6

If a previously unturbocharged compressor is being turbo-

charged, it is recommended that the inlet cavity screen

(238948) be installed with an inlet gasket (291909) on both

sides of the screen.

COMPRESSOR TURBOCHARGING

PARAMETERS

Air entering the compressor inlet during the loaded cycle

must not exceed 250 degrees Fahrenheit (121 degrees Cel-

sius). A metal inlet line is suggested to help meet this

parameter.

The following compressor crankshaft rotative speed and in-

let pressure relationships may not be exceeded.

Crankshaft Maximum CompressorR.P.M.

Inlet Pressure

1900 RPM 30.0 psi (207 kPa)

2000 RPM 27.5 psi (190 kPa)

2100 RPM 24.0 psi (165 kPa)

2200 RPM 21.0 psi (145 kPa)

2300 RPM 19.0 psi (131 kPa)

2400 RPM 16.0 psi (110 kPa)

AIR INDUCTION

One of the single most important aspects of compressor

preventive maintenance is the induction of clean air. The

type and interval of maintenance required will vary depending

upon the air induction system used.

The intervals listed under the headings below pertain to typi-

cal highway and street operation. More frequent maintenance

will be required for operation in dusty or dirty environments.

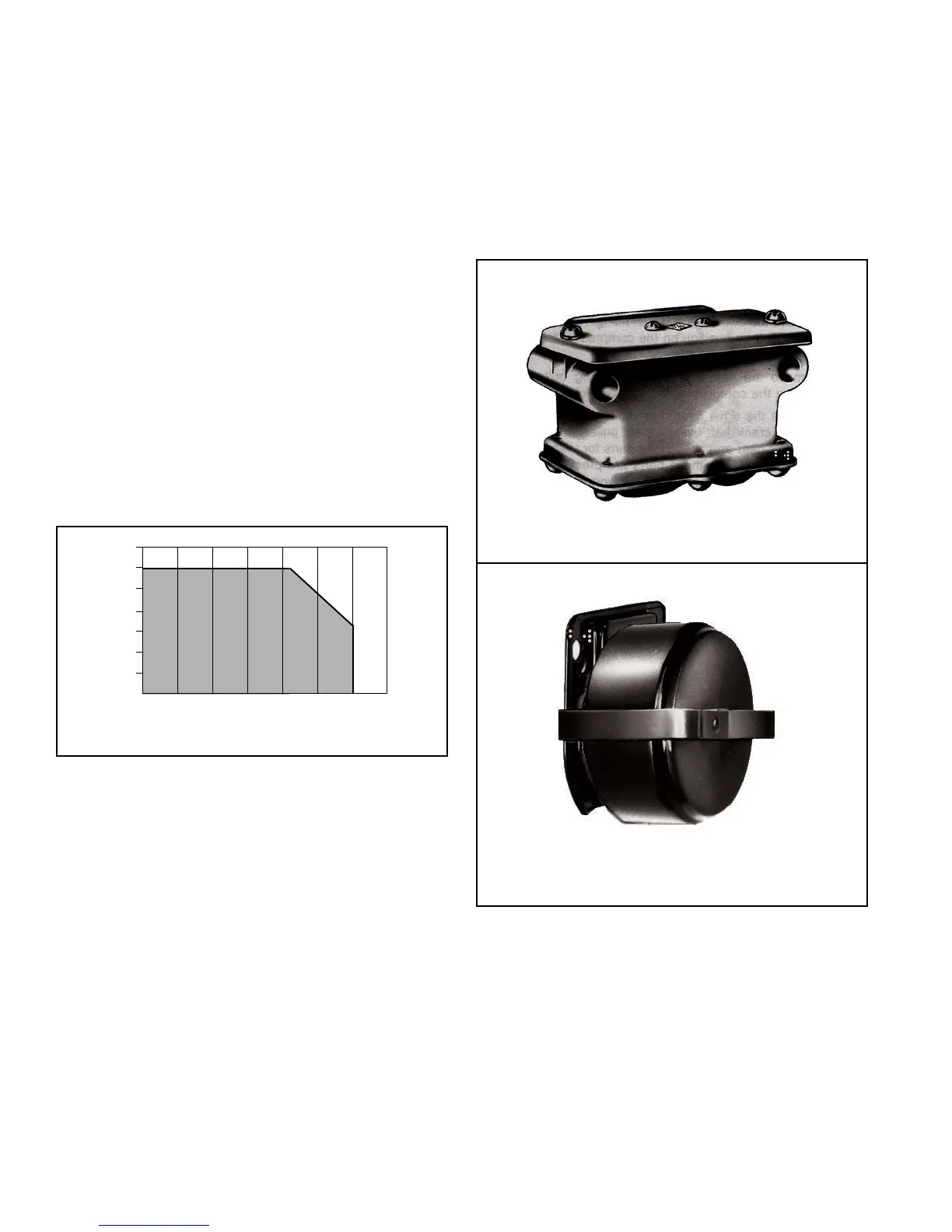

0

20

25

15

35

5

30

270024002100180015001200900600

10

Compressor Speed (RPM)

Inlet Pressure (PSIG)

Turbo Limits

FIGURE 9 - TURBO LIMITS CURVE

PREVENTATIVE MAINTENANCE

Regularly scheduled maintenance is the single most impor-

tant factor in maintaining the air brake charging system.

Refer to Table A in the Troubleshooting section for a guide to

various considerations that must be given to the mainte-

nance of the compressor and other related charging system

components.

Important Note: Review the warranty policy before perform-

ing any intrusive maintenance procedures. An extended

warranty may be voided if intrusive maintenance is performed

during this period.

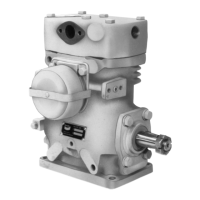

PAPER AIR STRAINER DRY ELEMENT-PLEATED

POLYURETHANE SPONGE STRAINER

FIGURE 10 - STRAINERS

POLYURETHANE SPONGE STRAINER

Every month, 150 operating hours or 5,000 miles, which-

ever occurs first, remove and wash all of the parts. The

strainer element should be cleaned or replaced. If the ele-

ment is cleaned, it should be washed in a commercial solvent

or a detergent and water solution. The element should be

saturated in clean engine oil, then squeezed dry before re-

placing it in the strainer. Be sure to replace the air strainer

gasket if the entire strainer is removed from the compressor

intake.

Loading...

Loading...