MAINTENANCE

588/A page 12/24

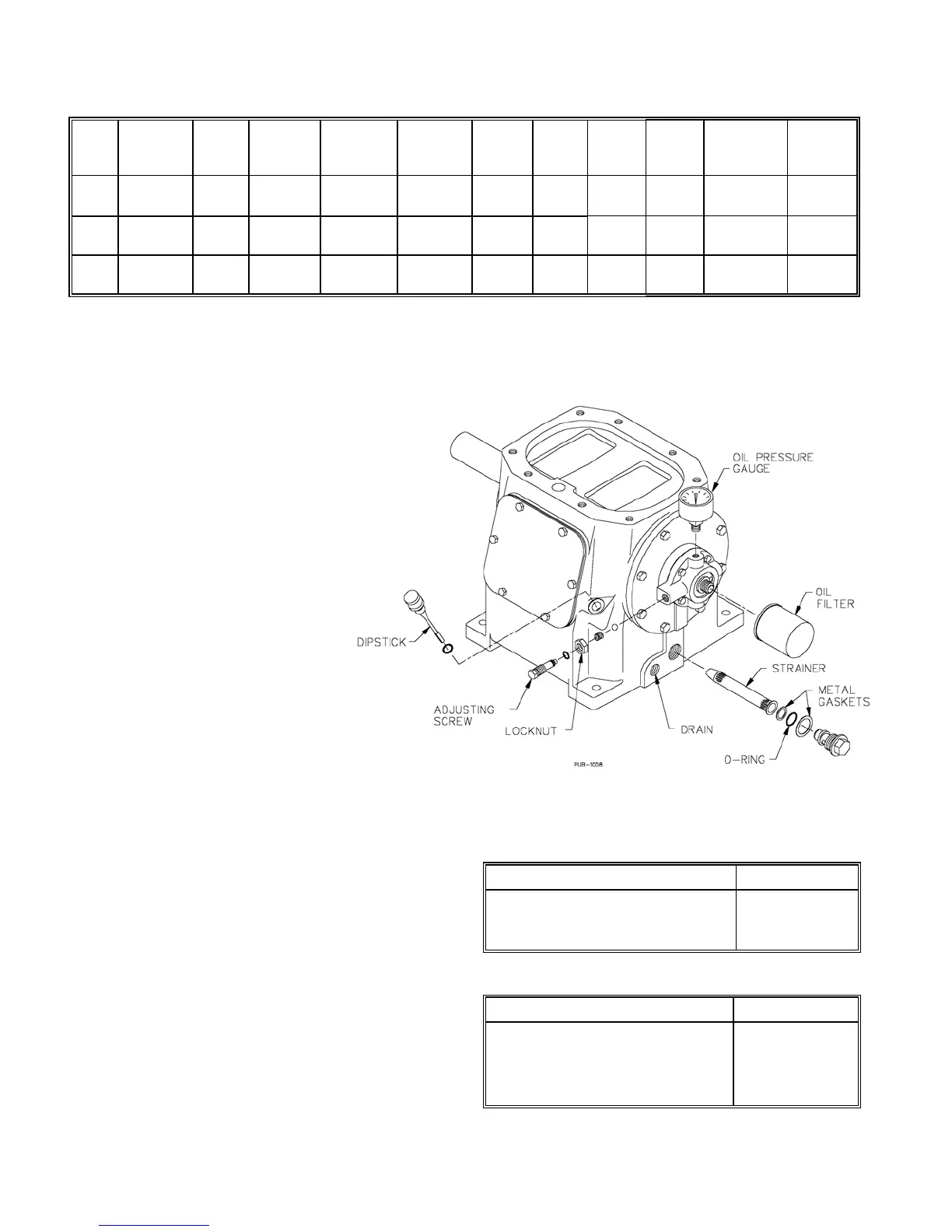

BOLT TORQUES FOR BLACKMER COMPRESSORS LBS-FT (Nm)

Size

Connecting

Rod Bolt

Bearing

Carrier

Bearing

Cover

Plate

Crankcase

Inspection

Plate

Crosshead

Guide

Cylinder Head

Piston

Nut

Valve

Cover

Plate

Valve

Hold Down

Screw

Valve

Cap

160

30

(40.7)

30

(40.7)

35

(47.5)

7

(9.5)

25

(33.9)

25

(33.9)

20

(27.1)

40

(54)

--

120

(163)

80

(108)

360

35

(47.5)

30

(40.7)

35

(47.5)

7

(9.5)

35

(47.5)

35

(47.5)

40

(54))

40

(54)

35

(47.5)

80

(108)

80

(108)

600

45

(61)

30

(40.7)

40

(54)

7

(9.5)

40

(54)

40

(54)

40

(54)

60

(81)

35

(47.5)

80

(108)

80

(108)

