Do you have a question about the BENDIX TU-FLO 501 AIR COMPRESSOR and is the answer not in the manual?

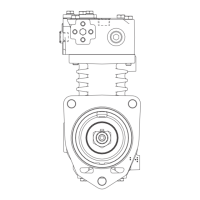

Details the compressor's function, construction, cooling, and mounting.

Explains how the compressor is driven, controlled by the governor, and its pressure regulation.

Details the air intake, compression, and unloader mechanisms in operation.

The compressor's function, duty cycle, and factors influencing it.

Requirements for proper discharge line setup and safety valve installation.

How the compressor is cooled, lubricated, and the impact of discharge line temperature.

Procedures for cleaning or replacing air strainers based on type and usage.

Tasks for maintenance every 6 months, 1800 hours, or 50,000 miles.

Checks for air supply, leaks, performance, and component conditions.

Steps for safely removing the compressor and initial disassembly preparation.

Procedures for disassembling cylinder head, crankcase, rods, and related parts.

Instructions for cleaning various internal and external compressor components.

Detailed checks for cracks, wear, and clearances in crankcase, cylinders, and pistons.

Discusses oil passing and methods to mitigate it using filters.

How to inspect crankshaft journals, bearings, and connecting rod bearings.

Methods for repairing or replacing valve seats and testing for leaks.

Steps for installing crankshaft, bearings, seals, end covers, and torque specifications.

Procedures for assembling pistons, connecting rods, and the unloader mechanism.

Steps for installing the cylinder head, gasket, and base plate or adapter.

Procedures for testing a rebuilt unit and essential safety warnings.

Instructions for using the guide and essential safety precautions for service.

Guidance on using and interpreting the oil test card, noting its limitations.

Explains the compressor's function, system integration, and duty cycle factors.

Details on discharge lines, temperature effects, and air dryer operation.

Instructions on navigating the guide and understanding its structure and indicators.

How to use and interpret the oil test card, noting its limitations.

Identifying oil leaks at compressor mounting flanges and connections.

Diagnosing oil leaks originating from the compressor's internal components.

Links reservoir oil to maintenance status, duty cycle, and leakage.

Addresses undersized compressors and air system leaks affecting oil levels.

How high temperatures and restricted discharge lines affect oil in the reservoir.

The effect of restricted air inlets on compressor performance and system air quality.

Addresses poor inlet air quality and potential crankcase flooding as oil sources.

Acceptable oil levels at valves and confirming normal system operation.

Diagnosing issues of excessive engine oil consumption and oil in the air dryer.

Identifying potential causes for slow air pressure build-up in the charging system.

How restricted discharge lines and inlet air affect air pressure build-up.

Causes related to poor inlet air quality and compressor failure leading to slow build.

Explains common reasons for the air charging system not building sufficient pressure.

Discusses why the compressor safety valve might release air.

Covers air dryer safety valve release and failure of the air dryer to purge.

Addresses reservoir safety valve release and compressor cycling problems.

Identifies common causes for air and coolant leaks from the compressor.

Addresses noisy compressor operation and other rare system problems.

Step-by-step tests for head gasket oil leakage and overall air system leakage.

Procedure to measure compressor discharge and air dryer inlet temperatures.

Procedures for testing governor malfunction and control line issues.

Procedure for testing the compressor unloader mechanism for leakage.

Explains the steps and decision points for conducting the BASIC test.

Guidance for technicians on completing the checklist and categorizing vehicle air use.

Procedure for draining and measuring oil and liquid from air tanks.

Using the test chart to determine action based on oil levels and days since last drain.

Performing the four-minute air brake system leakage test.

Recommendations for engine idling and discharge line setup in cold weather.

Focuses on identifying system leakage and proper reservoir draining.

Guidance on maintaining alcohol evaporator systems and air dryers.

Do's and Don'ts for safely thawing frozen air lines and preventing recurrence.

Importance of supporting lines and verifying automatic drain valve operation.

| Model | TU-FLO 501 |

|---|---|

| Manufacturer | Bendix |

| Cooling | Air Cooled |

| Type | Reciprocating |

| Stroke | 2.5 inches |

| Displacement | 12.4 CFM |

| Mounting | Flange |

Loading...

Loading...