MAINTENANCE

OM 0277-A 20

Note: Shield bearings must be greased every 8

working hours.

AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS

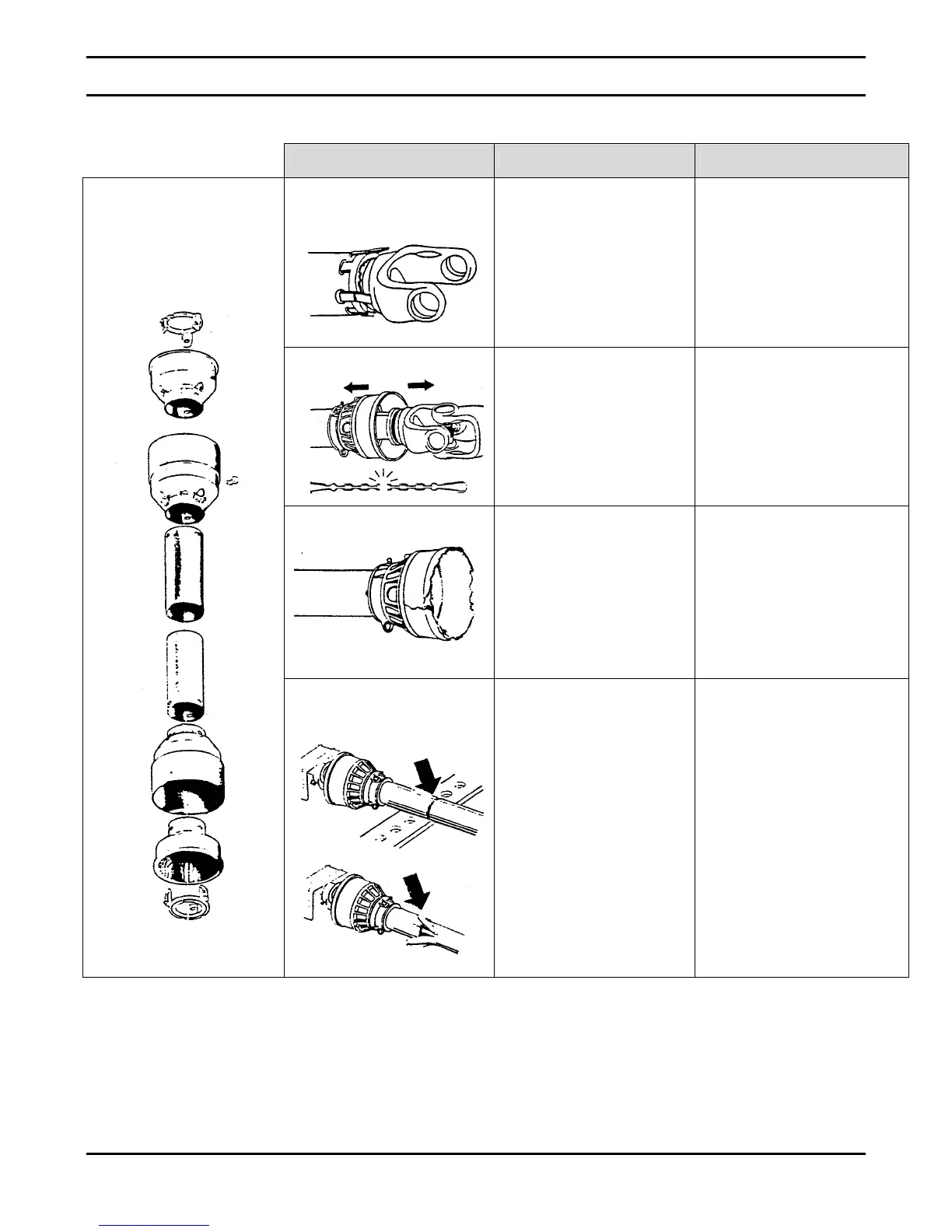

SHIELD

• Excessive wear of shield

bearings.

• Insufficient lubrication.

• Incorrect chain mounting.

• Shield interfering with

implement.

• Follow lubrication

instructions.

• Mount chain to allow

maximum angularity.

• Avoid contact of the shields

with fixed parts of the

machine or tractor.

• Replace shield bearings.

• Chain moving or failure.

! Shield interfering with

implement.

! Incorrect chain mounting.

• Avoid contact of the shields

with fixed parts of the

machine or tractor.

• Mount chain to allow

maximum angularity.

• Replace defective parts.

