- do not place it on a cooker or other cooking device

-donotleaveinammableproductsintheroomwheretheboileris

installed

- heatsensitivewalls(forexample,woodenwalls)mustbeprotected

with proper insulation.

IMPORTANT

Beforeinstallation,washeverysystempipingcarefullyinorderto

removeanyresiduesthatmayimpairtheoperationoftheappliance.

Underthesafetyvalve,installawatercollectingfunnelwiththe

corresponding discharge in the event of leaks due to the overpres-

sureoftheheatingsystem.Thedomestichotwatercircuitdoesnot

needasafetyvalve,butmakesurethatthepressureofwaterworks

does not exceed 6 bar. In case of doubts, install a pressure reducer.

Prior to ignition, make sure that the boiler is designed to operate

withthegasavailable;thiscanbecheckedbythemessageonthe

packagingandtheadhesivelabelindicatingthegastype.

Itisveryimportanttohighlightthatinsomecasesthesmokepipes

are under pressure and therefore, the connections of several ele-

ments must be airtight.

ANTI-FREEZE SYSTEM

Theboileristtedasstandardwithanautomaticanti-freezesystem

thatactivateswhenthetemperatureofthewaterintheprimary

circuitfallsbelow6°C.Thissystemisalwaysactive,guaranteeing

boiler protection to an outdoor temperature level of -3 °C. To take

advantageofthisprotection(basedonburneroperation),theboiler

mustbeabletoswitchitselfon;anylockoutcondition(e.g.lackof

gas/electricitysupply,orsafetydeviceintervention)thereforedeac-

tivates the protection.

Theanti-freezeprotectionisalsoactivewhentheboilerisonstandby.

In normal operation conditions, the boiler can protect itself against

freezing. If the machine is left unpowered for long periods in areas

wheretemperaturesmayfallbelow0°C,andyoudonotwantto

draintheheatingsystem,youareadvisedtoaddaspecic,good

qualityanti-freezeliquidtotheprimarycircuit.Carefullyfollowthe

manufacturer'sinstructionswithregardsnotonlythepercentageof

anti-freeze liquid to be used for the minimum temperature at which

youwantto keep the machine circuit, butalsothe duration and

disposal of the liquid itself.

Forthedomestichotwaterpart,werecommendyoudrainthecir-

cuit.Theboilercomponentmaterialsareresistanttoethyleneglycol

based anti-freeze liquids.

3.2 Securing the boiler to the wall and hydraulic connections

Tofastentheboilertothewall,usethecardboardtemplate(g.

4-5)inthepackaging.Thepositionandsizeofthehydrauliccon-

nections are indicated below:

A CHreturn 3/4”

B CHdelivery 3/4”

C gasconnection 3/4”

D DHWoutput 1/2”(forC.S.I.)-3/4”(forR.S.I.)

E DHWinput 1/2”(forC.S.I.)-3/4”(forR.S.I.)

IncaseofreplacementofBerettaboilersfromprevioustype,there

isanadaptationkitofhydraulicconnectionsavailable.

3.3 Electric connection

Theboilersleavethefactorycompletelywiredwiththepowercable

alreadyconnectedandtheyonlyneedtheconnectionoftheambient

thermostat(AT)tobecarriedoutinthespecicterminals.

To access the terminal board:

-turnoffthesystemgeneralswitch

-undothexingscrews(A)oftheshell(g.6)

- move forward and then upwards the shell base to unhook it from the

chassis

-undothexingscrews(B)oftheinstrumentpanel(g.7)

- turn the instrument panel upside down

-removetheterminalboardcover(g.8)

-insertthecableofthepossibleT.A.(g.9)

The ambient thermostat must be connected as indicated on the

wiring diagram.

Ambient thermostat input in safety low voltage (24 Vdc).

