22

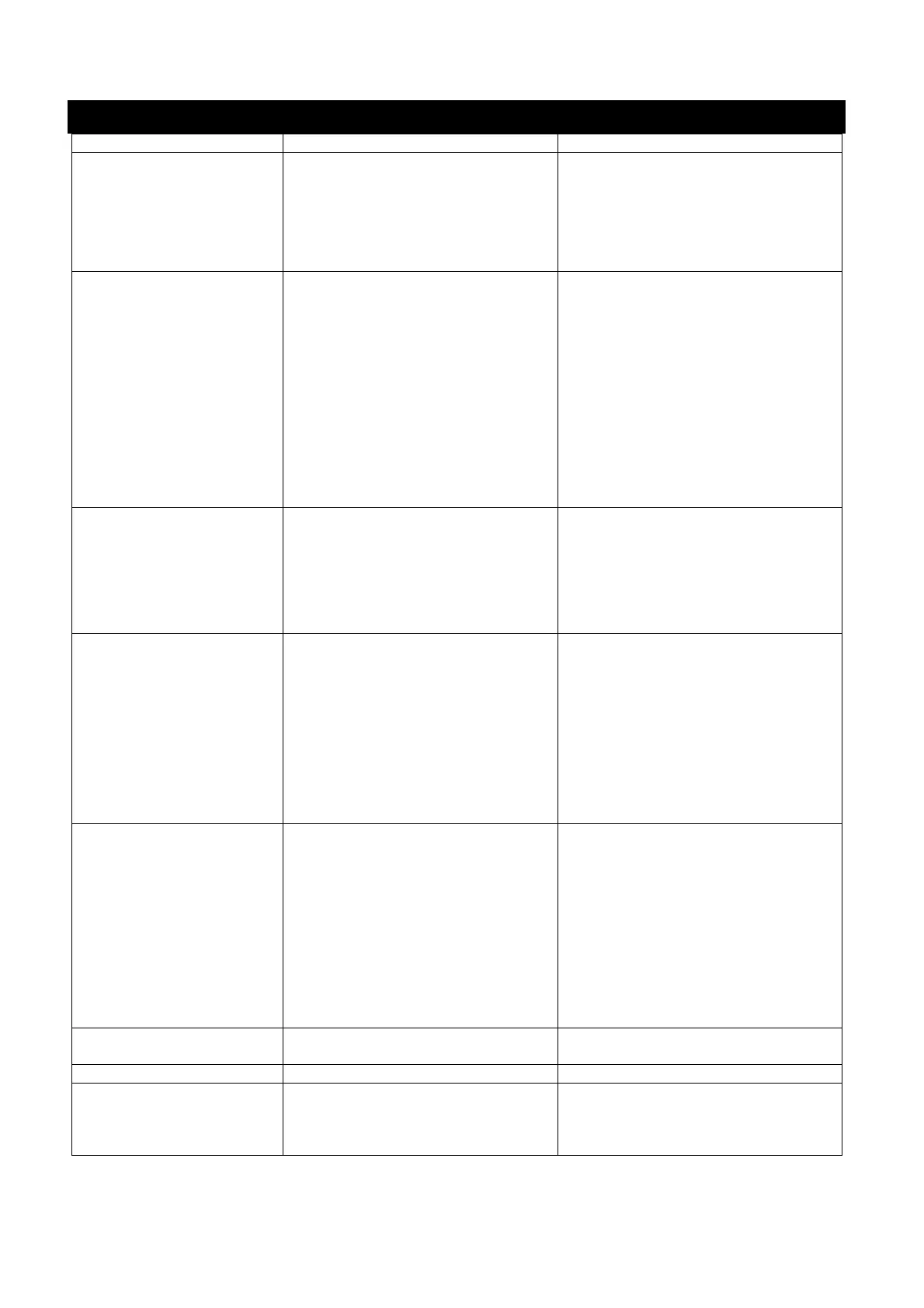

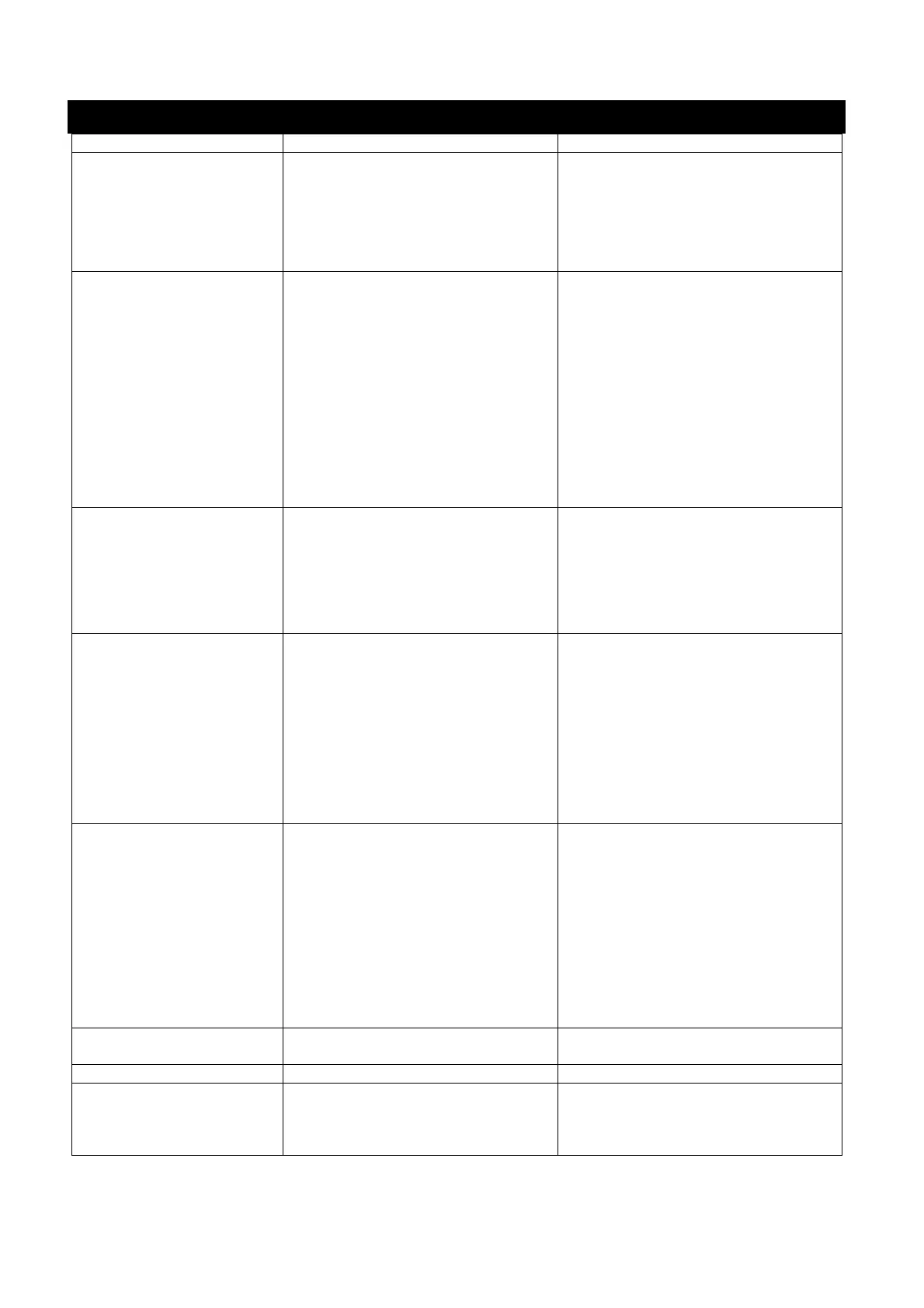

8- TROUBLESHOOTING

FAULT CAUSE REMEDY

When starting the pump does

not supply water and does not

make any noise

Not enough water capacity in the inlet

circuit

Blocked valves

The outlet line is closed and does not al-

low the air in the head to come out

Check the circuit and water level in the

reservoir.

Check and replace if necessary.

Drain the outlet line until the water regu-

larly comes out

The pump is noisy and beats

improperly

Pump is sucking air

Inlet circuit of improper size

Jammed or worn valves

Worn high pressure seals

Malfunctioning of the pressure regulator

Problems with driving

The number of revolutions is higher than

the value indicated on the label

Check suction circuit and possible air in-

gress

Check the correct size of the inlet circuit.

Check the filter cleaning

Check and if necessary replace

Check alignment, gaps, calibration.

Restore the proper number of revolutions

Vibrations or strokes on the

pipeline

Air intake

Malfunctioning of the pressure regulator

The pressure regulator by-pass line is un-

dersized or obstructed

Blocked valves

Check the suction circuit and possible

air ingress

Check and if necessary replace.

Check the correct sizes

Check and/or replace if necessary..

The pump normally runs, but

does not achieve the indicated

performance

Inlet circuit of improper size