• Shield cone damaged.

• Shield cone in contact

with components on the

tractor and/or implement.

• Excessive angularity.

• Eliminate interference

between Shield cones and

any part on the tractor

and/or implement.

• Avoid excessive angle

during cornering or when

lifting or lowering the

implement.

• Replace damaged Shield

cones.

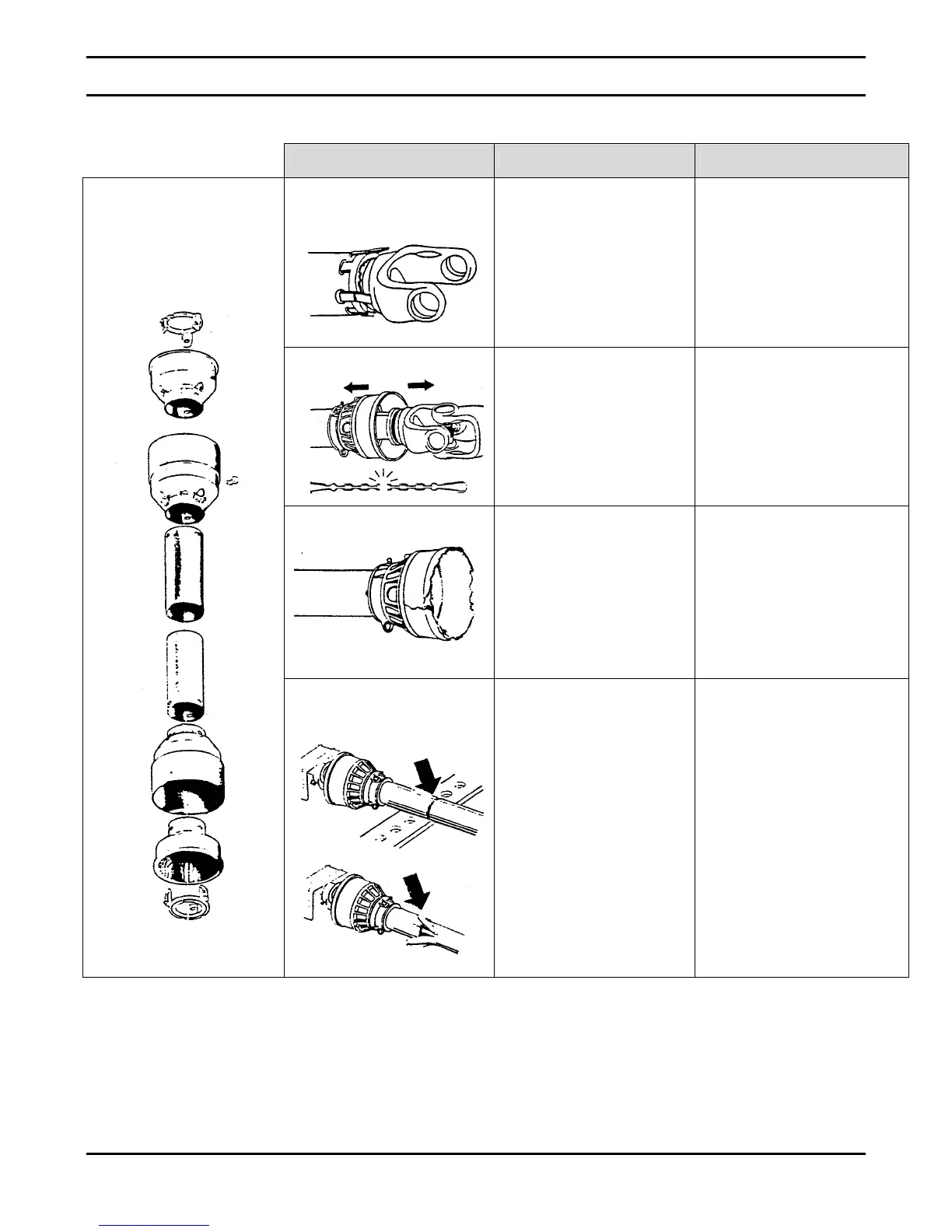

• Shield tubes damaged

(deformed and split at one

side).

• Shields in contact with

components on the tractor

and/or implement.

• Shield tubes overlap too

short or no overlap at all

with extended driveline.

• Eliminate interference

between Shield cones and

any part on the tractor

and/or implement.

• Replace damaged tubes.

• Adjust Shield tubes length

with longer tubes.

Loading...

Loading...