D812939 00096_03

VIRGO SMART BT A - 43

ENGLISH

INSTALLATION MANUAL

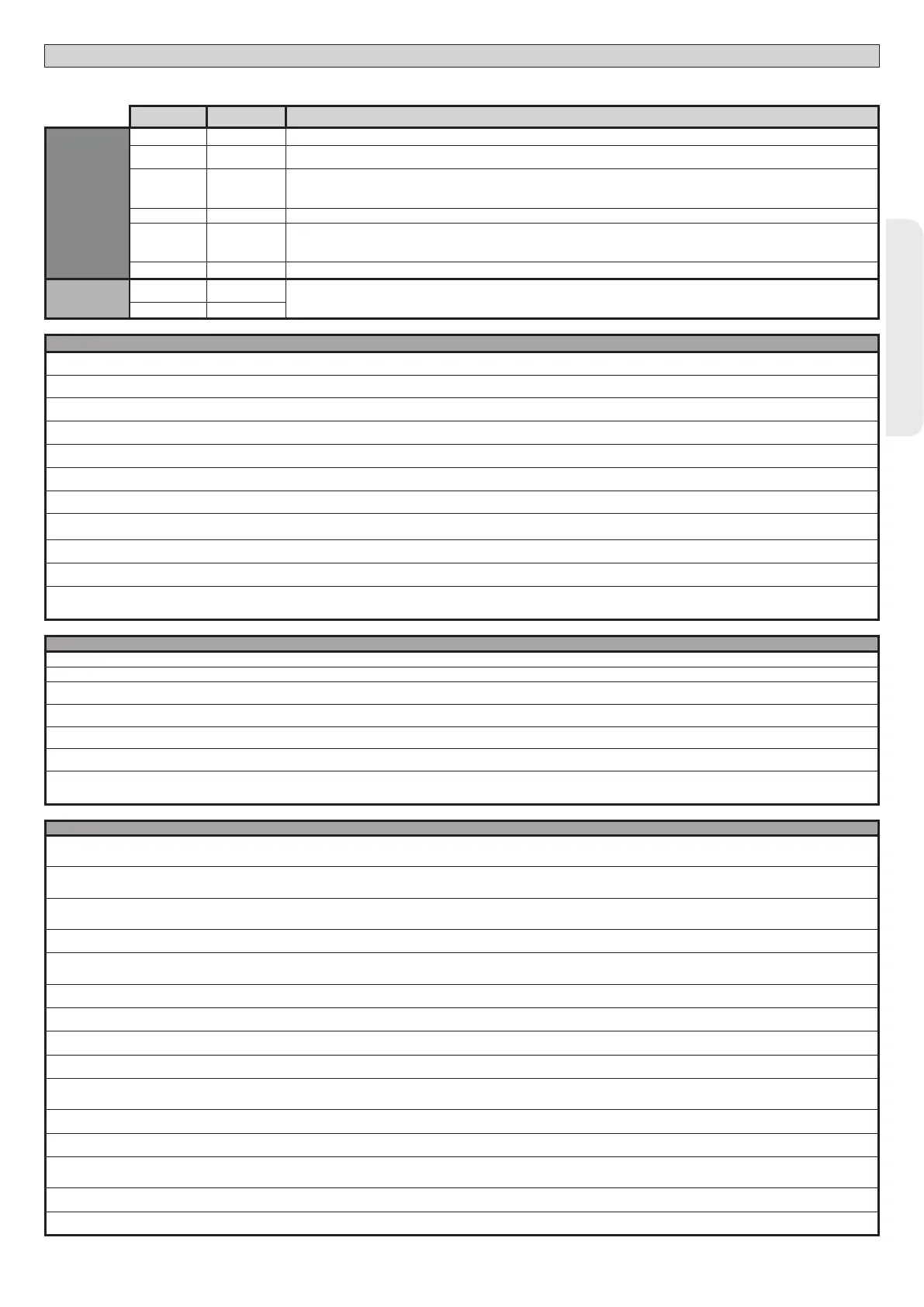

Terminal Denition Description

Safety devices

70 Common STOP, SAFE 1 and SAFE 2 inputs common

71 STOP

The command stops movement. (N.C.)

