Do you have a question about the BENDIX TU-FLO 750 COMPRESSOR and is the answer not in the manual?

Explains intake, compression, and unloaded states of the compressor.

Essential maintenance schedules and intervals for system reliability.

Methods to test for unloader piston and discharge valve leakage.

Step-by-step instructions for removing and taking apart the compressor.

Detailed steps for disassembling crankcase, connecting rods, and bearings.

Procedures for inspecting piston rings, crankshaft journals, and bearings.

Specific instructions for repairing unloader and discharge valve mechanisms.

Guides for installing the crankshaft, connecting rods, pistons, and rings.

Steps for completing the compressor assembly and final checks.

Procedures for testing the compressor after rebuild to ensure proper function.

Key technical data and performance parameters for the compressor.

How to use the troubleshooting section and general safety precautions.

Comprehensive safety warnings and precautions for working on vehicle systems.

Recommended maintenance intervals based on vehicle usage and compressor type.

Instructions on navigating the troubleshooting section to find solutions.

Critical safety warnings to follow before performing any maintenance or troubleshooting.

Diagnoses the presence of oil in air reservoirs and initial checks.

Diagnoses causes for slow air pressure build-up in the charging system.

Addresses issues where the air charging system fails to build air pressure.

Introduction to the Bendix Air System Inspection Cup (BASIC) test and its purpose.

Guidance on interpreting test results using the acceptance lines on the BASIC cup.

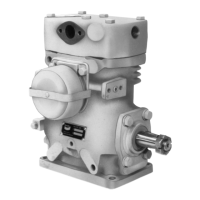

| Brand | BENDIX |

|---|---|

| Model | TU-FLO 750 COMPRESSOR |

| Category | Air Compressor |

| Language | English |

Loading...

Loading...