3

CHECKS AND MAINTENANCE

53

GB

NOTE

Failure to successfully complete the above procedure can be the result of an improp-

erly sized idling jet.

a) If the mixture adjusting screw is turned until it stops and no changes in the idle

speed are observed, a smaller idling jet is required.

b) If the engine stalls when the adjusting screw is still two turns open, a larger idling

jet is needed.

Naturally, after replacing the jet the adjusting procedure will have to be restarted

from the beginning.

•Turn the adjusting wheel until you obtain the desired idle speed.

•The idle speed will have to be adjusted again in case of marked changes in the

outside temperature and riding altitude.

CARBURETTOR WEAR GUIDELINES

The throttle valve, the needle valve and the needle jet are subject to heavy wear

due to engine vibrations.

This can result in carburettor malfunctions (e.g. mixture enrichment).

CHECKING THE FLOAT LEVEL

(fl oat height)

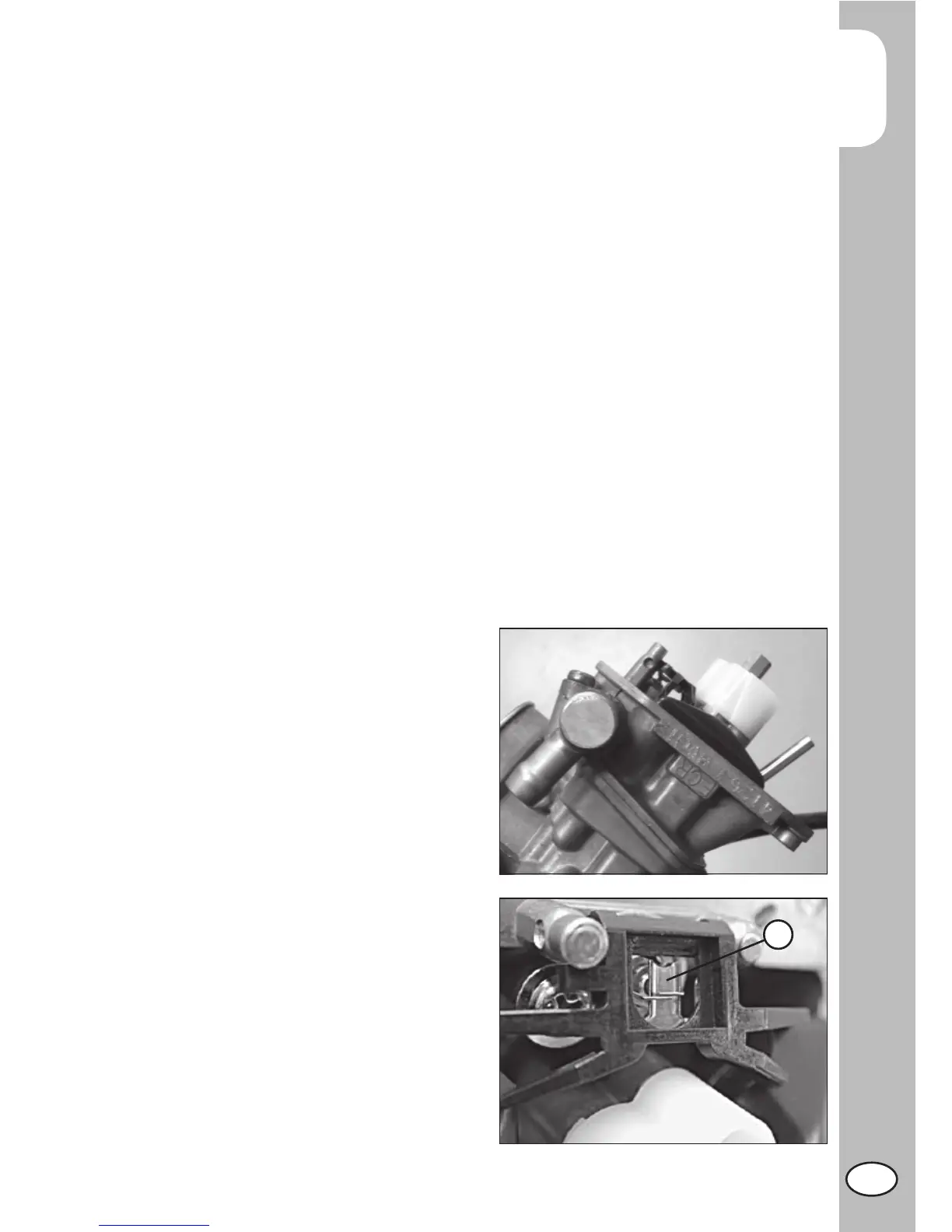

Remove the carburettor and the float

chamber. Tilt the carburettor so that the

fl oat touches the fl oat needle valve without

pressing it too hard.

