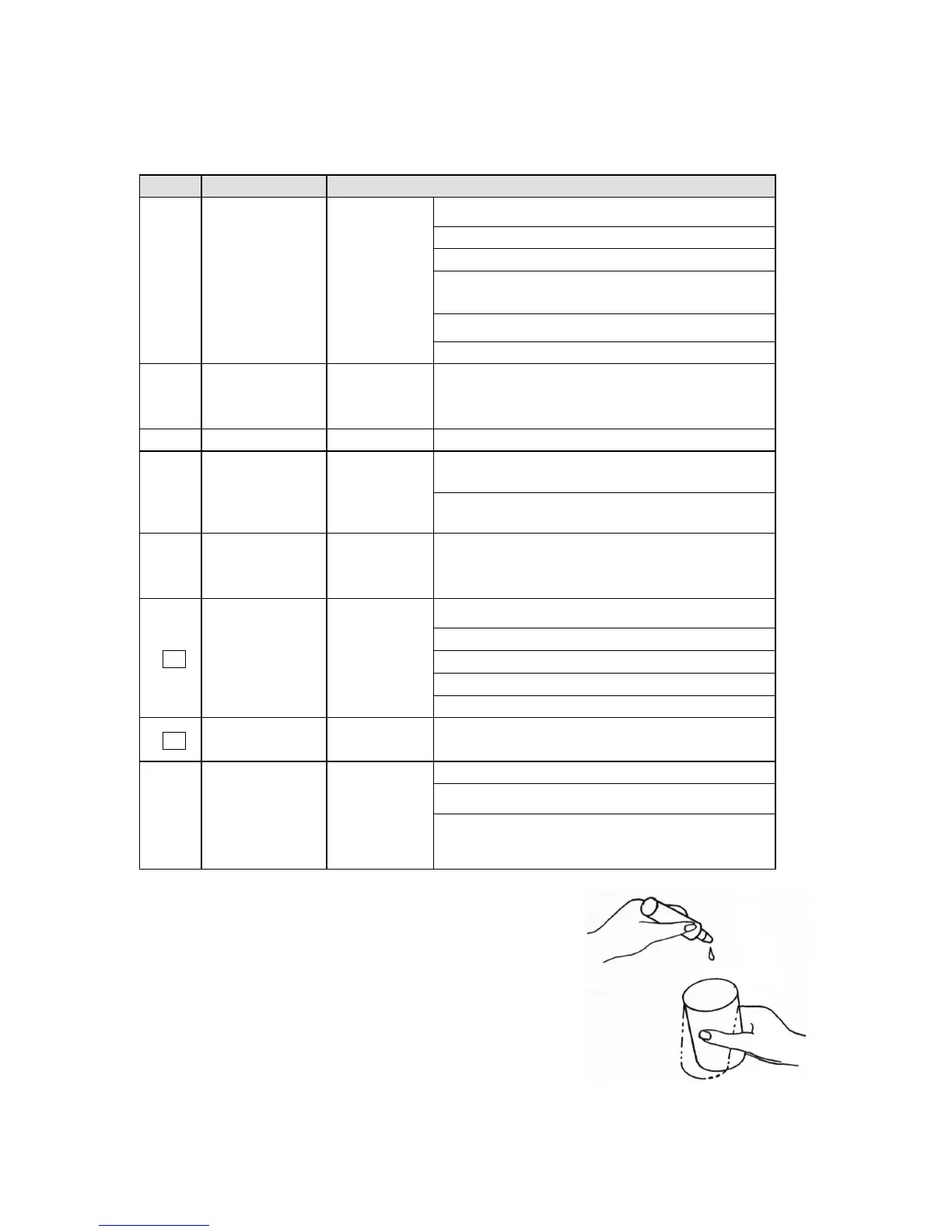

2) Indication Method

Symbol

Indication Power failure or Cause for operation stop

Damper limit switch shut off

Leakage detection failure

Fuse cut-off, not reached up to the high water level

Protect relay operation error due to moisture( Remove

moisture by dry air)

Manipulation switch failure

◀

Operation No operation

without power

failure

Power failure

Suspected flame signal

▲

Combustion

position)

Combustion is

not performed

continuously

Limit switch open(short)

P

Suspected flame signal

■

Circuit check for

flame detector in the

control

Power failure

Control system failure

▼

Damper close(1st.

combustion

preparation)

No operation

continuously

Damper limit switch close(shut off)

