INSTALLATION MANUAL

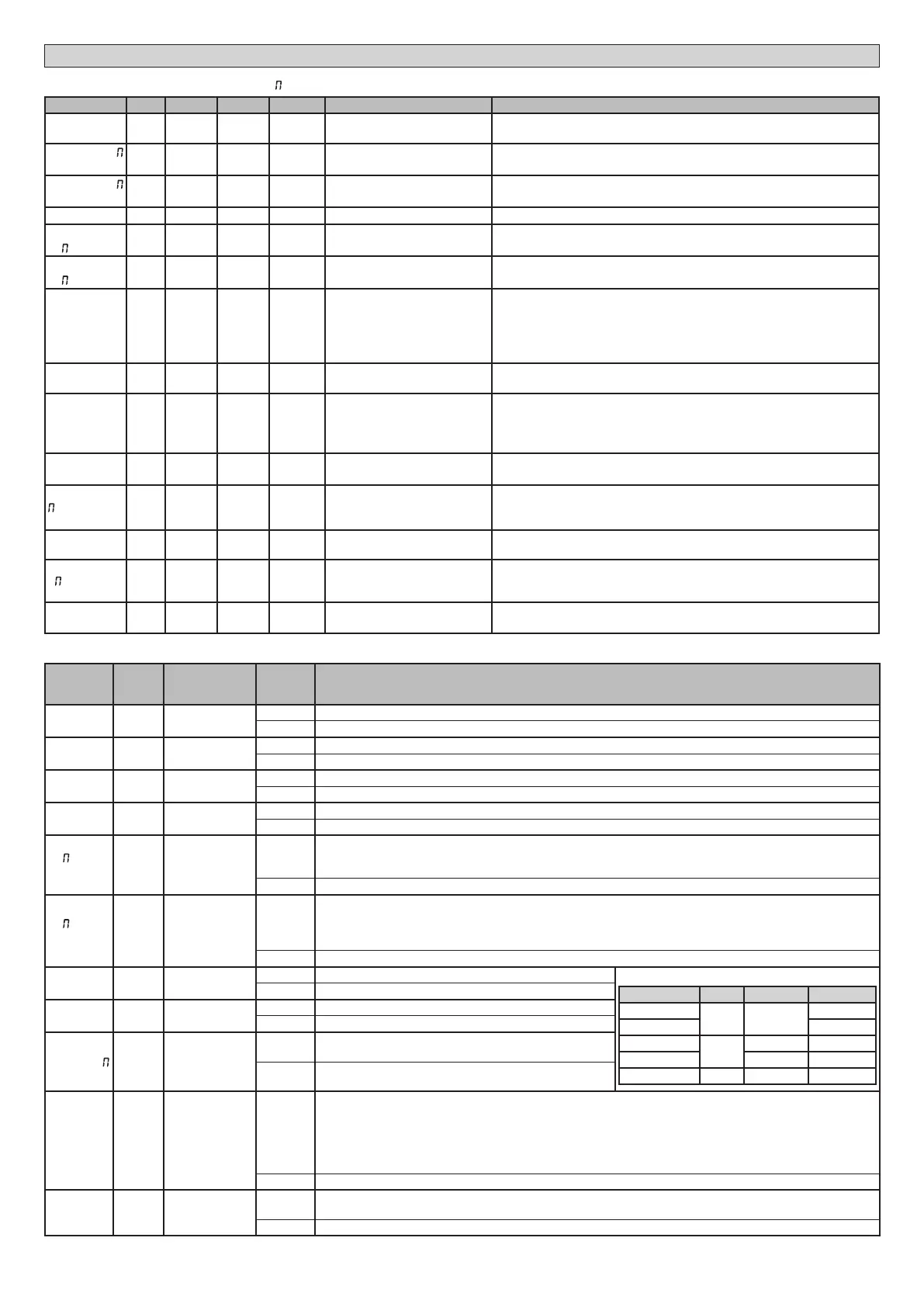

10.1 TABLE A: PARAMETERS MENU PARA

Parameter min. max. default personal Denition Description

TCA

3 sec. 120 sec. 40 Automatic Closing Time

Set the numerical value of the TCA automatic closing time from 3 to 120

seconds.

vork. t.

ot.1

3 sec. 180 sec. 60 Operation time motor 1

Enter the numerical value corresponding to the working time from 3 to 180

seconds for motor 1.

vork. t.

ot.2

3 sec. 180 sec. 60 Operation time motor 2

Enter the numerical value corresponding to the working time from 3 to 180

seconds for motor 2.

ped. t.