If not used, leave jumper inserted.

72 SAFE 1

Congurable safety input 1 (N.C.) - Default PHOT.

PHOT / PHOT TEST / PHOT OP / PHOT OP TEST / PHOT CL / PHOT CL TEST / BAR / BAR TEST / BAR 8K2 /

BAR OP / BAR OP TEST / BAR

8K2 OP/ BAR CL / BAR CL TEST / BAR 8K2 CL

Refer to the “Safety input conguration” table.

73 FAULT 1 Test input for safety devices connected to SAFE 1.

74 SAFE 2

Congurable safety input 2 (N.C.) - Default BAR.

PHOT / PHOT TEST / PHOT OP / PHOT OP TEST / PHOT CL / PHOT CL TEST / BAR / BAR TEST / BAR 8K2 /

BAR OP / BAR OP TEST / BAR

8K2 OP/ BAR CL / BAR CL TEST / BAR 8K2 CL

Refer to the “Safety input conguration” table.

75 FAULT 2 Test input for safety devices connected to SAFE 2.

Antenna

Y ANTENNA

Antenna input.

Use an antenna tuned to 433MHz. Use RG58 coax cable to connect the Antenna and Receiver. Metal bodies close to the antenna

can interfere with radio reception. If the transmitter’s range is limited, move the antenna to a more suitable position.

