101-B00 Page 8/16

VANE REPLACEMENT

NOTICE:

Maintenance shall be performed by qualified technicians

only. Follow the appropriate procedures and warnings

as presented in manual.

1. Flush the pump per instructions in this manual. Drain and

relieve pressure from the pump and system as required.

2. Remove the head assembly from the outboard

(nondriven) side of the pump according to steps 5 - 8 in

the "Pump Disassembly" section of this manual.

3. Turn the shaft by hand until a vane comes to the top (12

o'clock) position of the rotor. Remove the vane.

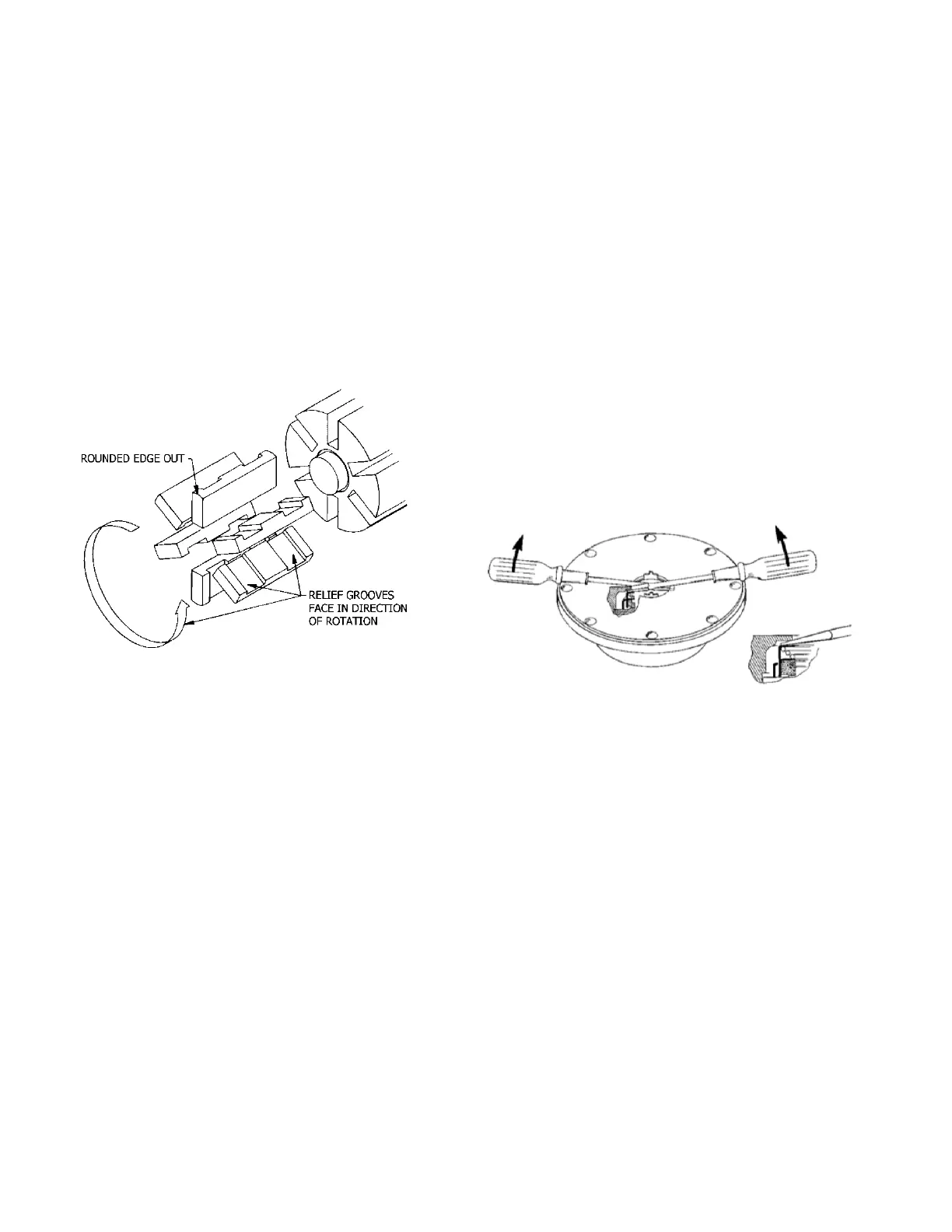

4. Install a new vane, ensuring that the rounded edge is UP,

and the relief grooves are facing towards the direction of

rotation. See Figure 4.

