MAINTENANCE

OM 0277-A 18

DRIVELINE TROUBLESHOOTING

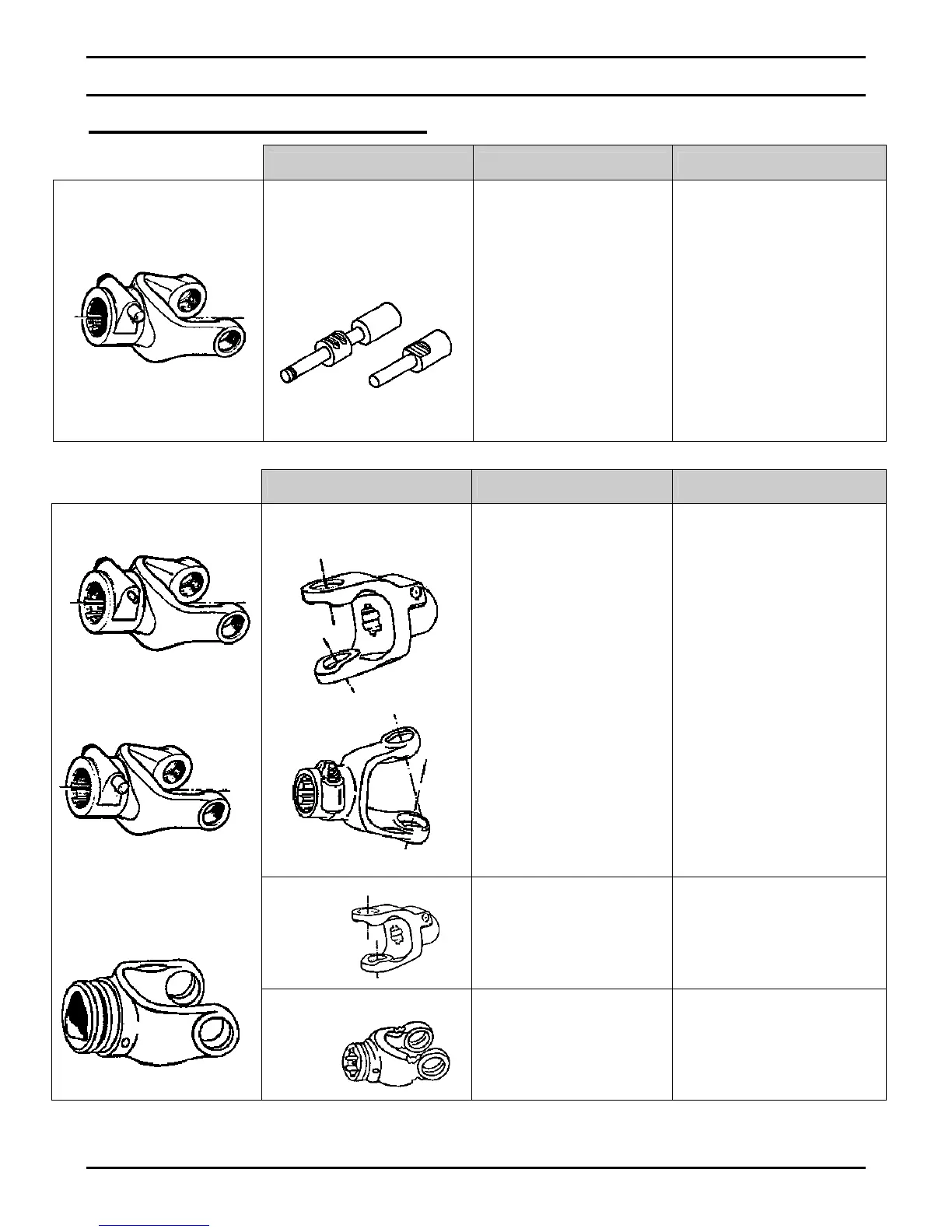

AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS

QUICK-DISCONNECT

YOKE

• Quick-disconnect pin tight

or completely seized.

• Quick-disconnect pin

damaged (broken or bent)

• Quick-disconnect pin

damaged in the locking

portion.

• Quick-disconnect pin

dirty (insufficient

maintenance).

• Quick-disconnect pin

defective (forced

engagement, incorrect

handling)

• Excessive shaft length.

• Axial loads too high.

• Clean, oil and follow service

instructions.

• Replace quick-disconnect

pin.

• Shorten shaft length (cut

both telescopic tubes as

well as shield and remove

burrs).

• Replace quick-disconnect

pin.

• Clean and grease

telescopic tubes, and

replace both tubes, if

necessary.

• Replace quick-disconnect

pin.

Note: Quick-disconnect pins must be cleaned and greased every 16 hours.