# SHIELD

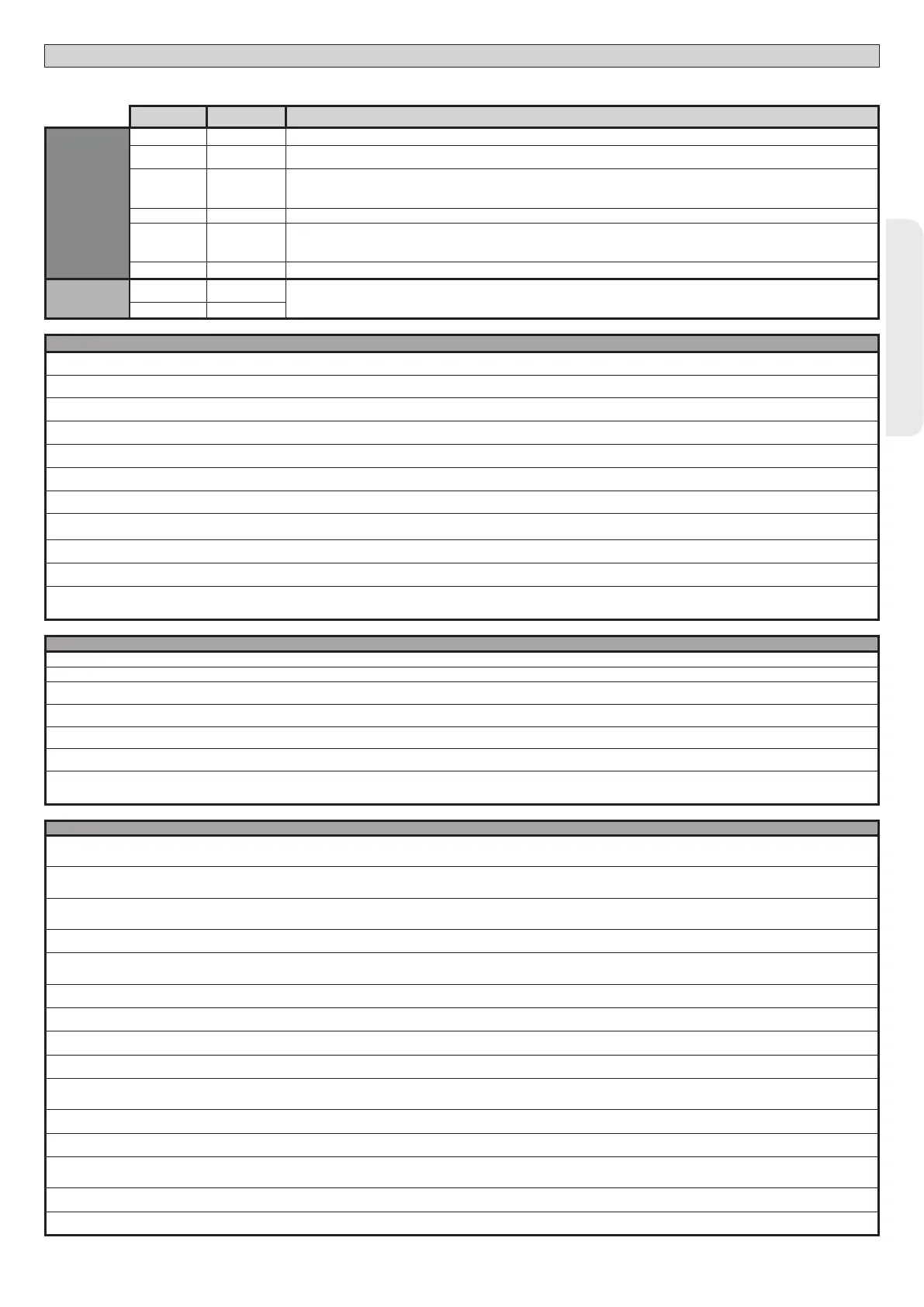

AUX output conguration

Aux logic= 0 - 2ND RADIO CHANNEL output.

Contact stays closed for 1s when 2nd radio channel is activated.

Aux logic= 1 - SCA GATE OPEN LIGHToutput.

Contact stays closed during opening and with leaf open, intermittent during closing, open with leaf closed.

Aux logic= 2 - COURTESY LIGHT command output.

Contact stays on for 90 seconds after the last operation.

Aux logic= 3 - ZONE LIGHT command output.

Contact stays closed for the full duration of operation.

Aux logic= 4 - STAIR LIGHT output.

Contact stays closed for 1 second at start of operation.

Aux logic= 5 - GATE OPEN ALARM output.

Contact stays closed if the leaf stays open for double the set TCA time.

Aux logic= 6 - FLASHING LIGHT output.

Contact stays closed while leaves are operating.

Aux logic= 7 - SOLENOID LATCH output.

Contact stays closed for 2 seconds each time gate is opened.

Aux logic= 8 - MAGNETIC LOCK output.

Contact stays closed while gate is closed.

Aux logic= 9 - MAINTENANCE output.

Contact stays closed once the value set for the Maintenance parameter is reached, to report that maintenance is required.

Aux logic= 10 - FLASHING LIGHT AND MAINTENANCE output.

Contact stays closed while leaves are operating. If the value set for the Maintenance parameter is reached, once the gate has nished moving and the leaf is closed, the contact closes for 10 sec. and

opens for 5 sec. 4 times to report that maintenance is required.

Command input conguration

IC logic= 0 - Input congured as Start E. Operation according to STEP-BY-STEP MOV. logic. External start for trac light control.

IC logic= 1 - Input congured as Start I. Operation according to STEP-BY-STEP MOV. logic. Internal start for trac light control.

IC logic= 2 - Input congured as Open.

The command causes the leaves to open. If the input stays closed, the leaves stay open until the contact is opened. When the contact is open, the automated device closes following the TCA time, where activated.

IC logic= 3 - Input congured as Closed.

The command causes the leaves to close.

IC logic= 4 - Input congured as Ped.

The command causes the leaf to open to the pedestrian (partial) opening position. Operation according to STEP-BY-STEP. logic

IC logic= 5 - Input congured as Timer.

Operation same as open except closing is guaranteed even after a mains power outage.

IC logic= 6 - Input congured as Timer Ped.

The command causes the leaf to open to the pedestrian (partial) opening position. If the input stays closed, the leaf stays open until the contact is opened. If the input stays closed and a Start E, Start I or Open

command is activated, a complete opening-closing cycle is performed before returning to the pedestrian opening position. Closing is guaranteed even after a mains power outage.

Safety input conguration

SAFE logic= 0 - Input congured as Phot (photocell) non tested (*). (g.M, ref.1).

