29 / 49

➢ Influence on cutting quality from over high gas pressure

a. Too large air flow makes cutting surface relatively coarse and cutting seam wider.

b. Too large air flow causes melting to the cutting part, and influences cutting quality.

6.6.2 Influence on piercing from auxiliary gas

1) Laser can’t easily cut through cutting board when gas pressure is too low, thus piercing time

shall increase, which leads to low production rate.

2) The breakthrough point can be melted down with popping occurred when gas pressure is too

high. Thus, larger melting point is formed, which influences the cutting quality.

3) During laser piercing, generally higher gas pressure is adopted for thin plate piercing and

lower gas pressure is adopted for thick plate piercing.

4) In the case of cutting ordinary carbon steel with laser cutting machine, the thicker the material

the lower the cutting gas pressure will be.

6.7 Laser power

Laser power has decisive influence on cutting process and quality.

a) Too small power cannot realize cutting

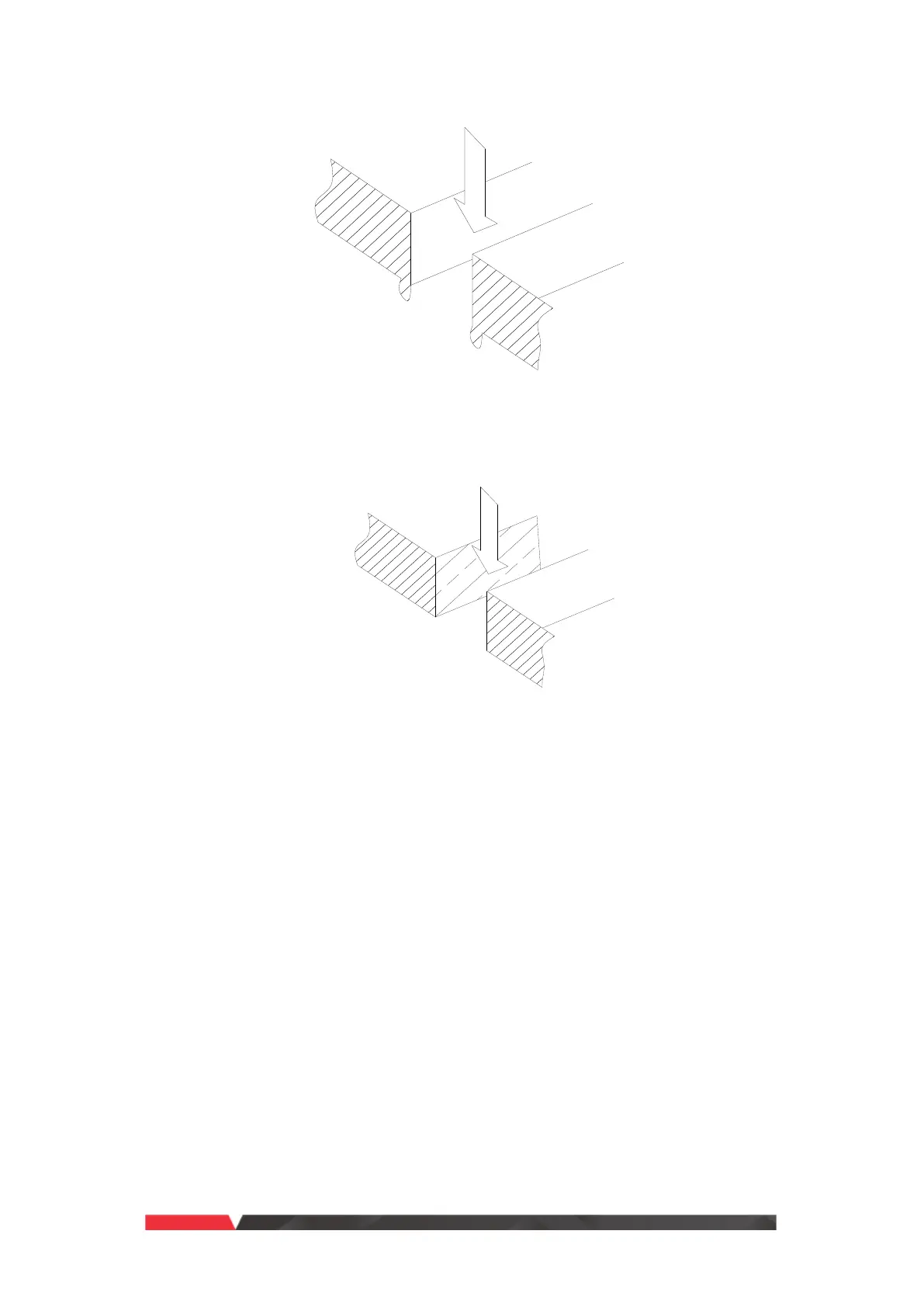

Loading...

