Do you have a question about the BENDIX TU-FLO 400-500-1000 AIR COMPRESSOR and is the answer not in the manual?

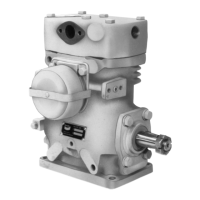

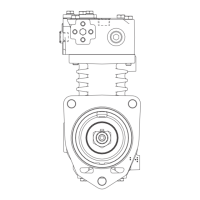

Details TU-FLO compressor models, their specifications, and cooling methods.

Explains the intake, compression, and unloading cycles of the compressor.

Explains the compressor's role within the air brake system and its components.

Discusses duty cycle, installation, and discharge line requirements.

Outlines essential maintenance tasks and schedules for system longevity.

Procedures for air leakage tests, and general removal/installation instructions.

Steps for cleaning, marking, and disassembling compressor parts.

Guidelines for cleaning compressor components like heads, blocks, and oil passages.

How to inspect compressor components like heads, valves, and seats for wear or damage.

Details on specific parts for self-lubricated types.

Steps for repairing discharge valves, seats, and inlet valves.

Guides for installing major components and assembling the unloader mechanism.

Instructions for baseplate installation, governor, and testing rebuilt units.

Introduces test procedures for head gasket leakage, system leakage, and temperature.

Step-by-step instructions for head gasket, system leakage, and temperature tests.

Step-by-step instructions for governor, unloader leakage, and control line tests.

Guide to diagnose problems and essential safety precautions for maintenance.

Explains the Bendix Air System Inspection Cup test and its usage.

Provides advice for operating air brake systems in cold weather conditions.

| Brand | BENDIX |

|---|---|

| Model | TU-FLO 400-500-1000 AIR COMPRESSOR |

| Category | Air Compressor |

| Language | English |