Electrical 7

Disconnect power before working on pump, motor, pressure switch, or wiring.

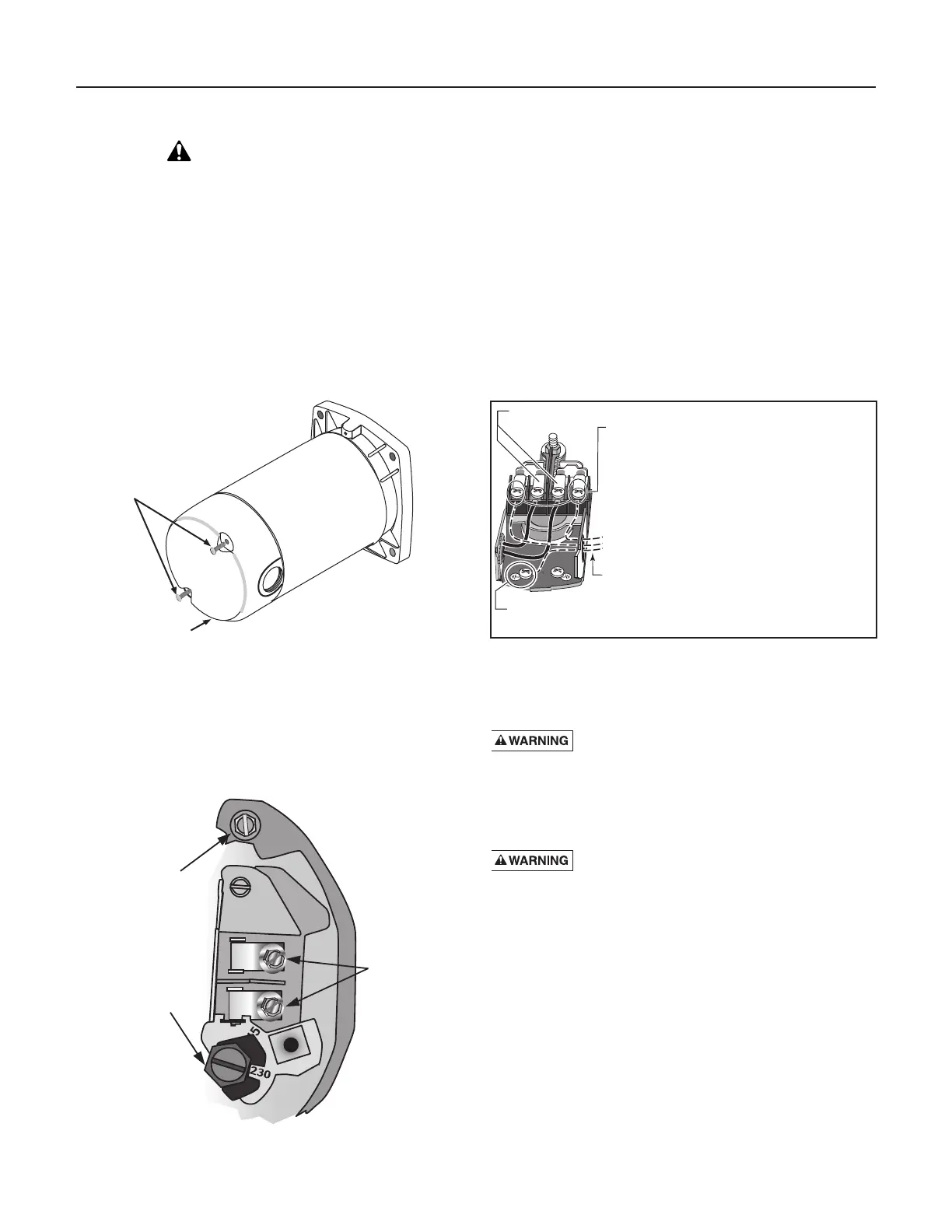

MOTOR SWITCH SETTINGS

Dual-voltage motors (motors that can operate at either

115 or 230 volts), are set at the factory to 230 volts. Do

not change motor voltage setting if line voltage is 230

volts, or if you have a single voltage motor.

NOTE: Never wire a 115 volt motor to a 230 volt line.