5. Repeat steps 3 and 4 until all vanes have been replaced.

6. Reassemble the pump according to the "Pump

Assembly." section of this manual.

Figure 4 – Vane Replacement

PUMP DISASSEMBLY

NOTICE:

Follow all hazard warnings and instructions provided in

the “Pump Maintenance” section of this manual.

1. Flush the pump per instructions in this manual. Drain and

relieve pressure from the pump and system as required.

2. On GX model pumps, disengage the motor shaft

coupling and remove the four clamp capscrews (20C) to

release the clamps (20B). Loosen the two setscrews (33)

in the gear reducer spool flange. The gear reducer can

then be rotated away from the motor shaft and lifted off

the pump. Refer to “Gear Reducer Maintenance” for

reducer disassembly instructions.

3. Starting on the inboard (driven) end of the pump, clean

the pump shaft thoroughly, making sure the shaft is free

of nicks and burrs. This will prevent damage to the

mechanical seal when the inboard head assembly is

removed.

4. On X/XH model pumps, remove the inboard bearing

cover capscrews (28) and slide the inboard bearing cover

(27A) and gasket (26) off the shaft. Discard the gasket.

On the X2 and X2.5-inch pump models, the dirt shield will

come off with the bearing cover. Inspect dirt shield and

replace as required.

5. Remove the outboard bearing cover capscrews (28) and

the outboard bearing cover (27) and bearing cover gasket

(26). Discard the bearing cover gasket.

6. X2.5, XH2.5, X3 and XH3 pump models are equipped

with locknuts (24A) and lockwashers (24B). To remove:

a. Bend up the engaged lockwasher tang and rotate the

locknut counterclockwise to remove it from the shaft.

b. Slide the lockwasher off the shaft. Inspect the

lockwasher for damage and replace as required.

c. Repeat steps a and b on the opposite shaft end.

7. X4/XH4 pump models are equipped with bearing lock

collars (24A). To remove:

a. Remove the jam nuts (24C) and loosen the two set

screws (24B).

b. Slide the lock collar off the shaft.

c. Repeat steps a and b on the opposite shaft end.

8. Remove the head capscrews (21). Gently pry the head

away from the cylinder.

9. Slide the head off the shaft. The head O-ring (72),

bearing (24), and mechanical seal (153) will come off with

the head assembly. Remove and discard the head O-

ring.

a. Pull the bearing (24) from the housing in the head.