Enables connection of devices not equipped with supplementary test contacts. When beam is broken, photocells are active during both opening and closing. When beam is broken during closing, movement is

reversed only once the photocell is cleared. If not used, leave jumper inserted.

SAFE logic= 1 - Input congured as Phot test (tested photocell). (g.M, ref.2).

Switches photocell testing on at start of operation. When beam is broken, photocells are active during both opening and closing. When beam is broken during closing, movement is reversed only once the

photocell is cleared.

SAFE logic= 2 - Input congured as Phot op (photocell active during opening only) non tested (*). (g.M, ref.1).

Enables connection of devices not equipped with supplementary test contacts. In the event beam is broken, photocell operation is disabled during closing. During opening, stops motion for as long as the

photocell beam stays broken. If not used, leave jumper inserted.

SAFE logic= 3 - Input congured as Phot op test (tested photocell active during opening only (

g.M

, ref.2).

Switches photocell testing on at start of operation. In the event beam is broken, photocell operation is disabled during closing. During opening, stops motion for as long as the photocell beam stays broken.

SAFE logic= 4 - Input congured as Phot cl (photocell active during closing only) non tested (*). (g.M, ref.1).

Enables connection of devices not equipped with supplementary test contacts. In the event beam is broken, photocell operation is disabled during opening. During closing, movement is reversed immediately. If

not used, leave jumper inserted.

SAFE logic= 5 - Input congured as Phot cl test (tested photocell active during closing only (g.M, ref.2).

Switches photocell testing on at start of operation. In the event beam is broken, photocell operation is disabled during opening. During closing, movement is reversed immediately.

SAFE logic= 6 - Input congured as Bar (safety edge) non tested (*). (g.M, ref.3).

Enables connection of devices not equipped with supplementary test contacts. The command reverses movement for 2 sec.. If not used, leave jumper inserted.

SAFE logic= 7 - Input congured as Bar (tested safety edge (g.M, ref.4).

Switches safety edge testing on at start of operation. The command reverses movement for 2 sec.

SAFE logic= 8 - Input congured as Bar 8k2 (g.M, ref.5). Input for resistive edge 8K2.

The command reverses movement for 2 sec.

SAFE logic=9 Input congured as Bar op, safety edge with active inversion only while opening, if activated while closing, the automation stops (STOP) (

g.M

, ref. 3).

Allows connecting devices not tted with supplementary test contact. The operation while opening causes the movement to be reversed for 2 seconds, the operation while closing causes the automation to stop. If not used,

leave jumper inserted.

SAFE logic=10 Input congured as Bar op test, safety edge checked with active inversion only while opening, if activated while closing, the automation stops (STOP) (

g.M

, ref. 4).

Activates testing safety edges when starting operation. The operation while opening causes the movement to be reversed for 2 seconds, the operation while closing causes the automation to stop.

SAFE logic=11 Input congured as Bar 8k2 op, 8k2 safety edge with active inversion only while opening, if activated while closing, the automation stops (STOP) (

g.M

, ref. 5).

The operation while opening causes the movement to be reversed for 2 seconds, the operation while closing causes the automation to stop.

SAFE logic=12 Input congured as Bar cl, safety edge with active inversion only while closing, if activated while opening, the automation stops (STOP) (g.M, ref. 3).

Allows connecting devices not tted with supplementary test contact. The operation while closing causes the movement to be reversed for 2 seconds, the operation while opening causes the automation to stop. If

not used, leave jumper inserted.

SAFE logic=13 Input congured as Bar cl test, safety edge checked with active inversion only while closing, if activated while opening, the automation stops (STOP) (

g.M

, ref. 4).

Activates testing safety edges when starting operation. The operation while closing causes the movement to be reversed for 2 seconds, the operation while opening causes the automation to stop.

SAFE logic=14 Input congured as Bar 8k2 cl, safety edge with active inversion only while closing, if activated while opening, the automation stops (STOP) (g.M, ref. 5).

The operation while closing causes the movement to be reversed for 2 seconds, the operation while opening causes the automation to stop.

(*) If “D” type devices are installed (as dened by EN12453), connect in unveried mode, foresee mandatory maintenance at least every six months.

Loading...

Loading...