Table 7 - Bolt Torque

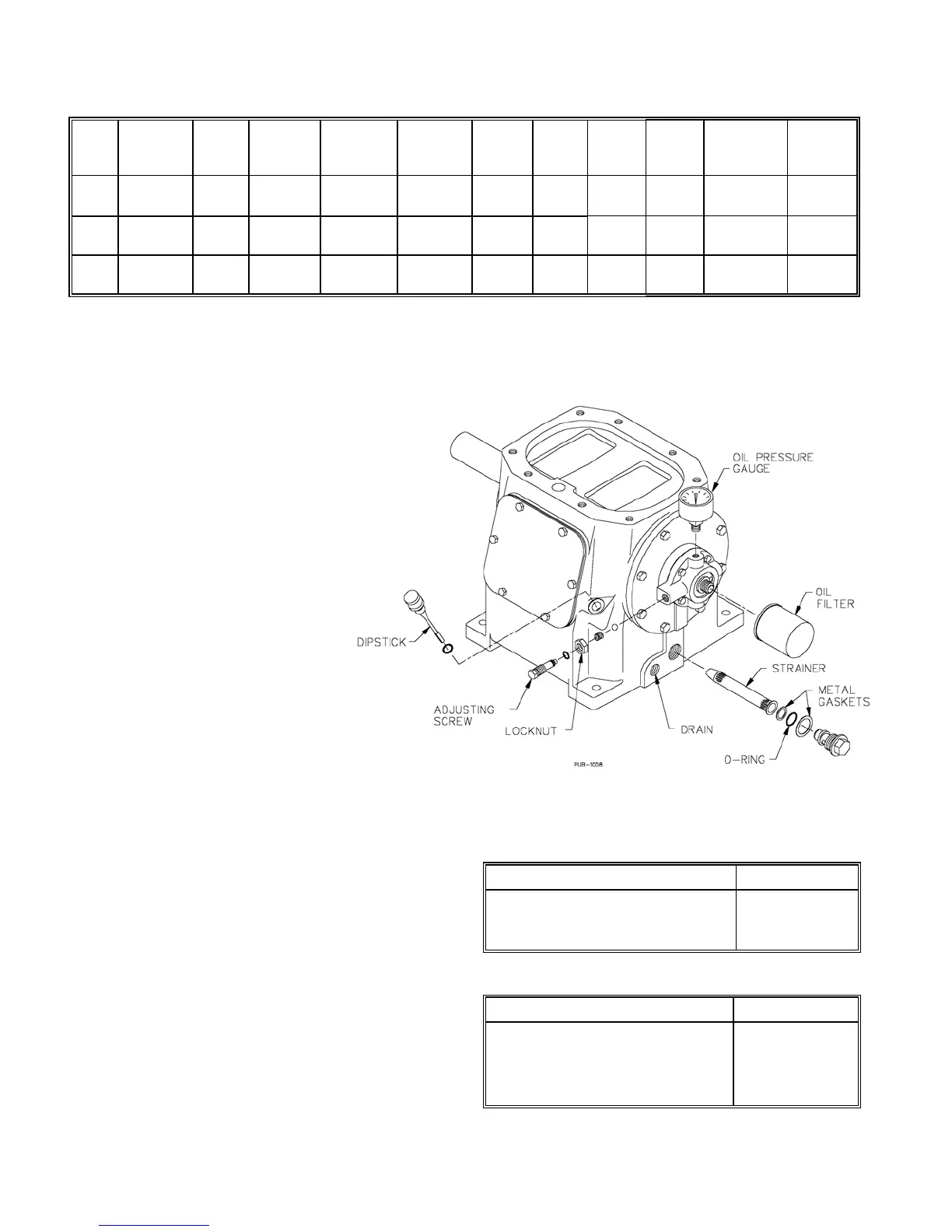

CRANKCASE LUBRICATION

Change the crankcase oil every 1,000

hours or 180 days, whichever is shorter.

Under severe dusty or sandy operating

conditions, the oil should be changed

every 500 hours or every 90 days.

A high quality non-detergent oil is

recommended. The oil used should

be of high quality such as API grade

SF, SG, SH or similar. API grade SA,

SB, SC or similar oils should never

be used. Recycled oils should

never be used.

Consult factory for special lubricating

requirements.

Before changing the oil, bring the

compressor up to normal operating

temperature. Remove the crankcase

drain plug and drain the oil into an

adequately sized container. Remove

the oil pickup screen and clean in a

suitable solvent. When reinstalling the

pickup screen, inspect the metal gasket

and the O-ring for damage, replacing as

necessary. If equipped, replace the

external oil filter. See Figure 8.

Refill the crankcase via the dipstick opening. DO NOT

OVERFILL THE CRANKCASE!

The oil pump on these models will operate in either

direction of crankshaft rotation.

SETTING THE OIL PRESSURE (see Figure 8)

1. The oil pressure should be about 25 psig

(173 KPa).

2. Loosen the locknut.

3. Increase the pressure setting by turning the

adjusting screw inward, CLOCKWISE.

Decrease the pressure setting by turning the

adjusting screw outward, COUNTER-CLOCKWISE.

4. Retighten the locknut.

Models Quarts

LB161B, LB162B

LB361B, LB362C

LB601B, LB602B

2

3

7

Table 8 - Oil Capacity

Air Temperature Oil Viscosity

Below 0°F (-18°C)

0 to 32°F (-18 to 0°C)

32 to 80°F (0 to 27°C)

80°F (27°C) and above

SAE 5W

SAE 10W

SAE 20W

SAE 30W

Table 9 - Oil Viscosity

Figure 8 - Compressor Lubrication System

Loading...

Loading...