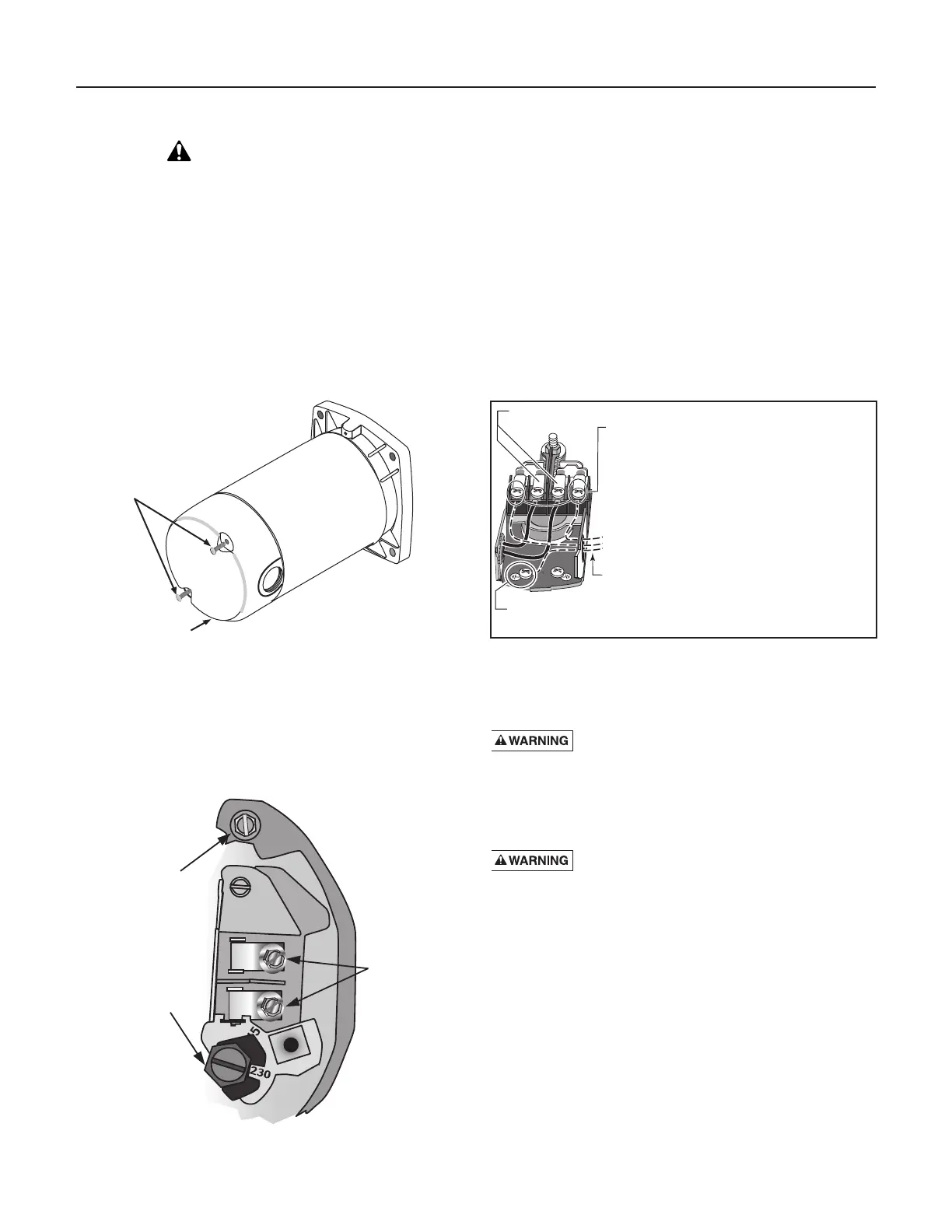

Remove Motor End Cover

If you have a dual-voltage motor, and will connect it to

115 volts, follow the procedure below.

You will need to remove the motor end cover to change

the voltage setting.

Your motor terminal board (located under the motor end

cover) should look like that shown below.

To change to 115 volts:

Step 1. Make sure power is off.

Step 2. Turn the dial counter-clockwise until 115 shows

in the dial window.

Step 3. The wires from the pressure switch should

already be attached to to power lead terminals.

Step 4. Reinstall the Motor end cover.

Pressure Switch Wiring

Step 5. Go to Wiring Connections below.

Hazardous voltage. Can shock, burn, or

kill. Connect ground wire before connecting power sup-

ply wires. Use the wire size (including the ground wire)

specified in the wiring chart. If possible, connect the

pump to a separate branch circuit with no other appli-

ances on it.

Explosion hazard. Do not ground to a gas

supply line.

Figure 6: Removing Motor End Cover

on the terminal screws.

to the green ground screw.

here and cap the white (neutral) wire. It does

not matter which wire goes to which screw.

which one). Connect the white (neutral) wire

to the other screw. Cap any remaining

black or red wires.

Loading...

Loading...