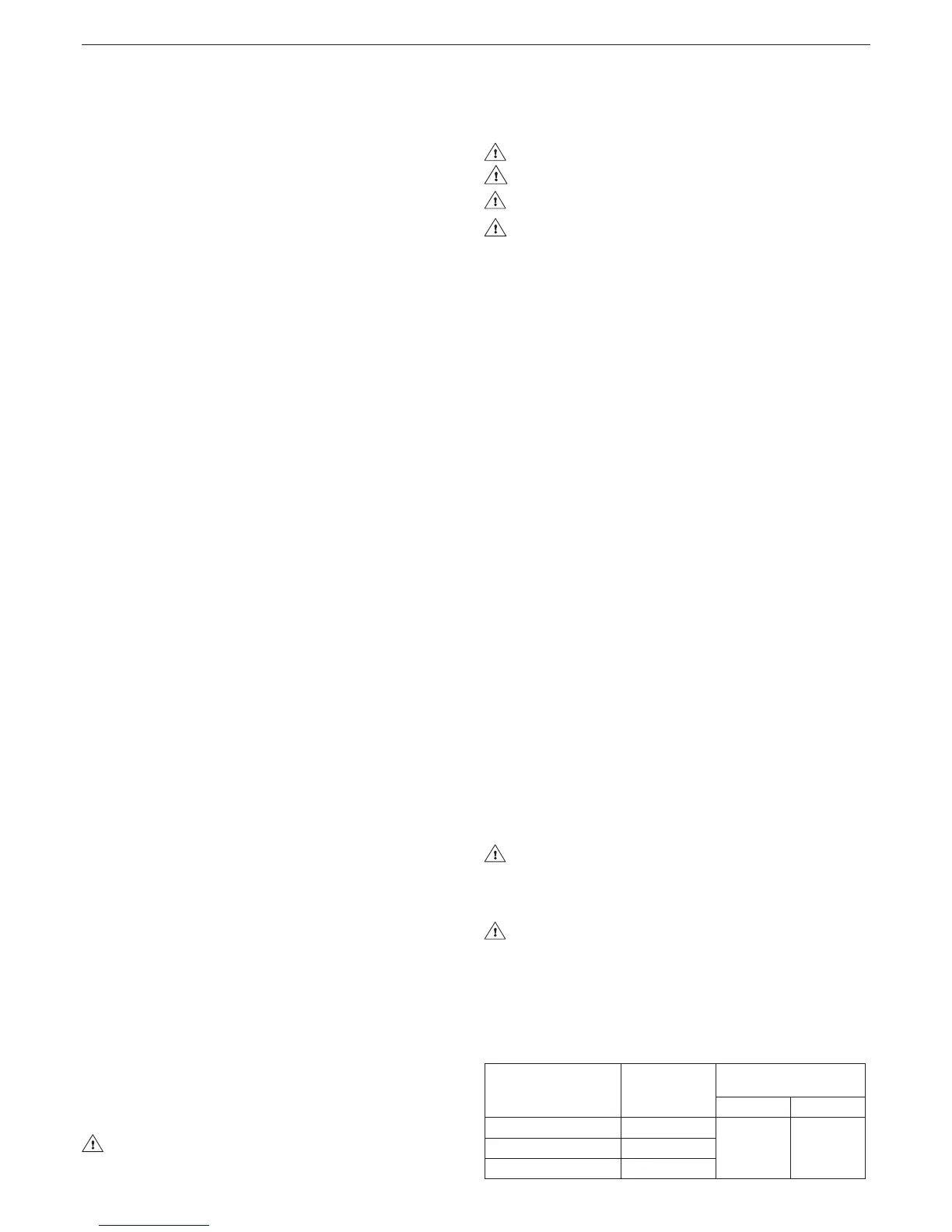

Pipe length

ø 80 [m]

Flue gas

ange (F)

Load losses for each

bend (m)

45° 90°

up to 1,5

Ø 39

1,2 1,7

from 1,5 to 5

Ø41(**)

from 5 to 14

Ø 43

20 C.S.I.

(**)ttedinboiler

Theconnectiontothemainssupplymustbecarriedoutthrougha

separationdevicewithanomnipolaropeningofatleast3.5mm(EN

60335-1,categoryIII).

The appliance operates with an alternating current of 230 Volt/50 Hz

and an electrical power of 100W for 20 C.S.I. - 115W for 24 C.S.I.

and24R.S.I.(andcomplieswiththestandardEN60335-1).

Itiscompulsorytocarryoutconnectionwithanefcientearth

circuit, according to national and local legislation.

Itisadvisabletocomplywithneutralphaseconnection(L-N).

The earth wire must be a couple of centimetres longer than the

others.

Do not use gas and/or water pipes to earth electrical ap-

pliance.

Themanufacturerdeclinesliabilityforanydamageiftheappliance

was not connected to an earth circuit.

Use the power cable supplied to connect the boiler to the mains power

supply.

If the power cable is replaced, use a cable type HAR H05V2V2-F,

3 x 0.75 mm

2

, with max. outside diameter 7 mm.

3.4 Gas connection

Before connecting the appliance to the gas network, check that:

- national and local regulations are complied

- thegastypeistheonesuitablefortheappliance

- the piping is clean.

The gas pipe must be installed outdoor. If the pipe goes through

the wall, it must go through the central opening, in the lower part

of the template.

Itisadvisabletoinstallalterofsuitabledimensionsonthegasline

if the distribution network had solid particles.

Once the appliance has been installed check that connections are

sealed according to current installation regulations

3.5 Fumes exhaustion and air suction

For fumes exhaustion, refer to the current local and national regula-

tions.AlwayscomplywithlocalstandardsoftheFireDepartment,

theGasCompanyandwithpossiblemunicipaldispositions.

Thereleaseofcombustionproductsisassuredbyacentrifugalfan

placed inside the combustion chamber and its correct operation

isconstantlycheckedbyapressureswitch.Theboilerissupplied

withouttheuegasoutlet/airsuctionkit,sinceitispossibletouse

the accessories for appliance with a forced draught sealed chamber

that better adapts to the installation characteristics.

Itisessentialforuegasreleaseandtherestorationofboilercom-

bustionairtousecertiedpipesandthatconnectioniscarriedout

correctlyasindicatedbytheinstructionssuppliedwiththeuegas

accessories.

Withonlyonesmokepipeyoucanconnectmorepiecesofappli-

anceprovidedthateverypieceofapplianceissealedchambertype.

“FORCED OPEN” INSTALLATION (TYPE B22P/B52P)

Fumes outlet duct Ø 80 mm (g. 10a)

The fumes outlet duct can be aimed in the most suitable direction for

installation needs. To install follow the instructions supplied with the kit.

Inthisconguration,theboilerisconnectedtotheØ80mm

fumesoutletductbymeansofaØ60-80mmadaptor.

In this case, the combustion supporting air is taken from the

room in which the boiler is installed, which must be a suitable

and ventilated technical room.

Non-insulated fumes outlet ducts are potential sources of

danger.

Whennecessary,theuegasange(F)mustberemovedusinga

screwdriver as a lever.

Theboilerautomaticallyadaptsventilationaccordingtothetypeof

installation and the length of the duct.

Loading...

Loading...