Do you have a question about the BENDIX DURAFLO 596 COMPRESSOR and is the answer not in the manual?

Guidelines for installing the compressor.

How the compressor is lubricated by the engine.

Methods used to cool the compressor.

Crucial upkeep procedures for the compressor.

Issues related to oil in the air system.

Test for air build-up time.

Post-installation performance testing.

Critical safety instructions for maintenance.

Test for head gasket oil seepage.

Test for air leaks in the system.

Measures compressor and dryer inlet temps.

Checks governor function and settings.

Inspects governor control line installation.

Tests for unloader mechanism leaks.

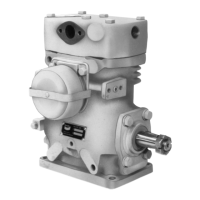

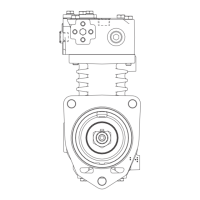

| Brand | BENDIX |

|---|---|

| Model | DURAFLO 596 COMPRESSOR |

| Category | Air Compressor |

| Language | English |

Loading...

Loading...