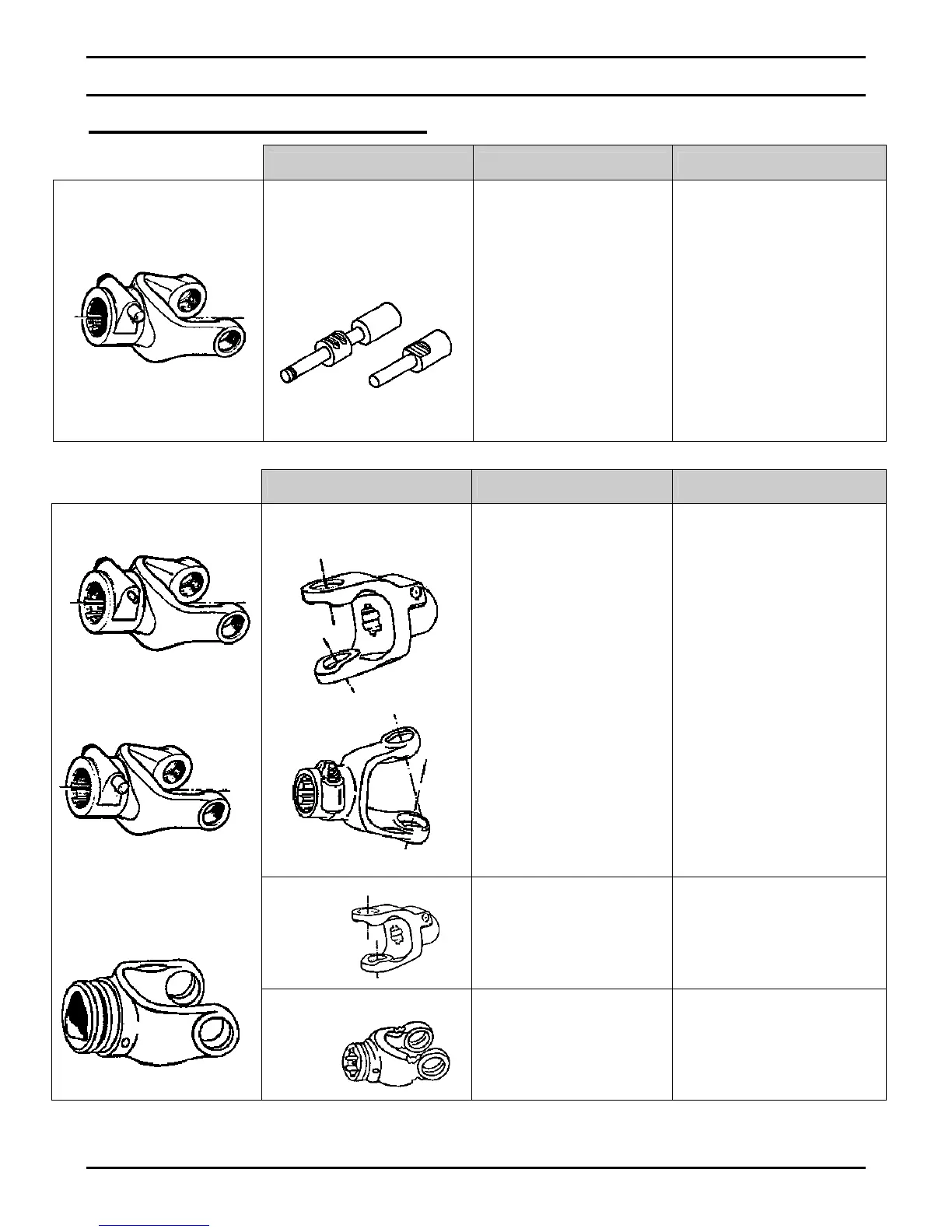

AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS

YOKE

• Yoke ears deformation

• Excessive shaft length.

• Axial loads too high.

• Excessive working angle

and torque.

• Shorten shaft length (cut

both telescopic tubes as well

as shields and remove

burrs).

• Replace defective yokes.

• Clean and grease telescopic

tubes, and replace both

tubes, if necessary.

• Replace defective yokes.

• Verify compatibility between

shaft and working conditions

(torque vs. angle).

• Disengage tractor driveline

during cornering or when

lifting or lowering the

implement.

• Change to a larger driveline

size.

• Replace defective yokes.

• Yoke ears distorted.

• Overload caused by high

starting and peak torques.

• Engage driveline more

carefully.

• Use appropriate safety

devices.

• Replace defective yokes.

• Yoke ears worn or

pounded.

• Excessive working angle. • Avoid excessive working

angle.

• Disengage tractor driveline

during cornering.

• Replace defective yokes.

Loading...

Loading...