Do you have a question about the BENDIX BX2150 AIR COMP-BW1424- and is the answer not in the manual?

Explains the function of the air compressor in air brake systems.

Details the process of air intake and compression by the piston.

Instructions for assembling the crankcase and crankshaft.

Detailed instructions for disassembling the cylinder head.

Instructions for disassembling the compressor crankcase.

Addresses oil leaks at compressor/engine connections and from the compressor.

Discusses maintenance, duty cycle, and temperature issues related to oil in reservoirs.

Addresses poorly filtered inlet air, compressor malfunction, and oil at valves.

Covers normal function, leakage, undersized compressor, unloader, and head gasket issues.

Addresses restricted discharge/inlet lines, poor inlet air, and compressor malfunction.

Lists causes like governor, discharge line, air dryer heater, and compressor malfunctions.

Explains how restricted discharge lines cause over-pressurization.

Discusses causes for the air dryer safety valve releasing air.

Addresses reservoir safety valve releasing air.

Addresses air leaks at connections, unloader malfunction, and head gasket damage.

Method to test for air leaks in the system and accessories.

Procedure to measure compressor and air dryer inlet temperatures.

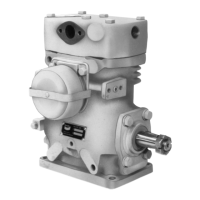

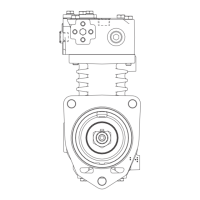

| Brand | BENDIX |

|---|---|

| Model | BX2150 AIR COMP-BW1424- |

| Category | Air Compressor |

| Language | English |

Loading...

Loading...