Check the polarity of the flame detector

Ignition transformer failure

Fuel valve failure

Lack of flame stability

1

1st. safety time Power failure

Flame detector failure

2

2nd. safety time Power failure

Ignition failure of the burner(1st. solenoid valve shut off or

too much air volume)

Weak flame current

Fuel supply suspension

―

·

·

·

―

(2nd combustion)

Operation

Power failure

Abnormal operation of the flame detector(QRA-2), Clean

dust on the glass surface or flame-eye(P-930 -5)

3-2 Brief Maintenance and Cleaning Method

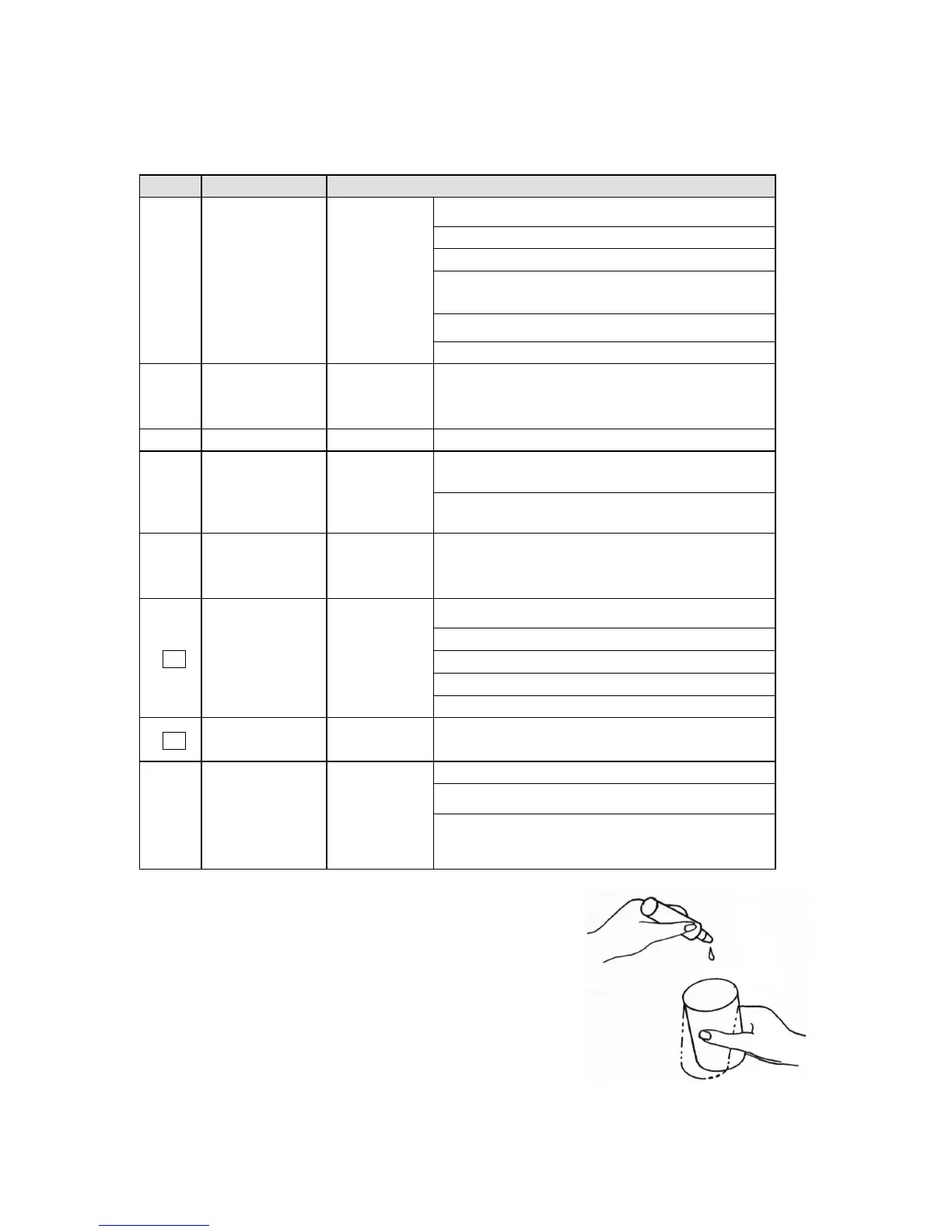

(1) Check for Soft Water

The followings are to be checked for the boiler durability:

1) Feed water must be soft water.

2) Soft water quality must be checked by the hardness indicator at least

once a day. (About 30 -50cc water in the container taken from the softener

outlet is examined by dropping the hardness indicator).

(Soft Water Check)

Loading...

Loading...