Liquid Cooling ACU / ANG /AEC

6.4.2 Coolant supply control

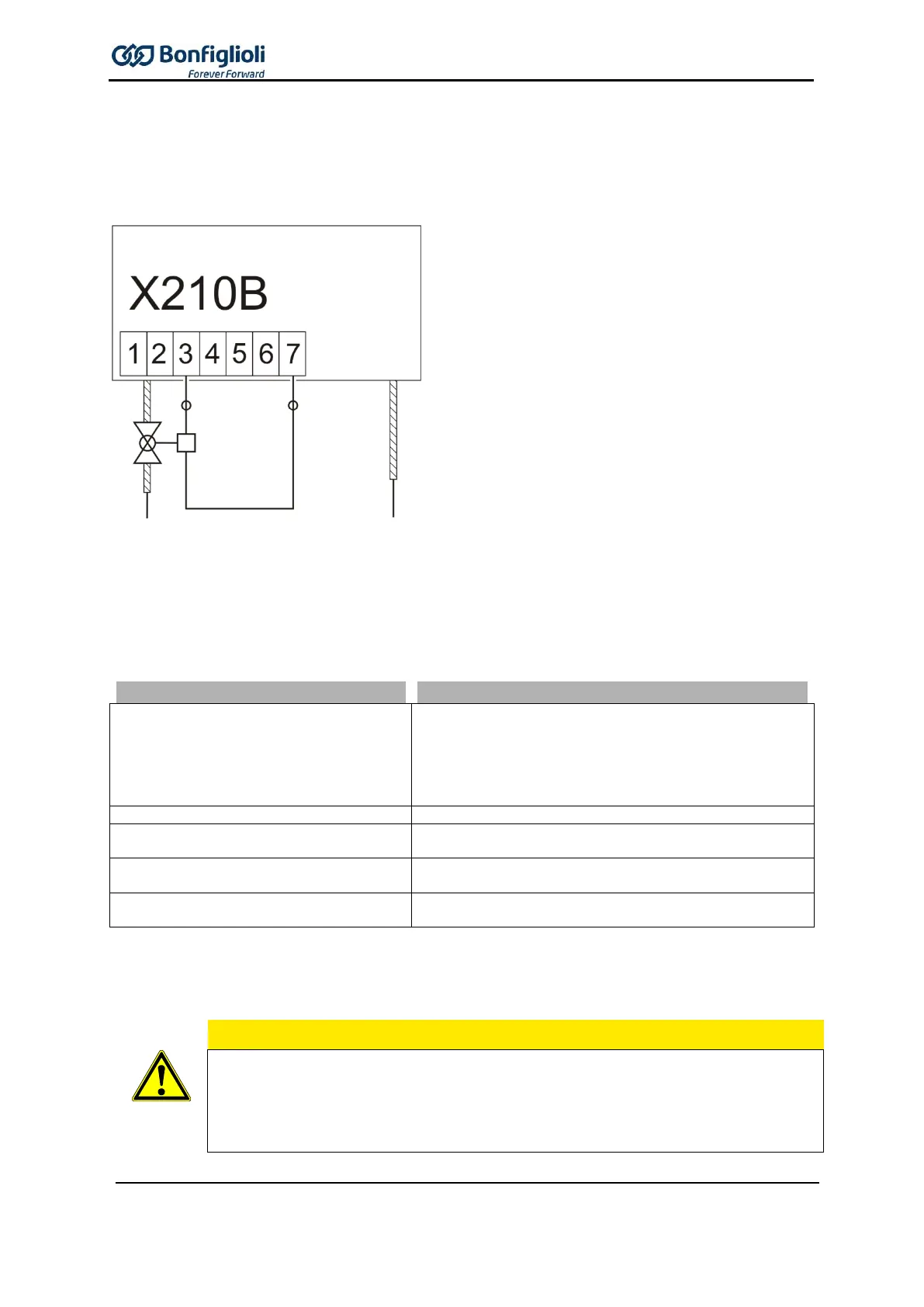

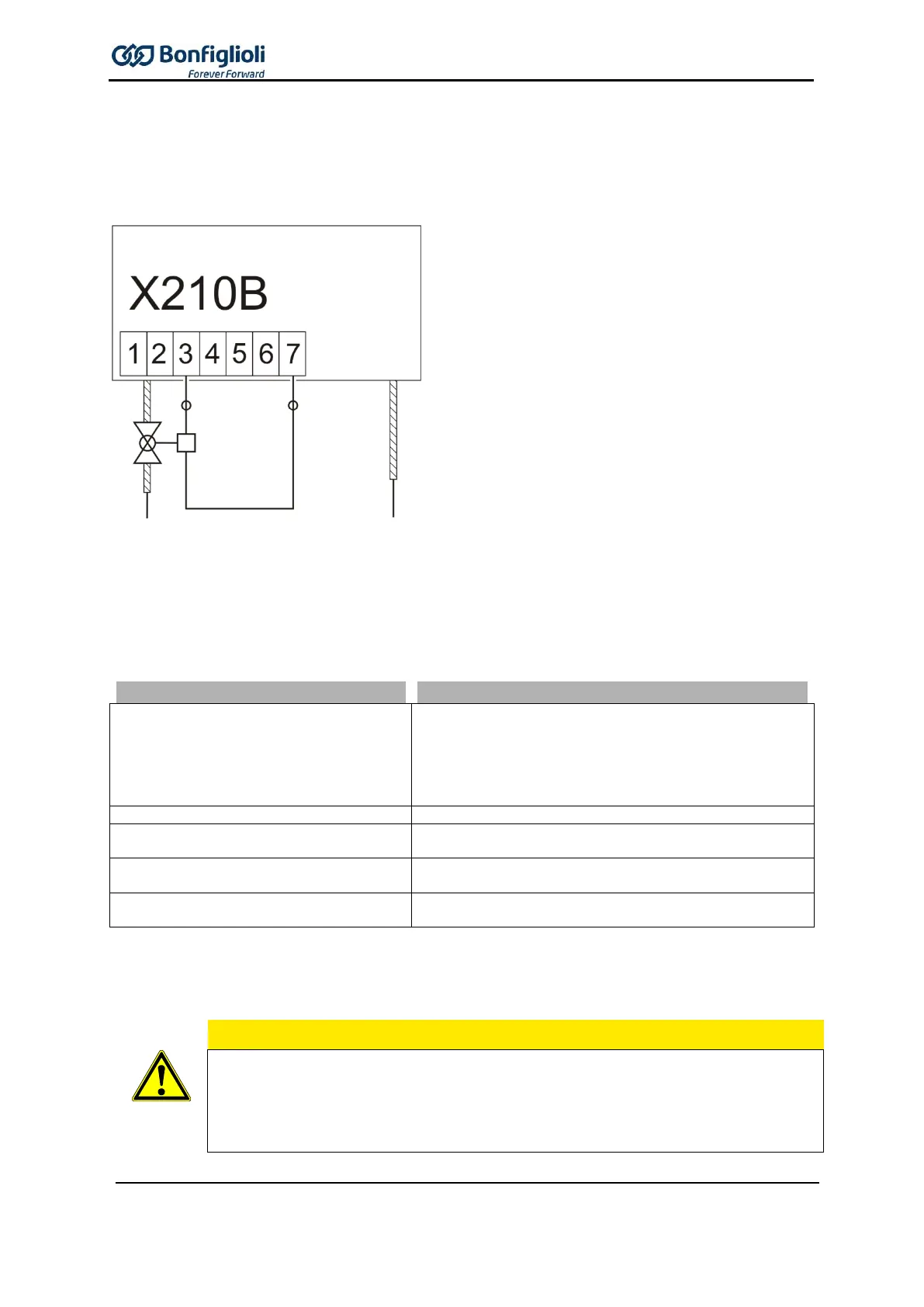

The manufacturer recommends integrating a solenoid valve in the coolant supply line to control the

volumetric flow rate. The solenoid valve is controlled via a digital output with transistor output or a

multifunction output.

6.5 Measures against soiling of coolant and frost

The coolant must be chemically neutral and free from abrasive and other solids. It must not be aggres-

sive on the material. For the coolant quality, refer to Chapter 4.4 "Hydrologische Daten".

The user shall take appropriate precautions against soiling and furring-up, e.g. by installing an inlet

filter.

Typical soiling and common precautions include:

Use of the following filters:

Sieve filter

Gravel filter

Cartridge filter

Precoat filter

Softening of coolant by ion exchange

Moderate content of mechanical soiling and

hardeners

Addition of stabilizers or dispersing agents to coolant

Moderate content of chemical

soiling

Addition of passivating or inhibiting agents to coolant

biological impurities,

mucous bacteria and algae

Addition of biocides to coolant

If the heat sink or coolant are exposed to temperatures below 5°C, an appropriate frost protection agent

must be added to the coolant.

Device damage

Insufficient coolant quality can result in clogging up and/or corrosion of the heat sink and

impair the function of the frequency inverter cooling system. This can result in frequency

inverter damage.

Ensure sufficient coolant quality.

Loading...

Loading...