15

120001 Rev K 1-19-18

Step 1: Determine the type of supply line needed from the model number’s 7th position on the

serial tag. If the model number is 3711SNR (Note the R) the dispenser will require a submerged pump

and pressurized supply line for each product. If the model number is 3711SNS (Note the S) the pump

will require a suction supply line for each product.

Step 2: Determine the number of product pipes required by finding the model number below.

Model Number Product Supply Lines Required

3711 / 3811 Use 1 product line plumbed to position 1.

3712 / 3812 Use 1 product line plumbed to position 1.

3722 / 3822 Use 1 product line plumbed to position 1 and 1 product line plumbed to position 2.

*Refer to base drawings in the back of this manual for product inlet locations.

Pipe Size - The 3000 Series do not come with an inlet pipe or joint. The customer is responsible for the

1 1/2” NPT inlet pipe. These will thread directly into the inlet casting (see figure 7, figure 8 and figure 9).

Determining the Number of Product Supply Pipes Needed

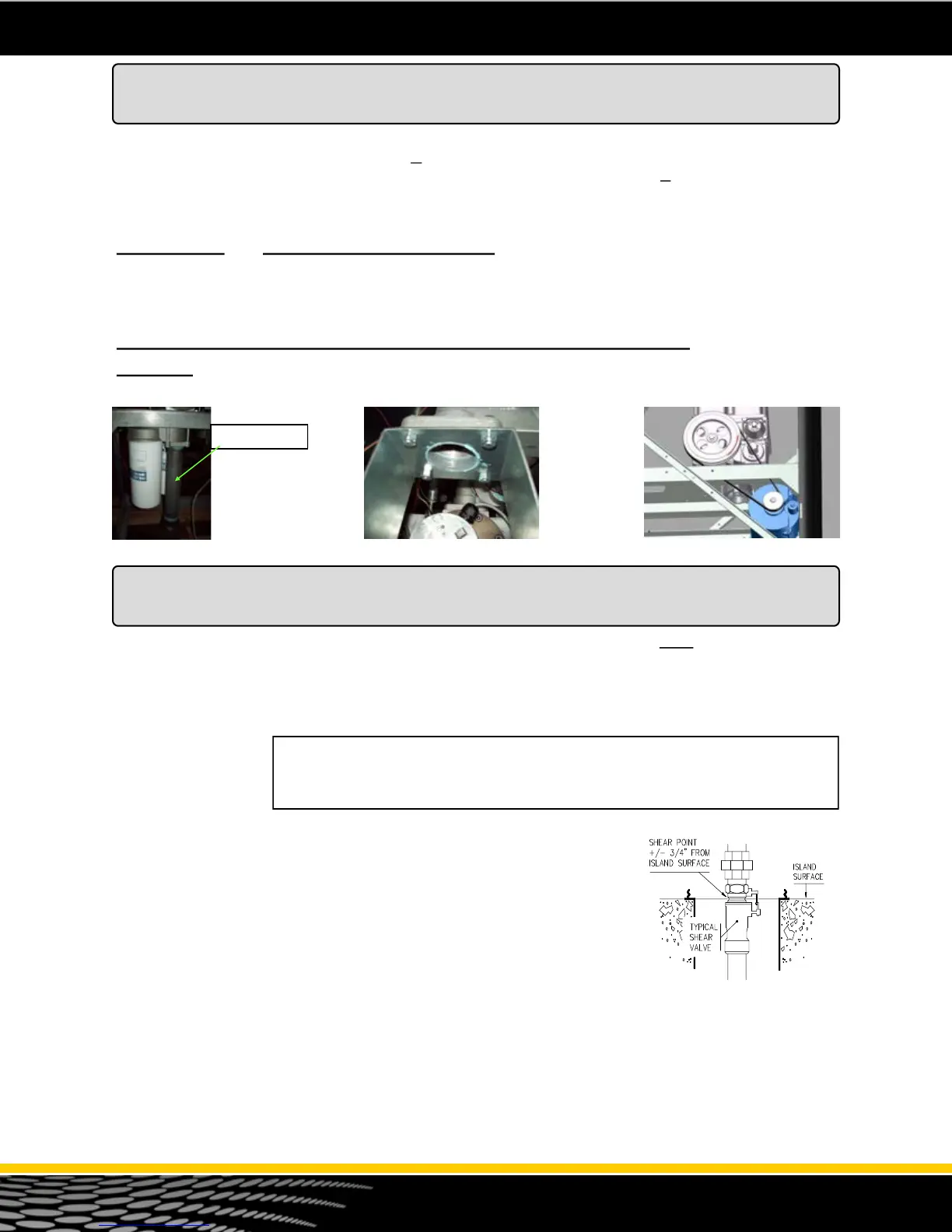

For remote dispensers, a U.L. Listed Emergency Shut Off Valve is required for each product inlet. The

Emergency Shutoff Valve can be referred to as an “Impact Valve”, “Safety Valve”, “Shear Valve”,

“Crash Valve”, or “Fire Valve”. The Emergency Shut Off Valve must be supported by the island frame or

containment sump frame. Follow all instructions contained in the valve’s installation manual and

observe all national, state, NFPA, and local codes.

For self-contained

(suction) pumps, a

vertical check valve is

required under each

of the pump’s ground

joint unions for the product inlet. The vertical check valve ensures that the

pump’s hydraulic system remains full of product, and it is necessary to

maintain the “prime” of the suction line so that liquid product does not drain

back to the tank. Follow all instructions contained in the vertical check

valve’s installation manual and observe all local codes.

Product inlet locations and dimensions are on the footprint foundation

drawings in this manual.

Listed ground joint union must be installed between sheer section of

Emergency Shut Off valve and dispenser inlet. If rigid product inlet pipes

are used, they must be plumbed so no strain is exerted on the dispenser chassis caused by tightening

down the unions.

For dispensers used with companion satellites, follow all federal, state, and local codes regarding

installation of impact valves.

Install an approved emergency shut off valve, designed to close automatically in the event of severe

impact or fire exposure, in the dispenser supply line at the base of the dispenser. The valve will also

permit safe inspection and maintenance. Follow the installation instructions for the valve being

installed (see figure 10).

Mechanical and Plumbing Notes

Figure 8 - Satellite Figure 7 - Master Big Fueler

Not Included

Figure 9 - Big Fueler Suction

Figure 10 - Shear Valve

Loading...

Loading...