Chapter 5 Boiler Water Treatment

5-1 Boiler Water Treatment

For a longer boiler life and for maintaining continuous good operation condition, appropriate water treatment is

required like a food control for our health. The hard water such as tap water and underground water includes various

foreign substance. Therefore the softener or chemicals(tube cleaning detergent) which changes the hard water to soft

water shall be used. Especially, boiler damage due to bad quality of water is not able to be identified immediately.

Therefore, daily water check and control is very important

* When using underground water, the feed water filter must be used.

(1) Boiler Harm by the water

The boiler water including the hardening elements(Ca, Mg) and silica causes high water concentration and scale

attachment to the tube wall. Since thermal conductivity of the scale is extremely low, the boiler efficiency is reduced

which is caused of boiler superheating. Corrosion of steel is caused by acid and alkali water. If the boiler tube is

corroded, the thickness of tube is to be thinned by damaging of surface and come to rupture. Conclusively, the boiler

harm by the water is the scale and corrosion.

(2) Scale Protection

1) Softener Use

The boiler water is to be the soft water which is removed the hardening elements of Ca and Mg dissolved in the water

which become to the scale by the softener.

2) Chemical Use

(BOOSTER Cleaning Detergent: Direct Heating - 182 ppm for general use, Indirect Heating - 98

ppm for industrial use)

The chemical is injected for protection that the small amount of hardening elements and silica in the water leaked

from the softener become to scale, and of corrosion of tube by removing the dissolved oxygen in the water to

maintain the water in the alkalinity(PH:11.0 - 11.8) which is the most difficult condition for corrosion).

* Chemical Injection Method

The chemical should be injected continuously during operation by the chemical injection device balanced with the

amount of feed water from the feed water pump.

*

Relation between Scale and Tube Wall Temperature

*

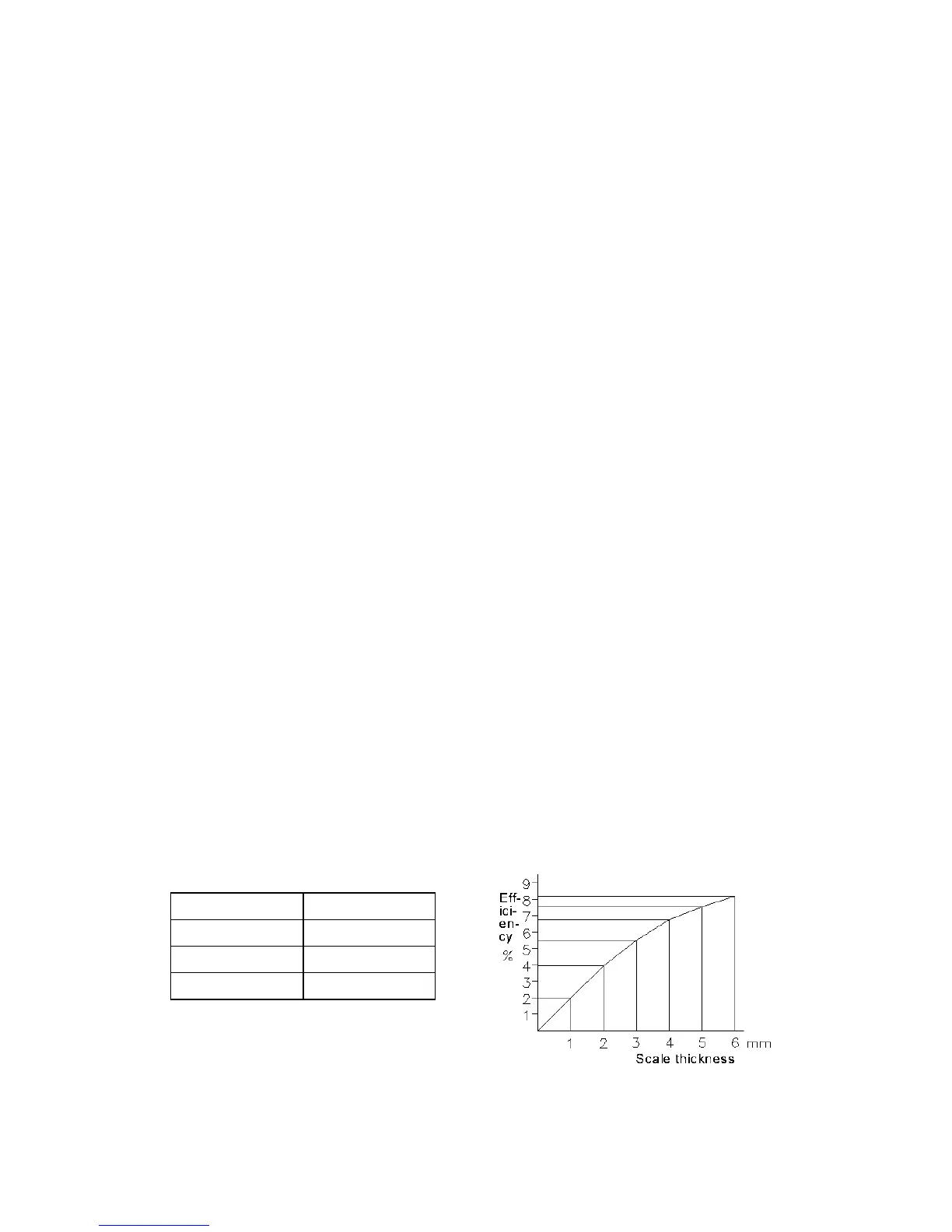

Boiler Efficiency Reducing by Scale

* Exceeding the tube temperature 350°C, the allowable stress is dropped down rapidly.

Thickness of Scale

Loading...

Loading...