BLT481 Product Manual

5.2 Specific operation process

5.2.1 Preparation of clean bench

Prepare the clean bench, start it up and ensure its functionality:

1. Check that the equipment is clean and qualified (checks the cleanliness of the dust particle counter ), and confirm

that the FFU purification unit is within the validity period (measure the average wind speed in the working area, when the

wind speed cannot reach 0.3m/s, the FFU purification unit must be replaced);

2. Check whether each switch is running normally, and check whether the fan is running normally;

3. It is strictly forbidden to install unnecessary items in the clean working area to ensure that the clean air flow is

not disturbed;

4. For clean workbenches that are newly installed or have not been used for a long time, please use a clean cloth

and anhydrous ethanol to wipe them clean before use;

During operation:

1. Turn on the power, and pull the glass sliding door of the clean workbench to the lowest position (leaving a gap

of about 10cm);

2. Start the fan, it is recommended to purify the clean table for about 30 minutes in advance;

3. Turn on the light source of the clean workbench.

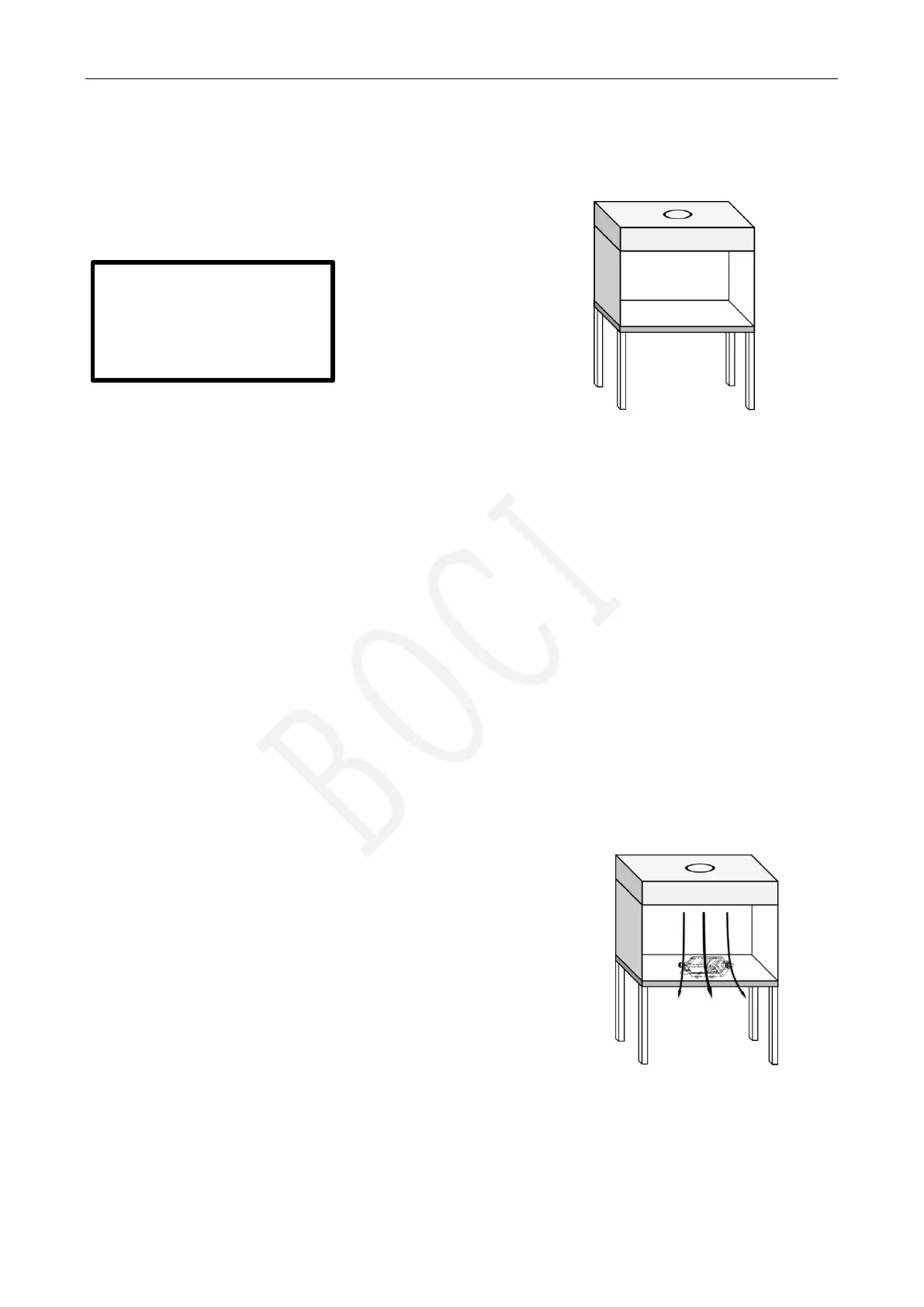

5.2.2 The cutting head is placed in the clean workbench

Put the cutting head horizontally inside the clean workbench.

Clean table type: vertical

purification; cleanliness class: ISO

5, 100; average wind speed ≥

0.4m/s

Notice:

To prevent dust from contaminating the core area of the

cutting head, please ensure the integrity of the special

protective film/cap for the optical fiber interface before

plugging and unplugging the optical fiber.

Loading...

Loading...