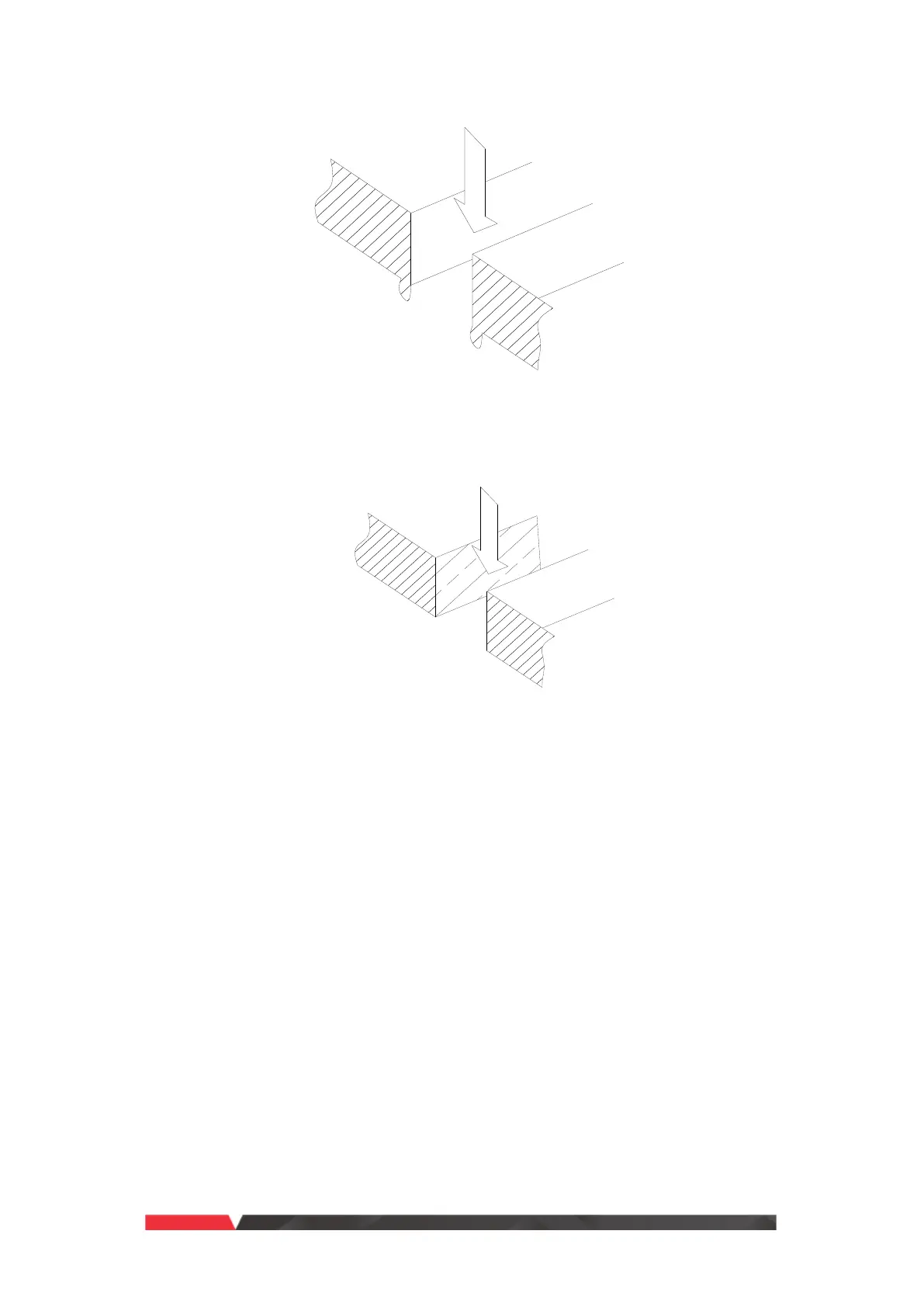

Loading...