MAINTENANCE

588/A page 11/24

NOTICE:

Blackmer compressor service and maintenance shall be performed by qualified technicians only. Service

and maintenance shall conform to all applicable local and national regulations and safety standards.

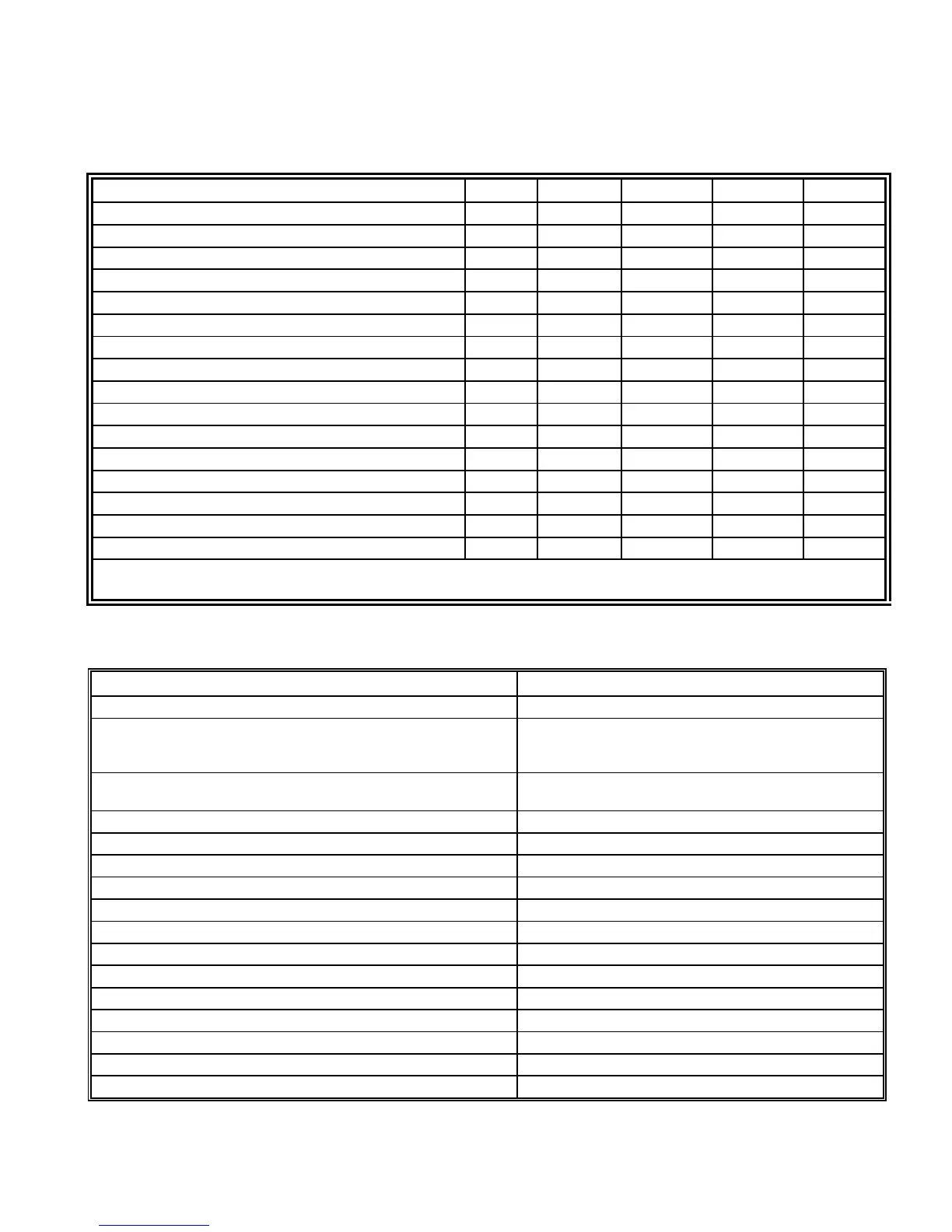

SERVICE SCHEDULE

Daily Weekly Monthly 6 Months Yearly

Overall Visual Check X

Check Crankcase Oil Pressure X

Check Suction Pressure X

Check Discharge Pressure X

Drain Distance Piece (Double-Seal Models) X

Drain Liquid From Accumulation Points X

Clean Compressor Cooling Fins X

Check Crankcase Oil Level * X*

Check Mounting and Anchor Bolts X

Check V-Belt Tension X

Change Oil and External Oil Filter * X*

Check Inlet Filter/Strainer Element X

Inspect Valves X

Lubricate 4-way Valve X

Lubricate Motor Bearings per Manufacturer's Suggestions X

Inspect Motor Starter Contact Points X

* Change oil every 1,000 hours of operation, or every 6 months which ever occurs first. If the oil becomes unusually dirty,

change oil and external filter as often as needed to maintain clean oil.