3 sec. 9 sec. 6 Pedestrian operation time

Set the pedestrian opening time of motor 2 from 3 to 90 seconds.

open delay

ti

e

0 sec. 10 sec. 3 Opening delay time for leaf 1

Set the opening delay time for motor 1 with respect to motor 2, which can

be adjusted from 0 to 10 seconds.

c l s de l ay

ti

e

0 sec. 60 sec. 3 Closing delay time for leaf 2

Set the closing delay time for motor 2, which can be adjusted from 0 to

60 seconds.

slov -

dovn t.

0 sec. 20 sec. 0 Slow-down time

Set the slow-down to approach time from 0 to 20 seconds. The slow-down

time is subtracted from the work time.

NOTE: it is advised to activate timing.

NOTE: only use this function when limit switches are tted.

NOTE: Do not use with hydraulic motors.

clear. t

0 sec. 30 sec. 15

Traffic-light area clearance

time

Set the required clearance time for the area involved in the trac governed

by trac light, from 0 to 30 seconds. Set to 0 if not used.

preheat.

0% 99% 30% Preheating

Set the percentage value of the current from 0 (deactivated pre-heating) to

99% which can be made to pass through the motor windings to keep them

at the right temperature.

NOTE: Only with SSR5.

slovd

torque

1% 99% 50% Slowdown Motor Torque

Set numerically from 1% to 99% the value of motor torque during slowdown

time.

ot. torque

1% 99% 50% Motor torque

Set the numerical torque value from 1 to 99%.

NOTE: When using with oil-hydraulic motors, it is necessary to set the

torque value to 99% and adjust the force directly on the motor.

brake

0% 99% 0% Braking

Set the braking value from 0% (min.) to 99% (max.) according to the gate

weight and the mechanical demands involved.

e

er. brake

0% 99% 60% Emergency braking

Set the value of the emergency braking from 0% (min.) to 99% (max.). This

is carried out by enabling the safety commands on the inputs 34 (block),

37 (SAFE OP) and 55 (SAFE CL).

Zone

0 127 0 Zona

Enter the zone number between 0 (minimum value) and 127 (maximum

value). See paragraph “SCS OPTIONAL MODULES”.

