17 / 49

Equipment debugging

After installation, the equipment needs debugging and processing test. Equipment debugging

mainly completes state detection of each module of the machine, including motion module, laser

module and electrical I/O module.

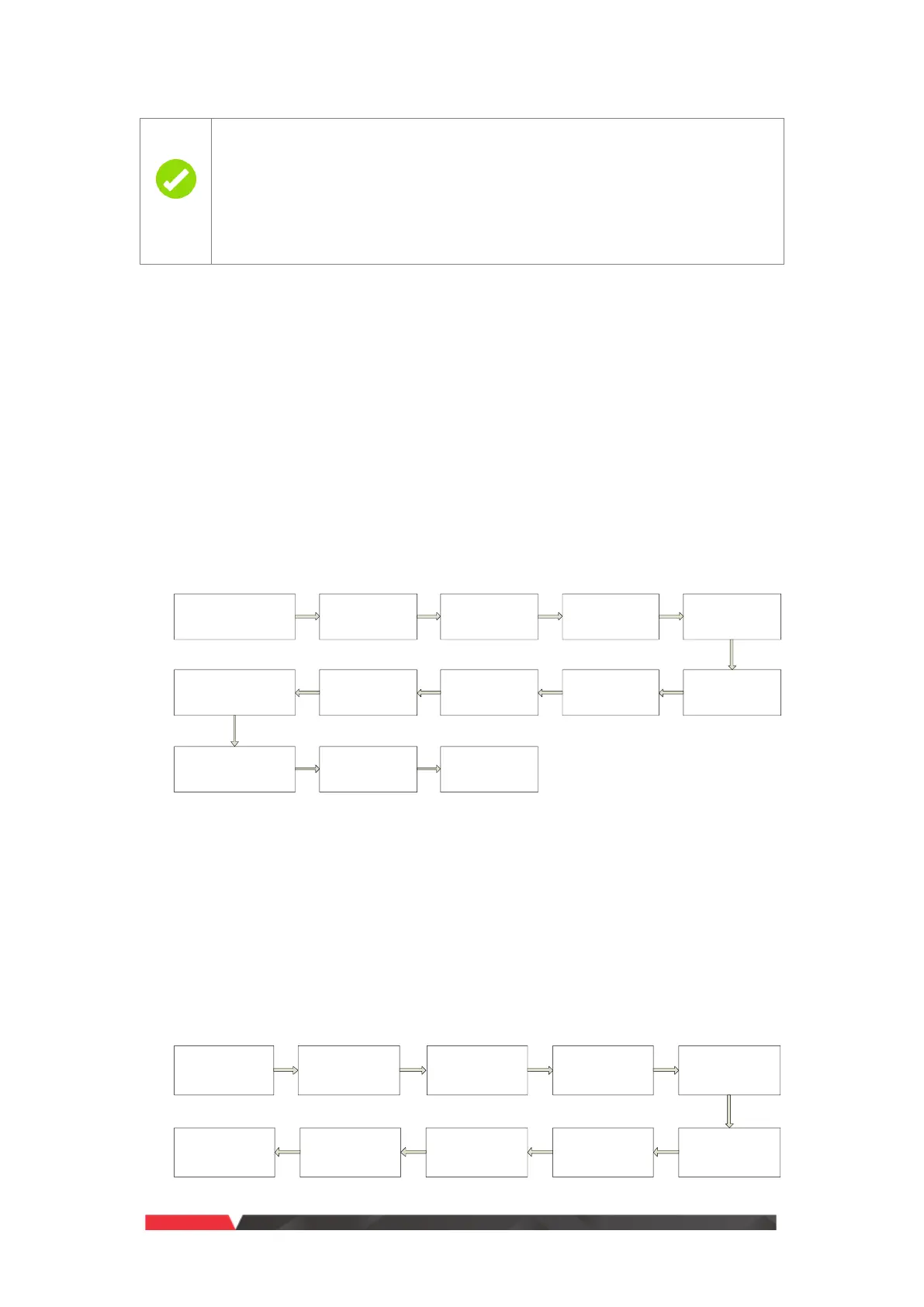

Switching sequence

Switching on sequence

Open gas source

valve

Turn on main

power switch

Turn on key

switch (Lock)

Turn on the

power (Power

On)

Turn on the

chiller

Execute Follower

First

Turn on laser

power

Check the size of

nozzle gas

Machine home

Start cutting

software

Tighten ceramic

ring

Tighten nozzle

Start cutting

Reminder:

➢ Execute Follower First after replacing materials of different thickness every time!