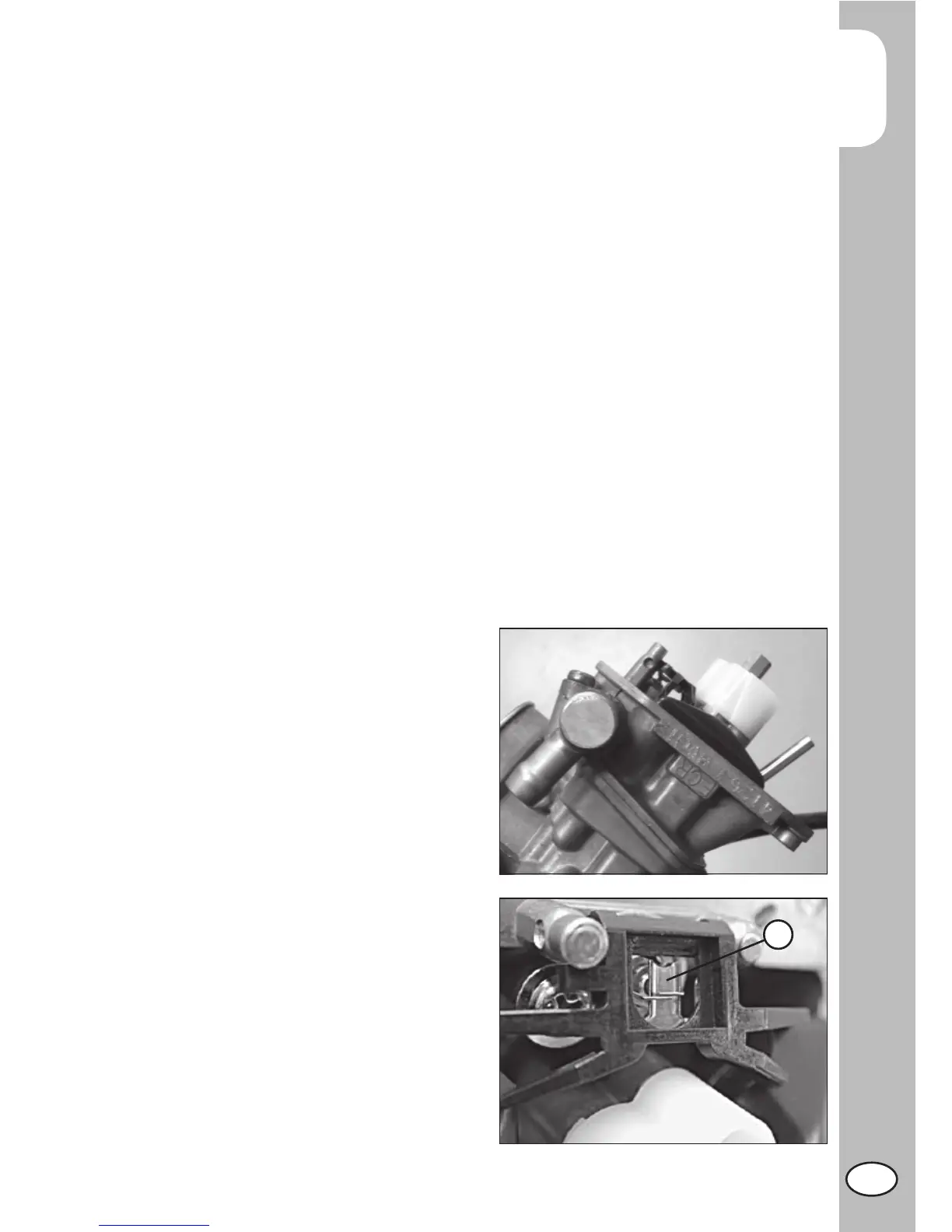

In this position the fl oat edge should be

parallel with the fl oat chamber sealing

surface (see fi gure).

If the fl oat height does not correspond to

the nominal value, check the fl oat needle

valve and if necessary replace it.

If the needle valve is in working order,

adjust the fl oat height by bending fl oat

lever 3.

Fit the fl oat chamber, install the carburettor

and adjust the idle speed.

3

Loading...

Loading...