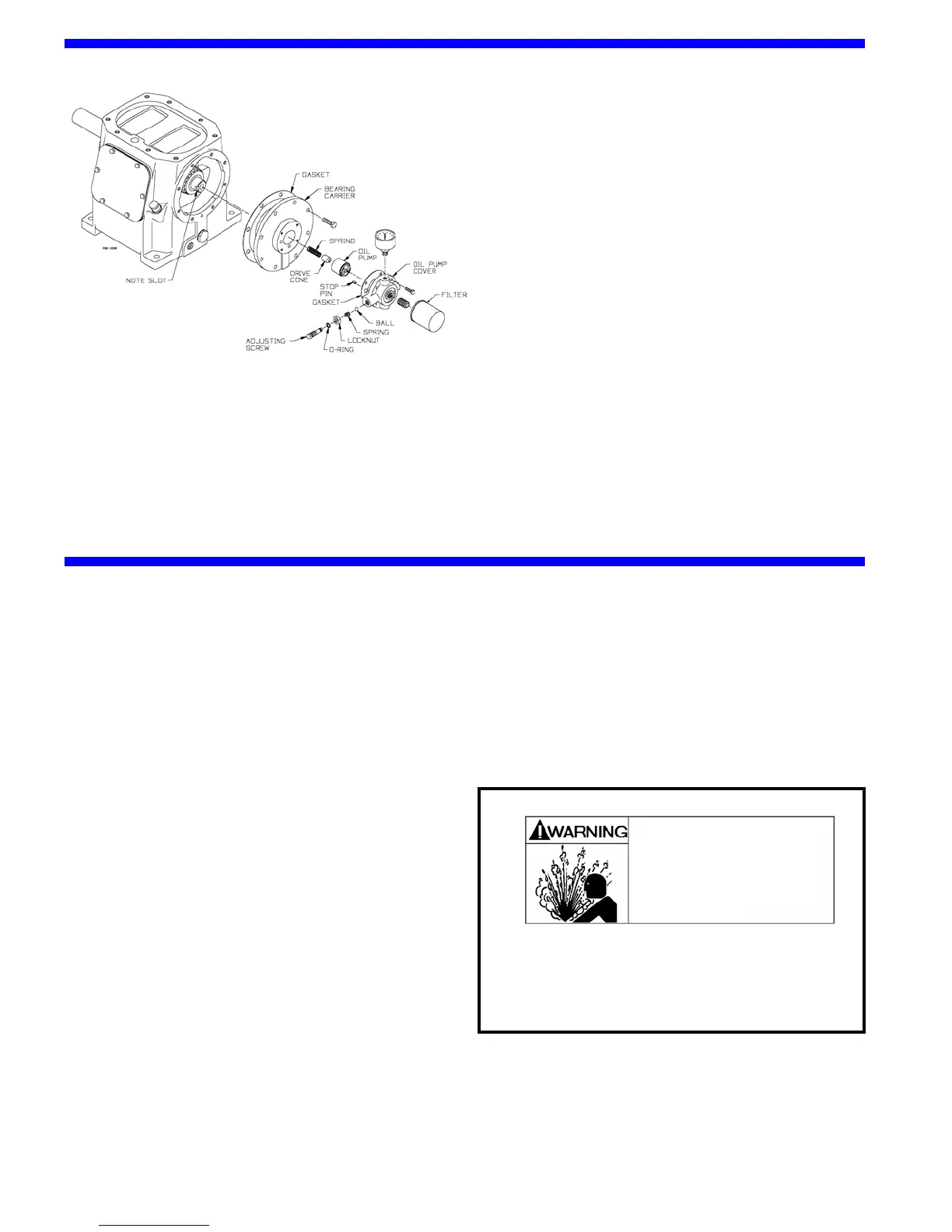

OIL PUMP REPLACEMENT

588/A page 20/24

Figure 15 – Oil Pump

1. Remove the oil pump cover bolts and oil pump

cover.

2. Remove the oil pump assembly, drive cone and

spring.

3. Clean and inspect parts for wear or damage,

replace as necessary.

4. Place the spring and the drive cone in the end of

the crankshaft.

5. Note the slot in the end of the crankshaft and the

drive tab on the back of the oil pump assembly.

Install the oil pump assembly into the bearing

carrier with the tab and slot aligned.

6. Note the groove around outer edge of the oil pump

assembly and the stop pin in the oil pump cover.

Position the oil pump cover and new gasket with

the pin in the oil pump groove, rotating the oil pump

as needed. The bolt hole positions ensure proper

orientation of the oil pump cover.

7. BY HAND, tighten the oil pump cover bolts while

the pump cover is held flush with the bearing

carrier.

NOTICE: If by hand tightening, the oil pump

cover cannot be drawn flush with the bearing

carrier, the drive tab or the stop pin are

improperly aligned. DO NOT WRENCH

TIGHTEN OR THE OIL PUMP WILL BE

DAMAGED.

8. Once the oil pump cover is secured by hand, the

bolts may be evenly tightened per Table 7 - "Bolt

Torque."

EXTENDED STORAGE PROCEDURES

If a compressor is not to be put into service for some

time, or if a compressor is to be taken out of service for

an extended period, the following procedures should be

taken.

1. Fill the crankcase with rust inhibiting oil. (New

compressors are shipped from the factory without

oil.) Squirt oil on the piston rods and crossheads

through the nameplate opening. Loosen the V-

belts to relieve the load on the bearings. Rotate the

compressor by hand a few times to distribute the

oil.

2. Plug all openings and purge the compressor with

an inert gas such as nitrogen or dry air at about 50

psig (3.5 bar-g). This may be done at the factory if

requested. Leave the compressor pressurized to

prevent air or moisture from entering the unit.

NOTICE: Tag the unit with a warning that it is

pressurized.

3. If a purge gas is not available, fog oil into the

compressor suction while rotating the unit. Then

plug all openings to keep out moisture, insects, etc.

4. Turn the flywheel by hand a few revolutions once a

month to distribute the oil.

5. Store the unit under a plastic wrap on its wooden

shipping base up off the ground. If the unit was

boxed for export shipment, leave it in its box. An

indoor or covered storage area is preferable.

6. When the compressor is to be put in service, vent

the remaining purge gas and change the crankcase

oil. See the "Pre-Startup Checklist" and "Startup

Procedure" sections in this manual.

Figure 16 – Pressurized Compressor Tag

•

Compressor is pressurized with inert gas.

CAREFULLY bleed off gas BEFORE

attempting any service.

Hazardous pressure can

cause property damage,

serious personal injury

or death.

Loading...

Loading...