➢ After turn off the machine, please ensure no high pressure air sealed in the air pipe,

otherwise, the air pipe may be broken by the high pressure air, leak the high pressure

air please.

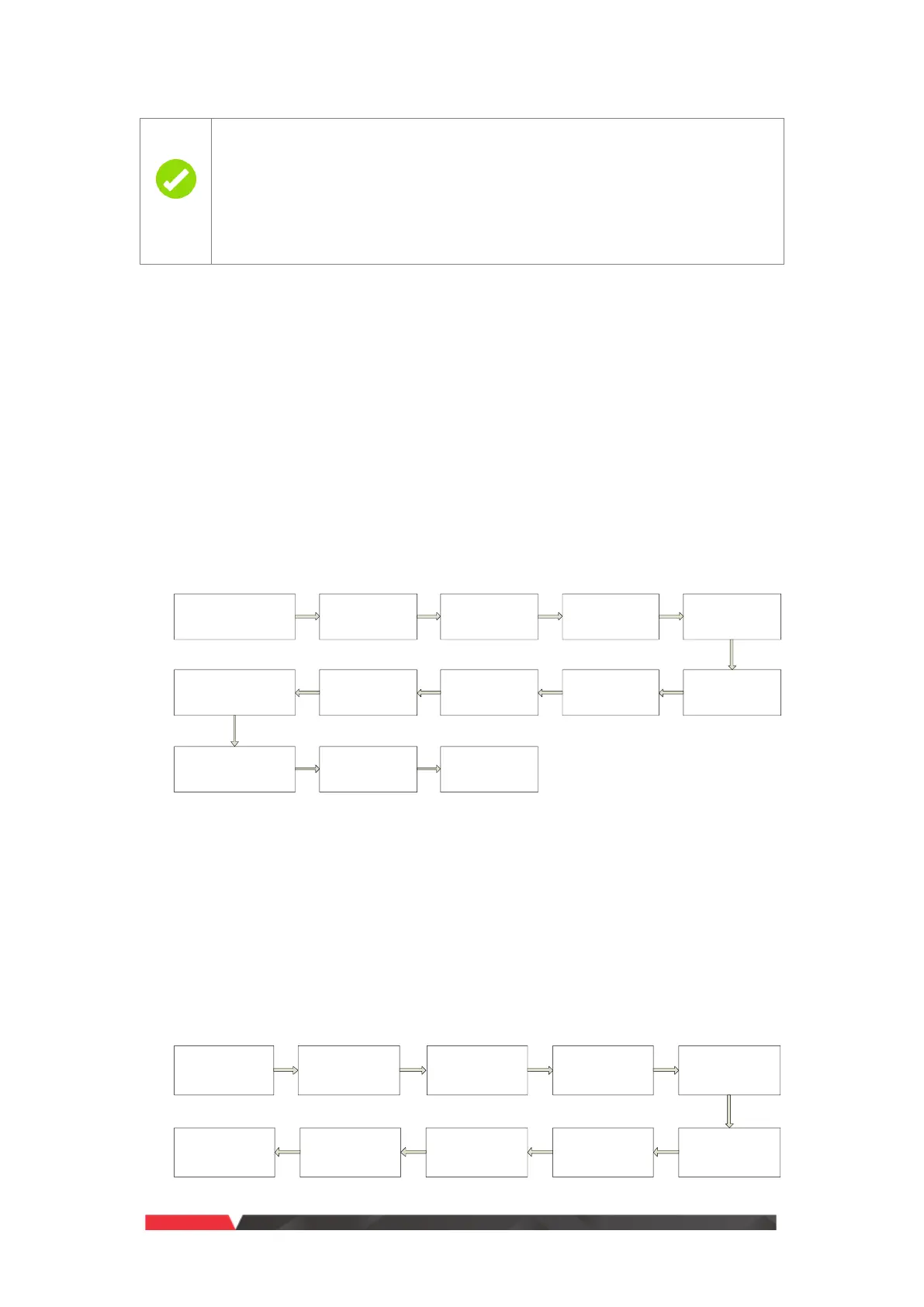

Switching off sequence

Drain away the

water form air

compressor

Close the gas

valve

Shut down the

laser generator

power

Turn off the

chiller

Machine home

Turn off the key

switch

Shut down the

computer

Close the

software

Turn off the

general power

Exhaust the gas

pipeline

When the emergency is eliminated, rotate the emergency stop button clockwise

to reset it naturally and release the emergency stop state;

Other buttons are available only after the key switch is activated;

Cylinder lift button is only used for loading and unloading;

Cylinder lift is jointly controlled by the cylinder lift button and in-position sensor,

and the cylinder rises only when both are effective.

Loading...

Loading...