the green tie wrap (2)

through the identication hole located on the valve body.

(Refer to Figure 2.)

7. Included in this kit is an SR-5 decal (5) that can be placed

on the trailer upon completion of the valve installation.

The installation of this decal is not required; however, it

may be helpful for quick identication of the trailers that

have been serviced per the recall. Space is provided for

the technician's name and date of installation.

1

Check Valve

Cartridge

This port must remain

open. Do not install

the check valve here.

Loading...

Loading...