Malfunctioning or not adjusted pressure

regulator

Nozzle of improper size or worn

Worn plunger seals

Worn check valves

The number of revolutions is lower than

the value indicated on the label

Check the correct size of the inlet circuit.

Check the filter cleaning

Check and/or replace if necessary

Restore the proper number of revolutions

The pump is noisy and over-

heat

Excessive temperature of liquid

The working pressure is higher than the

one indicated in the label

The number of revolutions is higher than

the value indicated on the label

Excessive strain of the belts

Oil not at its level, contaminated or ex-

hausted

Worn bearings

Reduce the water temperature

Restore the proper values

Check, fill or change if necessary.

Replace

Water dripping below the

pump

Worn Packings

Worn 0-Ring plunger retainer

Check and/or replace

Check and/or replace

Oil dripping

Worn Oil seal Check and/or replace

The pressure gauge shows ir-

regular oscillations at high

pressure with open lance

Valve with impurities

Worn Plunger seal

Worn Check valves

Clean the valve and lubricate the parts with

grease

Check and/or replace

Check and/or replace

CAUTION!: nozzle is subject to wear, to be replaced every time your pump will not reach the required pres-

sure; in fact, when worn, enlarging the size of the water hole, the actual flow rate increases and pressure de-

creases.

Loading...

Loading...