MAINTENANCE & TROUBLESHOOTING16

TECH SUPPORT U.S. TOLL FREE: 877-995-8155 / INT'L: +1-561-995-8155

DISCONNECT POWER AND BATTERIES BEFORE PERFORMING ANY MAINTENANCE OR REPAIR TO THE

ACTUATORS

MAINTENANCE - Inspect the screw-drive gears for lubrication, debris and cleanness at least once a year. For

actuators installed in areas where dirt and dust are a concern, maintenance should be done at shorter intervals.

Keep the screw-drive lubricated using BFT grease I101115. Do not apply grease if gears are dirty. If necessary,

clean with solvent before applying.

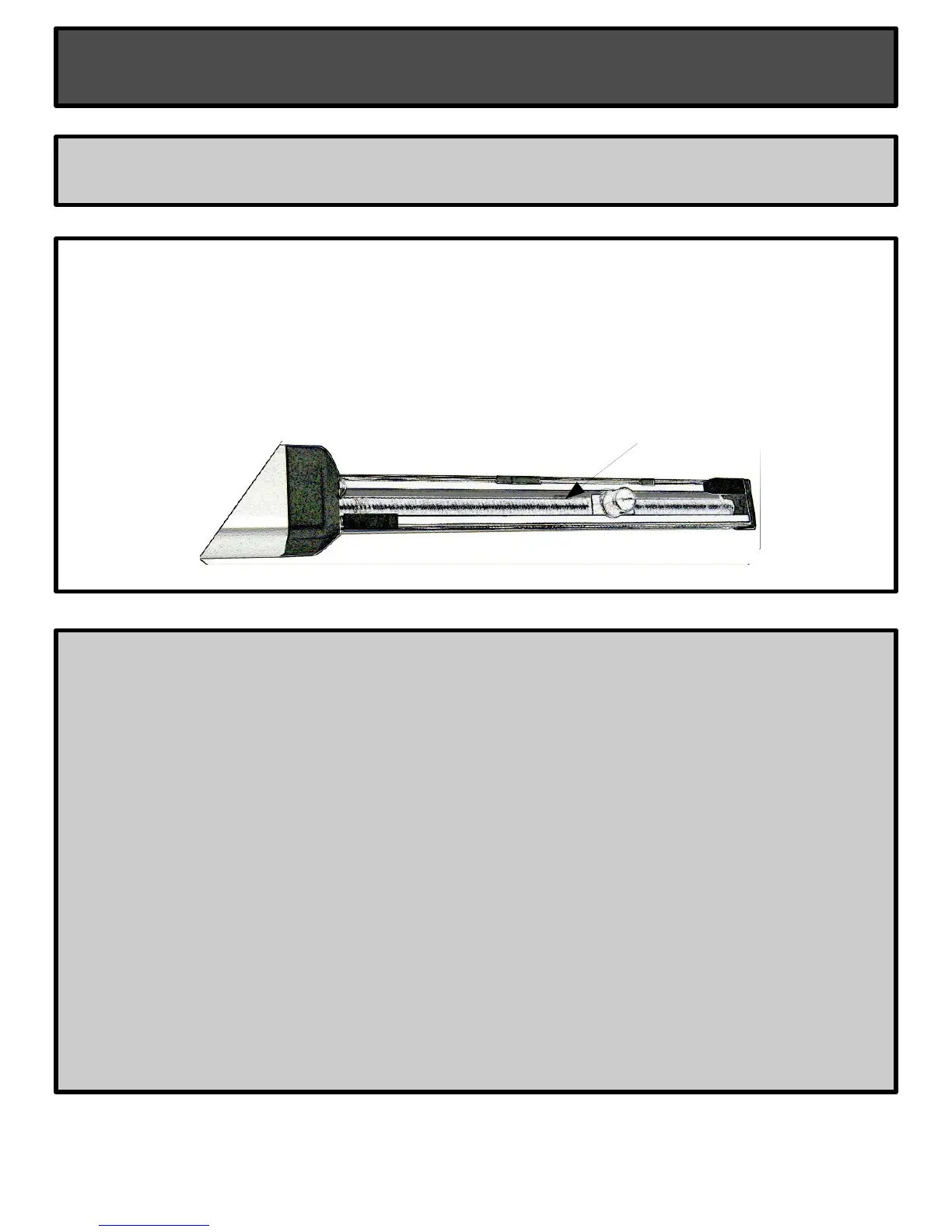

PHOBOS UNDERSIDE

SCREW-DRIVE

TROUBLESHOOTING

SYSTEM DOES NOT TURN ON.

●

Check incoming power. You should have 120 vac at the Line In terminal block in the controller enclosure.

●

Check transformer power. You should measure close to 31 VAC between the transformer's tabs labeled 0V and

25V. If no voltage is present, replace primary fuse on the Line In terminal block with a 1.25 Amp, slow-blow fuse.

●

Check secondary fuse on the controller board. Replace with 2 Amp, slow-blow fuse if needed.

SYSTEM IS ON BUT MOTOR DOES NOT RUN.

●

Verify motor wiring. Page 10.

●

Reset UL Block by triggering the stop circuit. Page 12.

MOTOR RUNS BUT IT DOES NOT STOP.

●

Make sure that the magnet holder is in place. Page 7.

●

Inspect the limit switch adjustment. Page 9.

●

Verify motor wiring. Page 10.

GATE STOPS DURING THE OPENING CYCLE.

●

Verify that the PHOTO input is not being triggered. To defeat the PHOTO input during the open cycle see page 15.

Loading...

Loading...