-13-

-14-

6). Non-parallel surface

To get a satisfying ultrasonic response, the surface must

have its one measuring side parallel with another, other-

wise will obtain wrong result.

7). Influence of the material temperature

The size & sound velocity of material will change with the

temperature, when the precision is critical, please make

measurement in 2 samples of the material under the same

temperature to determine the proper reading resulting

from the temperature. When taking measurement for st-

eel parts in high temperature, this method may be adop-

ted to obtain the correct reading.

8). High acoustic reduction material

For materials in fiber, poriferous or big granular, acoustic

dispersion will cause the energy attenuation that may

result in abnormal readings(practically the reading less

than the actual thickness), in this case the material is not

suitable for the unit.

9). Reference sample block

For calibration for the gauge, a given thickness or sound

velocity of the material is very import. Calibration needs

at lest one referring standard sample block. This gauge

is provided with a 4.0mm sample block, please check for

calibration operations.

In different material & situation, only one sample block

may not satisfy every calibration. The more similar sample

block, the more exact reading obtained. Ideally, referring

block is a group of different thickness and same material,

by calibrating to the referring block, the effect of variation

of sound velocity will be minimized. To get the most exact

measure, a set of referring block is very important.

When measuring thin material which thickness close to

the minimum limit range of this unit, please use a referring

block to define exact limit of this material. Do not measu-

ring the material that the thickness under the minimum limit.

10). The wear of the transducer will effect the measurement,

when below situation happen, please replace the

transducer:

A. only display one reading when measured different

thickness;

B. reading display without take measurement.

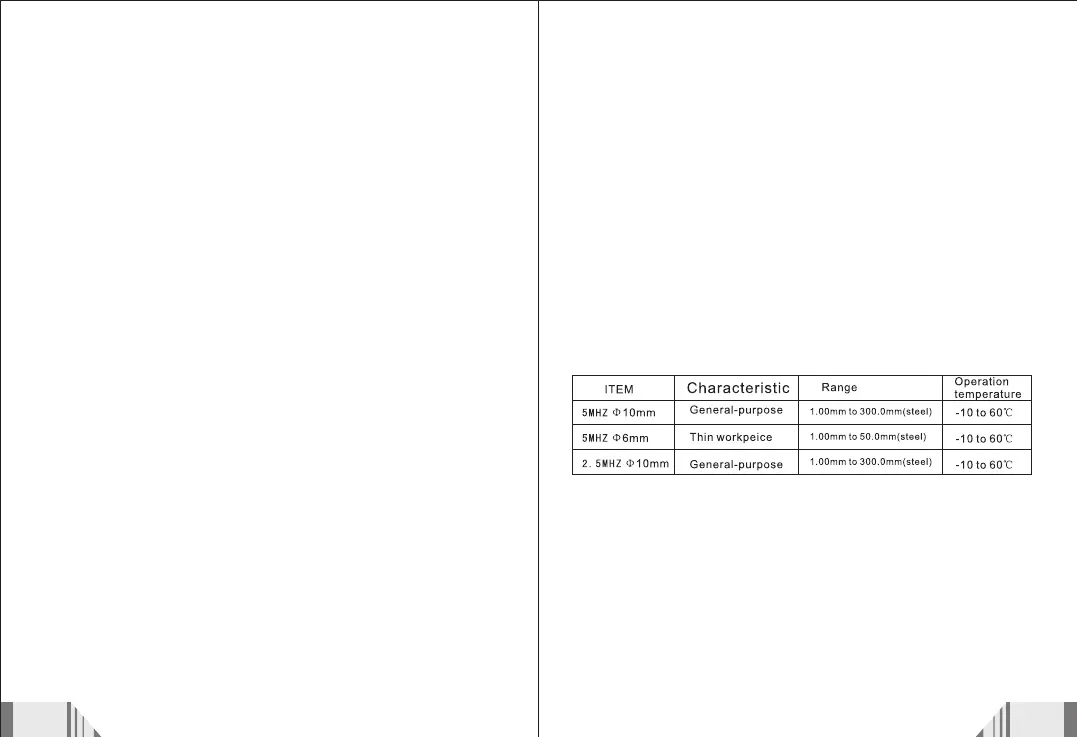

11). Selection of transducer

A

1

2

3

4

5

6

A

DOCUMENT NO.: QR-208/A

B C D E

B

C

D E

1

2

3

4

5

6

SCALE

SIZE

DATENAME

APPROVALS

APP. BY

CUSTOMTER

DRAWN BY

CHECKED BY

1:1

A4

更 改 记 录

次号

1.

2.

3. 12页内容修改 19.11.22

VER.A4

SHEET

OF

PART Number:

1 1

GM130 英文有唛新说明书示意图

日期

更 改 内 容

7160130008

QWY

2017-5-13

SHENZHEN JUMAOYUAN SCIENCE AND TECHNOLOGY CO., LTD.

4.修改 配件 探头 单位 2021-07-09

7160130008 GM130 英文有唛新说明书

材料:105G双铜;

成品尺寸:190*130MM;

公差:+-1.0MM;

页数:24P;

工艺:双面单色印刷,加工:骑马钉

VER-A4

Loading...

Loading...