B) Drop Sequence

2

1

5

3

4

6

Surface

2. Front

3. Bottom

4. Rear

5. Right

6. Left

1. Top

Manufacturing

joint

-Corner 5-3-2 select

at weakness side [the low left(or right) corner of the front panel]

-An edge drop with impact on the shortest edge radiating from corner 5-3-2

-An edge drop with impact on the next shortest edge radiating from corner 5-3-2

-An edge drop with impact on the longest edge radiating from corner 5-3-2

-A flat drop with impact on the rear

-A flat drop with impact on the front

-A flat drop with impact on the right

-A flat drop with impact on the left

-A flat drop with impact on the bottom

-A flat drop with impact on the top

After test, there is no electrical and mechanical damage permitted.

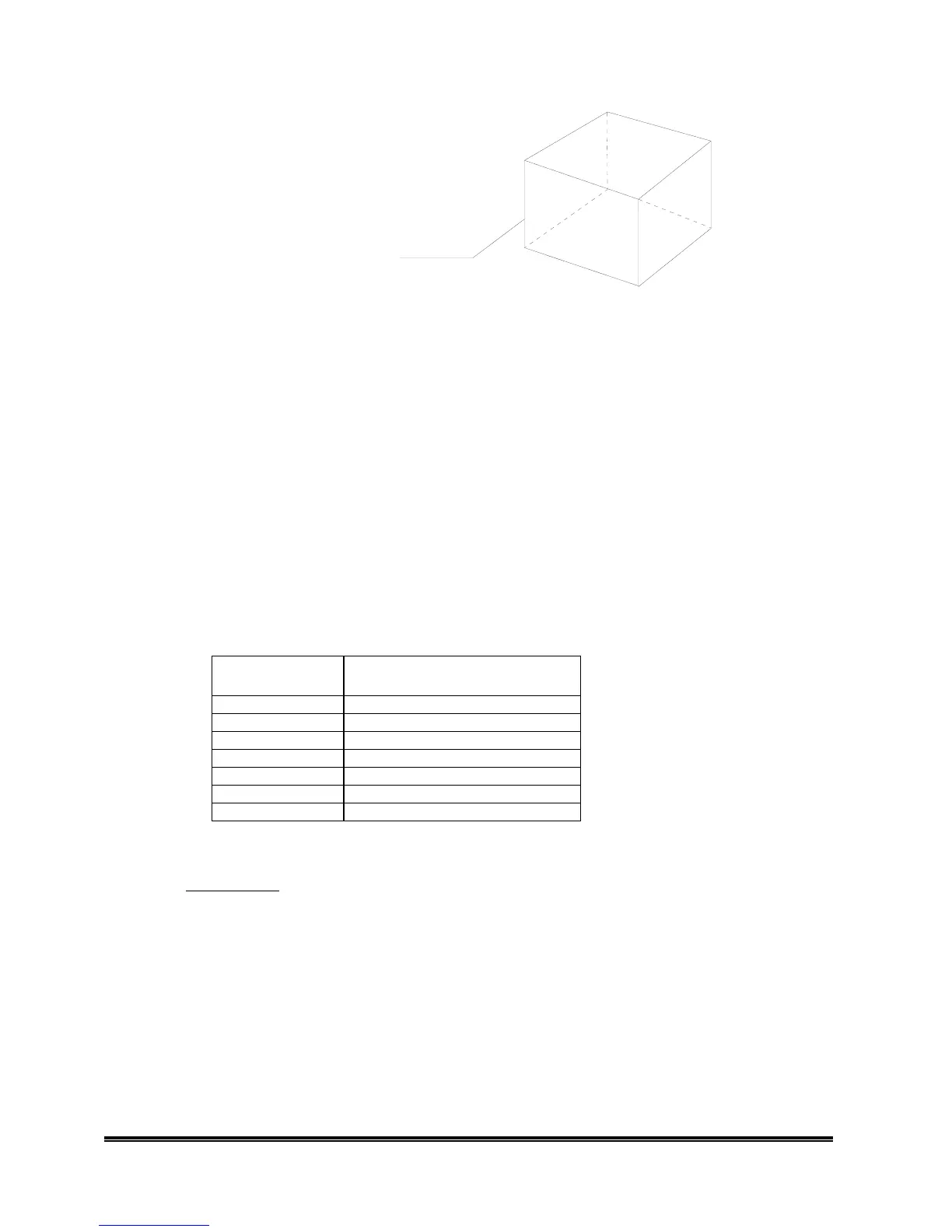

2.2.3 Vibration Test (Unpackaged, Non-Operating)

5~200Hz at 1.04g rms

FREQUENCY (Hz) SPECTRUM LEVEL (g

2

/Hz)

2.0 0.0185

4.0 0.0300

8.0 0.0300

40.0 0.0030

55.0 0.0100

70.0 0.0100

200.0 0.0010

DURATION: 15 MINUTES PER AXIS.

2.2.4 HALF-SINE SHOCK

Test conditions:

Test unit : 2 sets

Each unit has to withstand 18 shocks.(3 shocks pre face)

No- operation

Half-sine wave

Duration : 3ms

Acceleration(G) : 75G

2.3 Packing Configuration

2.3.1 Container Specification

a. Shipping Container

Loading...

Loading...