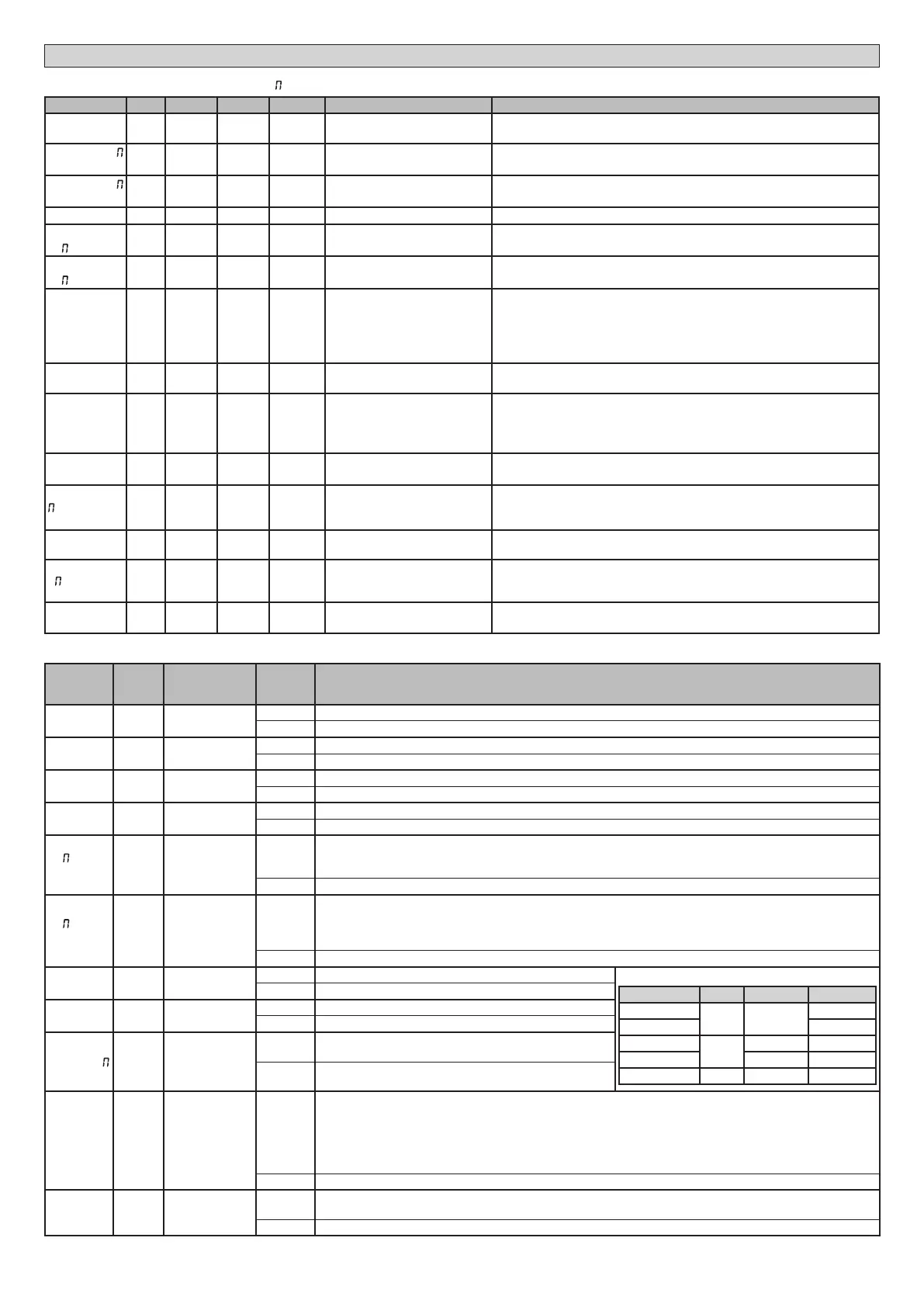

10.2 TABLE B: LOGIC MENU logic

Logic Default Denition

Cross out

setting

used

Description

TCA

OFF

Automatic

Closing Time

ON Switches automatic closing on.

OFF Switches automatic closing o.

Ibl open

OFF

Opening Impul-

se lock

ON The Start impulse has no eect during the opening phase.

OFF The Start impulse becomes eective during the opening phase.

ibl TCA

OFF

Impulse lock

TCA

ON The Start impulse has no eect during the TCA dwell period.

OFF The Start impulse becomes eective during the TCA dwell period.

bl close

OFF

Impulse lock on

closing

ON The start impulse has no eect during the closing stage.

OFF The start impulse is eective during the closing stage.

ra

blov

c.op

OFF

Ram blow on

opening

ON

It pushes for approx. 2 seconds in closing direction before opening. This allows the electric lock to be released

more easily (not aected by limit switches). IMPORTANT - When no adequate mechanical backstops are

installed, do not use this function. It is also to be absolutely avoided in the automation of sliding gates.

OFF Excludes the ram blow in closing.

ra

blov

c.cl

OFF

Ra m blow in

closing

ON

Before carrying out the closing manoeuvre, the gate pushes for about 2 seconds on opening. This allows the

electric lock to be released more easily.(not aected by limit switches)

IMPORTANT - When no adequate mechanical backstops are installed, do not use this function. It is also to be

absolutely avoided in the automation of sliding gates.

OFF Excludes the ram blow in closing.

2 step

OFF

2-step, 4-step

logic

ON Enables 2-step logic (prevails over “3-step logic”).

A start impulse has the following eects:

2 step 3 step 4 step

closed

opens opens

opens

on closing stop

open

closes

closes closes

on opening stop + TCA stop + TCA

after stopping closes opens opens

OFF Enables 4-step logic when the 3-step logic is set to OFF.

3 step

OFF 3-step logic

ON Enables 3-step logic (with 2 steps=OFF).

OFF Disables 3-step logic.

pre-alar

OFF Pre alarm

ON

The blinker comes on about 3 seconds before the motor

starts.

OFF

The blinker comes on at the same time as the motor

starts.

bloc

persist

OFF Lock hold

ON

If the motors remain still in a totally open or closed position for over one hour, they are activated for about 3

seconds in the respective direction. This operation takes place once every hour.

N.B.: This function has the purpose of compensating any oil volume decrease in the hydraulic motors, due to

a temperature drop during prolonged pauses, for instance at night, or to internal leaks.

IMPORTANT - When no adequate mechanical backstops are installed, do not use this function. It is also to be

absolutely avoided in the automation of sliding gates.

OFF Exclude block maintenance.

hold-to-

run

OFF Hold-to-run

ON

Hold-to-run operation: the manoeuvre continues as long as the command key is kept pressed.

IMPORTANT - It is not possible to use the radio transmitter.

OFF Impulse operation.

22 - RIGEL 5

D811472 00100_01

Loading...

Loading...