Table 5 - Service Schedule

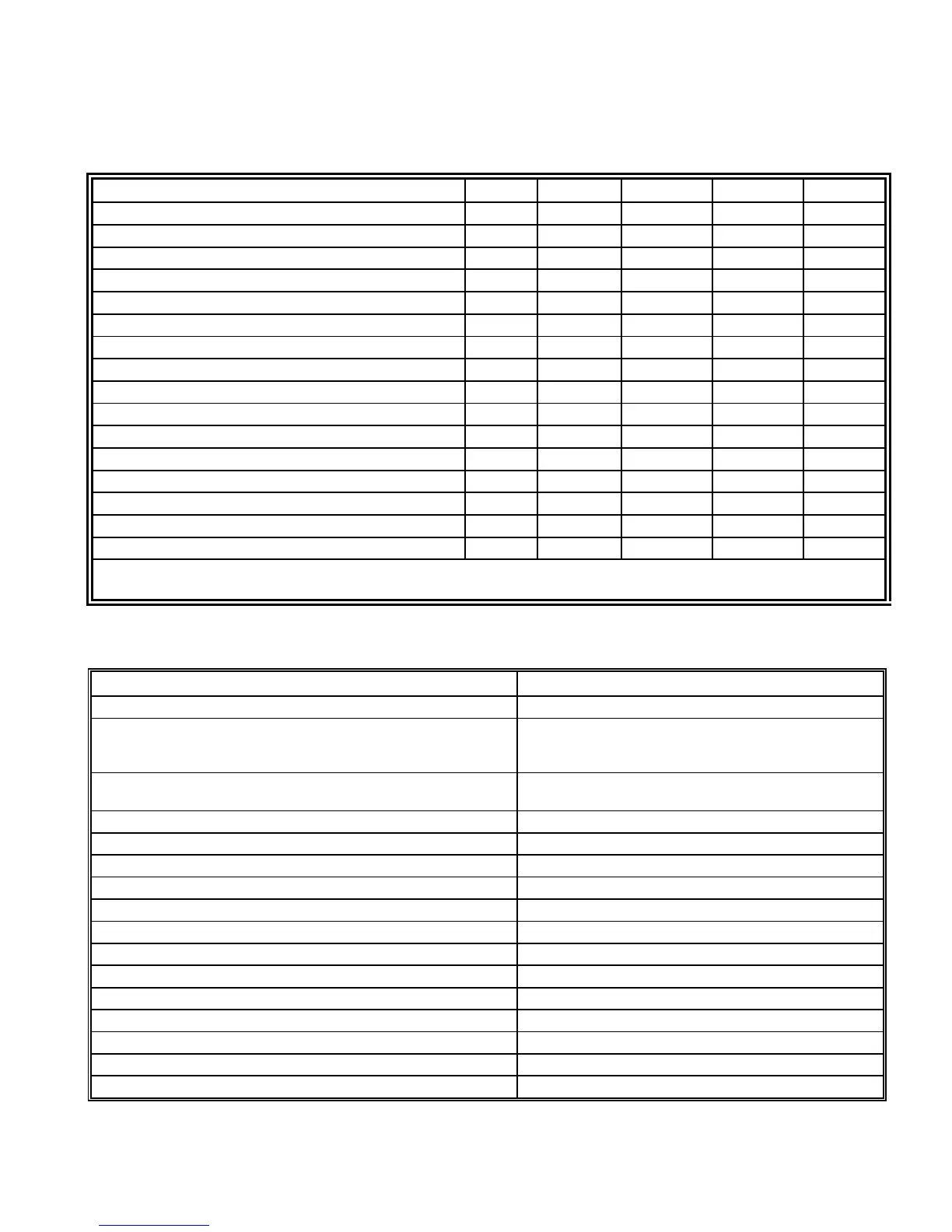

TOOL LIST

Description Used For:

Blackmer Wrench 790535 Valve Hold-down screw

Blackmer Packing Installation Tool

790536 for 160 and 360 Series Compressors

790538 for 600 Series Compressors

Rod-packing protection during installation.

3" Adjustable Spanner with 1/4" pins

(Blackmer PN 790316)

Piston Nut, Piston, Packing Box Hold-down Ring

9/16", 5/8" or 3/4" End Wrench Cylinder and Crosshead Guide

1-1/16" Wrench or Socket Valve Caps

Allen Wrenches: 3/16", 1/4", 3/8" Valves

Sockets: 7/16", 1/2", 9/16", 5/8", 3/4", 7/8" Various

Internal Snap Ring Pliers Seal Replacement

Feeler gauges or Depth Micrometer Piston Clearance

Screwdriver, Flat Blade Nameplate screws, Packing Installation

Pliers

Rubber Mallet

Arbor Press Wrist Pin Removal

Bearing Puller Crankshaft Bearings

Torque Wrench, 0 to 45 lb-ft range Various

Hoist (useful) Cylinder and Crosshead Guide

Table 6 - TOOL LIST

Loading...

Loading...