Do you have a question about the BENDIX BA-922 COMPRESSOR and is the answer not in the manual?

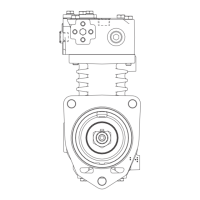

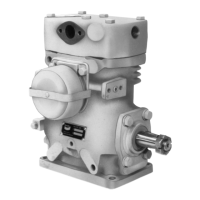

Provides overview of compressor function and components.

Explains how the compressor builds and controls air pressure.

Discusses issues related to oil presence in the air system.

Details methods and checks for compressor cooling.

Specifies requirements for air intake on the compressor.

Covers performance tests for compressor operation.

Details procedures for testing air system leakage.

Specific test for cylinder head gasket air leakage.

Tests for inlet, discharge, and unloader valve leakage.

Provides an overview of the disassembly process and considerations.

Lists available kits and parts for service.

Crucial safety precautions to avoid injury or death during service.

Steps for removing the compressor from the vehicle.

General guidelines for cleaning compressor components.

Specific cleaning instructions for the cylinder head.

Inspection criteria for head and valve plate surfaces.

Checks for cracks, wear, and thread damage.

Inspection of cylinder block gasket surface for damage.

Checks for kinks, damage, or carbon deposits in the discharge line.

Procedure for installing the crankcase cover.

Procedure for installing the crankcase end cover.

Steps for assembling the cylinder head components.

Essential safety guidelines for performing maintenance and tests.

Procedure to check for oil weeping from the head gasket.

Method for detecting air leaks in the brake system.

Checks compressor and dryer inlet temperatures.

Procedure to diagnose governor malfunctions.

Checks the governor control line installation and condition.

Tests for leaks in the compressor unloader mechanism.

Guides for performing the BASIC Test and interpreting results.

Guidance for operating air brakes in cold weather conditions.

Advice on minimizing engine idling to prevent freeze-ups.

Recommendations for discharge line length and insulation.

Specific recommendations for high duty cycle vehicles.

Methods for checking air brake system leakage.

Importance and procedure for draining reservoirs.

Operation and maintenance of alcohol systems.

Information on air dryer operation and service.

Tips for preventing and thawing frozen air lines.

Ensuring proper support for lines to prevent damage.

Maintenance and checking of automatic drain valves.

| Brand | BENDIX |

|---|---|

| Model | BA-922 COMPRESSOR |

| Category | Air Compressor |

| Language | English |

Loading...

Loading...