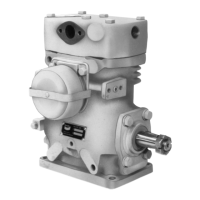

DESCRIPTION

The function of the air compressor is to provide and

maintain air under pressure to operate devices in air brake

systems. The Bendix

®

360cc compressor is a single-

cylinder compressor with a rated displacement of 15.8 cubic

feet per minute at 1250 RPM. The compressor consists

of an integral water-cooled cylinder head assembly and

water-cooled crankcase.

The cylinder head assembly is made up of an aluminum

cylinder head, an aluminum cooling plate, and a steel valve

plate assembly with two sealing gaskets. The cylinder head

contains air and water ports. The cooling plate, situated

between the head and valve plate, assists in cooling the

head assembly. The valve plate assembly, consisting of

brazed steel plates, has separate valve openings and

passages to allow air and coolant to fl ow in and out of the

compressor. See Figure 1 for an external view, and Figure

3 for an exploded view

.

The compressor is equipped with a safety valve in the

cylinder head safety valve port, directly connected to the

discharge port. The safety valve protects the compressor

head in the event of excessively high discharge line

pressure, for example, in the event of blockage downstream

of the compressor. Excessive air pressure causes the

safety valve to unseat, releases air pressure and gives an

audible alert to the operator.

The compressor is cooled by air fl ow, as well as by engine

coolant. The engine coolant fi rst enters the crankcase

water jacket to cool the cylinder bore, then passes through

passages in the valve plate assembly, cooling plate, and

cylinder head and then out of a port at the top of the

compressor, back to the engine.

A nameplate is attached to a fl at cast face on the side of

the crankcase. It is stamped with information identifying

the compressor designation, customer piece number,

compressor assembly part number and serial number.

See Figure 2

.

GENERAL INFORMATION

This Bendix

®

360cc compressor is a “discharge line

unloader” (DLU)-style compressor, meaning that the

compressor pumps continuously, unlike some compressor

designs which use an "unloader" mechanism in the

compressor head to switch from a pumping mode to a

non-pumping mode. Instead, the control of air delivery to

the vehicle’s air system is managed by using a separate

discharge line unloader valve mounted in parallel with a

turbo cut-off style of air dryer (see Figure 6).

SD-01-3121

BENDIX

®

360CC SINGLE CYLINDER COMPRESSOR FOR

INTERNATIONAL MAXXFORCE

™

11 AND 13 BIG BORE ENGINES

MAXXFORCE

™

is a trademark of International Engine Intellectual Property Company, LLC.

FIGURE 1 - BENDIX

®

360cc SINGLE CYLINDER

COMPRESSOR

FIGURE 2 - NAMEPLATES (TWO STYLES)

Safety

Valve

Cooling

Plate

Valve Plate

Assembly

Cylinder

Head

Crankcase

Coolant

Enters Here

Locating

Pins

Coolant Exits at

Top of Head

(See Figure 7)

Bendix Part Number . . . . . . A

Customer Piece Number . . . . B

Compressor Serial Number . . C

A

B

C

A

B

C

Loading...

Loading...