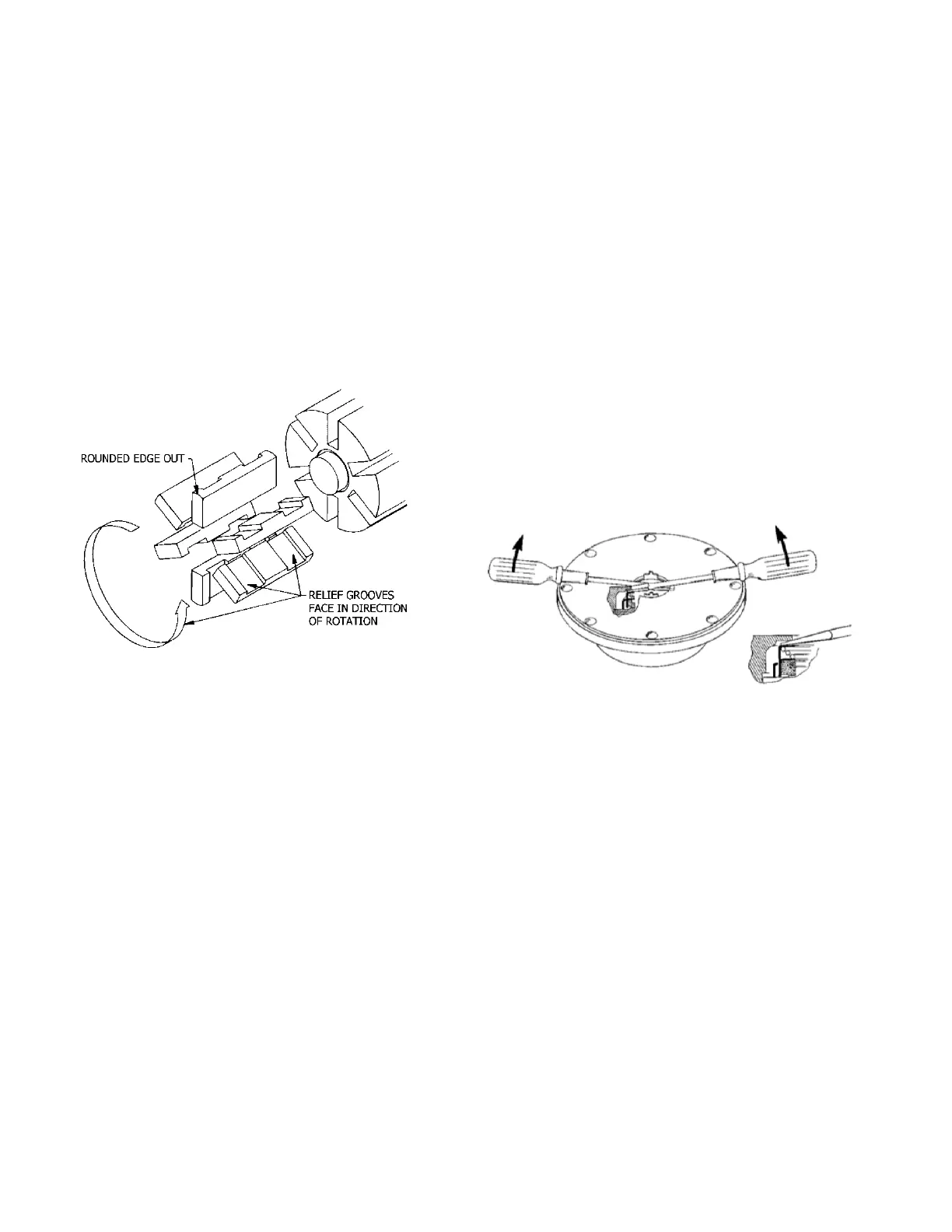

b. To remove the mechanical seal, use two screw

drivers against the backside of the seal jacket to

gently push the seal from the head (see Figure 5.

Use care when placing the screw drivers to prevent

damage to the seal faces. Remove and discard the

seal O-rings.

Figure 5 – Mechanical Seal Removal

10. Pull the rotor and shaft (13) from the cylinder. While one

hand is pulling the shaft, the other hand should be

cupped underneath the rotor to prevent the vanes (14)

and push rods (77) from falling out. Carefully set the rotor

and shaft aside for future vane replacement and

reassembly.

11. Remove the remaining components from the outboard

side of the pump, as instructed in steps 7 and 8 above.

PARTS REPLACEMENT

1. If any of the O-rings have been removed or disturbed

during disassembly, they be replaced with new O-rings.

NOTE: PTFE O-rings should be heated in hot water to

aid installation.

2. Excessive or continuous leakage from the tell-tale hole in

the bearing cover may be an indication of a damaged

mechanical seal. If a mechanical seal has been leaking, it

is recommended the entire seal be replaced. Refer to

"General Pump Troubleshooting" for possible causes of

seal leakage.

Loading...

Loading...